Separation type acoustic agglomeration suspended fine particle emission reduction system based on resonant cavity

A separation and acoustic agglomeration technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of insufficiency of the system, high energy consumption and operating cost of the system, and large site space, etc. The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with drawings and embodiments.

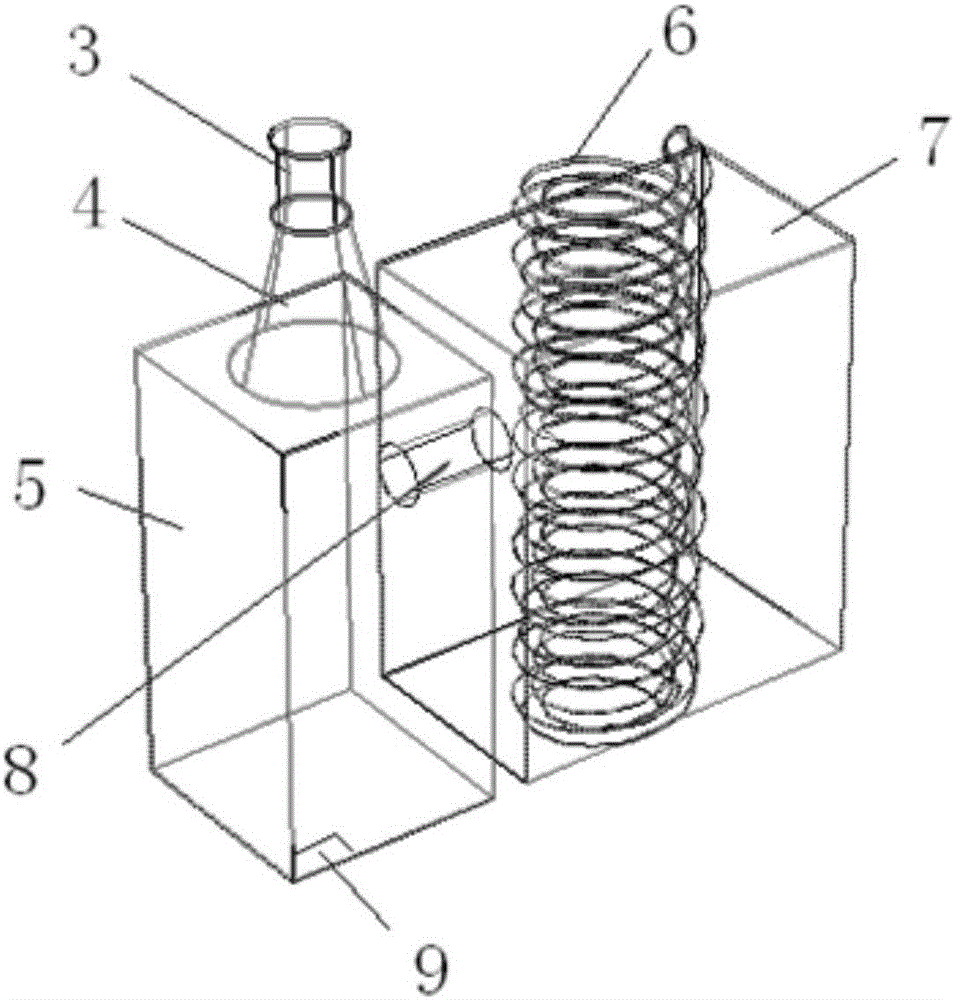

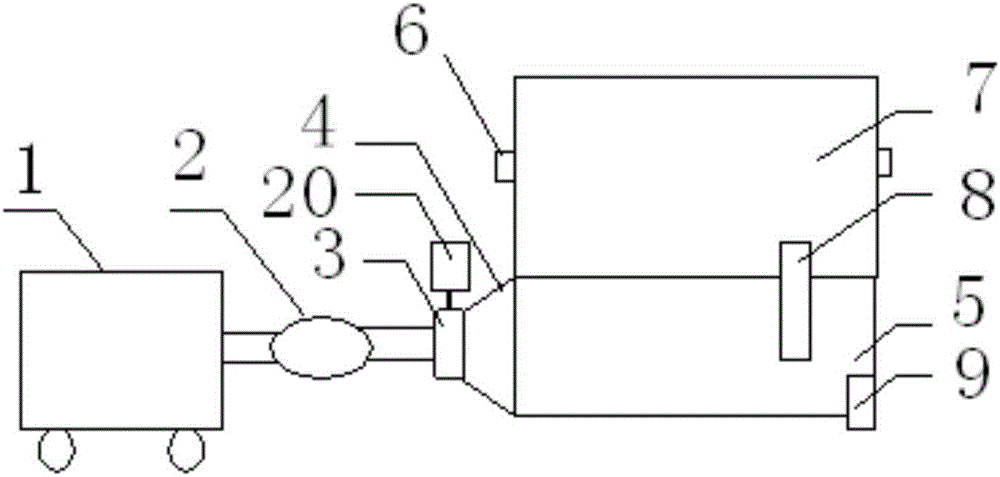

[0077] see figure 1 , a closed coupling chamber 5 is coupled to the resonant reunion chamber 7 through a length-adjustable short tube 8, and the closed coupling chamber 5 is connected to the electric-pneumatic modulation sounding head 