Synthesis method for cotton defoliant

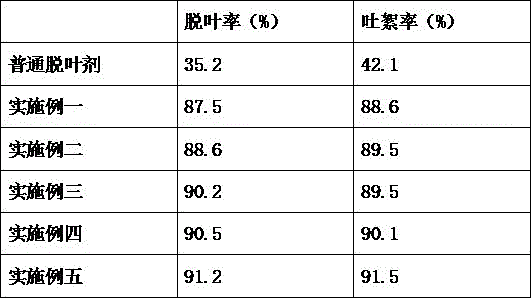

A synthesis method and technology of defoliants, which are applied in the fields of botanical equipment and methods, biocides, animal repellants, etc., can solve problems such as environmental pollution and polluted soil, and achieve the improvement of defoliation rate, prevention of oxidative deterioration, prolongation of The effect of storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The ratio of the ingredients used is: 20 parts of ethephon, 20 parts of magnesium chlorate, 15 parts of paclobutrazol, 10 parts of coronatin, 10 parts of pyraclofen, 2 parts of carrageenan, 15 parts of sodium lignosulfonate, carboxymethyl 5 parts of sodium cellulose, 2 parts of nano silver ion powder and 25 parts of deionized water.

[0018] In this embodiment, ethephon is ethephon with a mass percentage of 45%.

[0019] The synthetic method of the present embodiment comprises the following steps:

[0020] A. After mixing ethephon, magnesium chlorate and paclobutrazol, add 1 / 3 deionized water, carry out mechanical stirring, the stirring speed is 2000 rpm, the stirring time is 15min, and obtain the A mixture after standing;

[0021] B. Mix coronatine, pyraclofen, and carrageenan in A mixture evenly, then pour it into a heating container for heating, the heating temperature is 35°C, and the heating time is 3 minutes to obtain B mixture;

[0022] C. Add sodium lignosulfo...

Embodiment 2

[0025] The proportion of ingredients used is: 25 parts of ethephon, 25 parts of magnesium chlorate, 17 parts of paclobutrazol, 11 parts of coronatin, 12 parts of metazafen, 3 parts of carrageenan, 16 parts of sodium lignosulfonate, carboxymethyl 6 parts of sodium cellulose, 3 parts of nano silver ion powder and 27 parts of deionized water.

[0026] In this embodiment, ethephon is ethephon with a mass percentage of 47%.

[0027] The synthetic method of the present embodiment comprises the following steps:

[0028] A. After mixing ethephon, magnesium chlorate and paclobutrazol, add 1 / 3 deionized water, carry out mechanical stirring, the stirring speed is 2200 rpm, the stirring time is 16min, and obtain the A mixture after standing;

[0029] B. Mix coronatine, pyraclofen, and carrageenan in A mixture evenly, and then pour it into a heating container for heating. The heating temperature is 35°C and the heating time is 3.5 minutes to obtain B mixture;

[0030] C. Add sodium ligno...

Embodiment 3

[0033] The proportion of ingredients used is: 40 parts of ethephon, 50 parts of magnesium chlorate, 25 parts of paclobutrazol, 15 parts of coronatin, 20 parts of metazafen, 6 parts of carrageenan, 20 parts of sodium lignosulfonate, carboxymethyl 12 parts of sodium cellulose, 6 parts of nano silver ion powder and 45 parts of deionized water.

[0034] In this embodiment, ethephon is ethephon with a mass percentage of 65%.

[0035] The synthetic method of the present embodiment comprises the following steps:

[0036] A. After mixing ethephon, magnesium chlorate and paclobutrazol, add 1 / 3 deionized water, carry out mechanical stirring, the stirring speed is 3000 rpm, the stirring time is 20min, and obtain the A mixture after standing;

[0037] B. Mix coronatine, pyraclofen, and carrageenan in A mixture evenly, then pour it into a heating container for heating, the heating temperature is 35°C, and the heating time is 5 minutes to obtain B mixture;

[0038] C. Add sodium lignosulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com