Magnetic compound bone cement and preparation method for same

A bone cement and magnetic technology, which is applied in the preparation of magnetic bone cement and magnetic bone cement, and the preparation of magnetic composite bone cement, can solve the problems of poor degradation performance and non-degradation of bone cement matrix, and reduce the exothermic temperature and collapse properties, good magnetic and heat generation properties, and the effect of reducing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

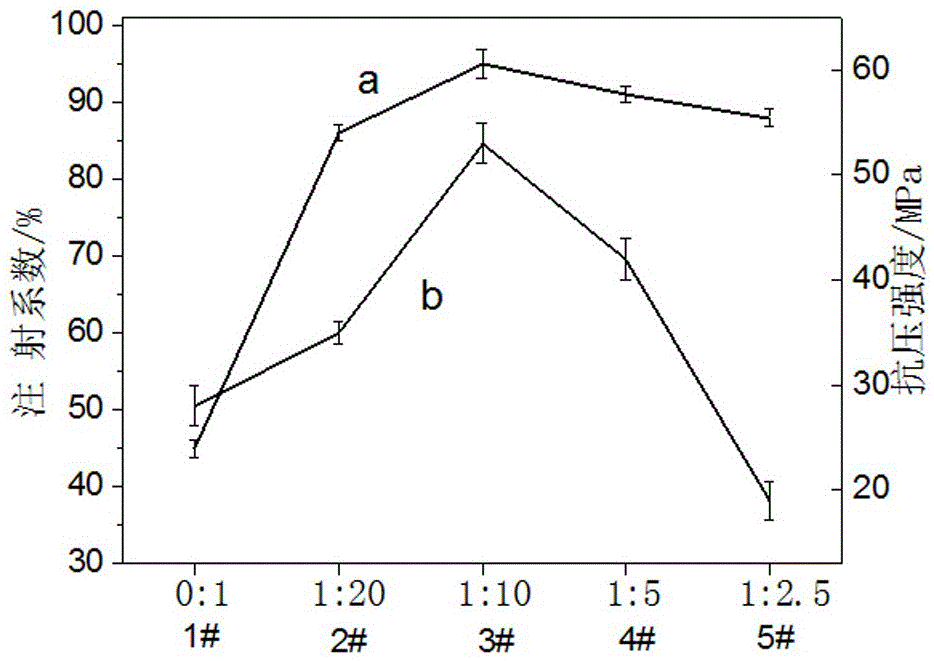

Examples

Embodiment 1

[0035] 1. Preparation of DMSA-wrapped zinc-doped superparamagnetic ferric oxide nanoparticles

[0036] FeSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.73×10 -3 mol Fe 2+ and 2.67×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and magnetically stir at room temperature until a uniform solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230° C. for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles rep...

Embodiment 2

[0049] 1. Preparation of DMSA-wrapped zinc-doped superparamagnetic ferric oxide nanoparticles

[0050] FeSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.73×10 -3 mol Fe 2+ and 2.67×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and magnetically stir at room temperature until a uniform solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230° C. for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles rep...

Embodiment 3

[0063] 1. Preparation of DMSA-wrapped zinc-doped superparamagnetic ferric oxide nanoparticles

[0064] FeSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and ZnSO 4 Dissolve in 20ml of water so that the precursor reaches 1.73×10 -3 mol Fe 2+ and 2.67×10 -4 mol Zn 2+ the goal of. Next, mix 10ml of oleic acid, 10ml of water and 1g of NaOH, and magnetically stir at room temperature until a uniform solution is obtained. Furthermore, the precursor Fe 2+ and Zn 2+ Pour into this homogeneous solution, and after stirring for a few minutes, the mixed solution turns dark brown. Finally, the solution was transferred into a 50ml reaction kettle, sealed, and heated at 230° C. for 15 hours. After the reaction, cool to room temperature. The product is deposited at the bottom of the kettle, and the nanoparticles are taken out by dissolving with cyclohexane. Then add ethanol into the cyclohexane containing the nanoparticles to precipitate the nanoparticles, and finally wash the nanoparticles rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com