3 through an index type cylinder 4, and the electric-pneumatic modulation sounding head 3 is connected with A signal generator and power amplifier 20; a small-diameter exhaust port 9 is provided on the closed coupling cavity 5; a curved thin-walled pipe 6 is provided in the resonant reunion chamber 7 . The wall thickness of the curved thin-walled pipe 6 is 2 mm to 4 mm.

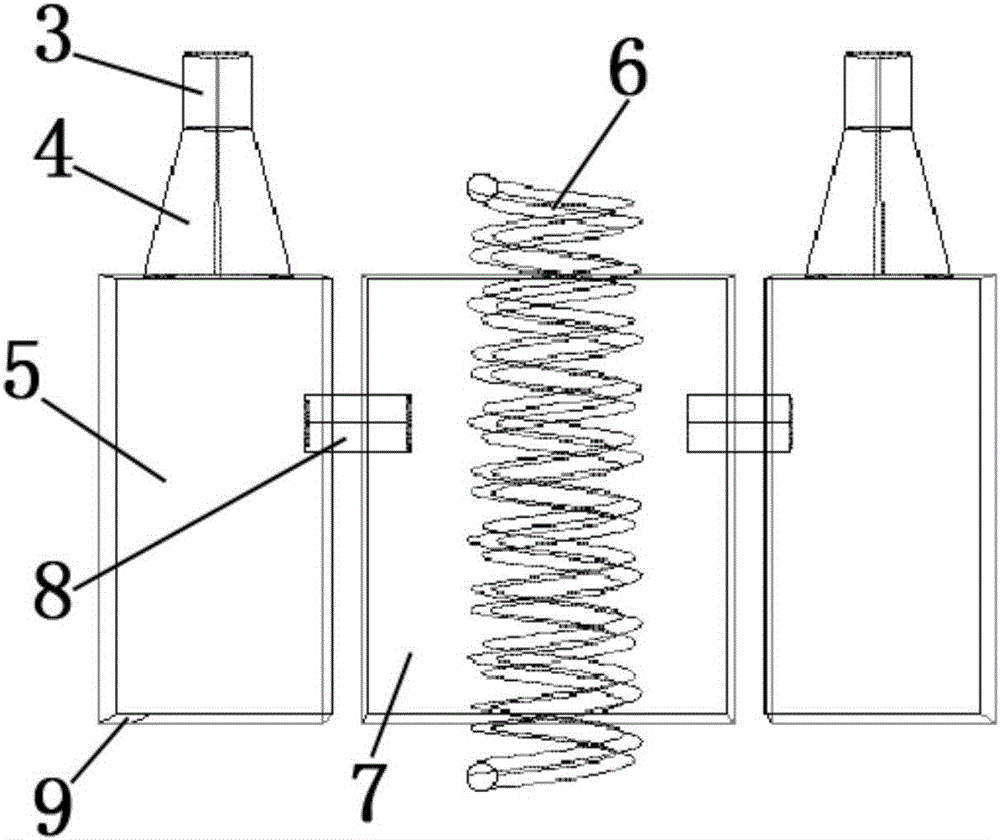

[0078] see figure 2 , a closed coupling cavity 5 is coupled to the resonant reunion chamber 7 through a length-adjustable short tube 8, and the closed coupling cavity 5 is connected to the electric-pneumatic modulation sounding head 3 through an index type tube 4; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com