A preparing method and a product of a heavy metal adsorption material for a polluted water body

An adsorption material and heavy metal technology, which is applied in the field of preparation of heavy metal adsorption materials in polluted water, can solve the problems of high toxicity and poor control of modification conditions, and achieve good adsorption capacity and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

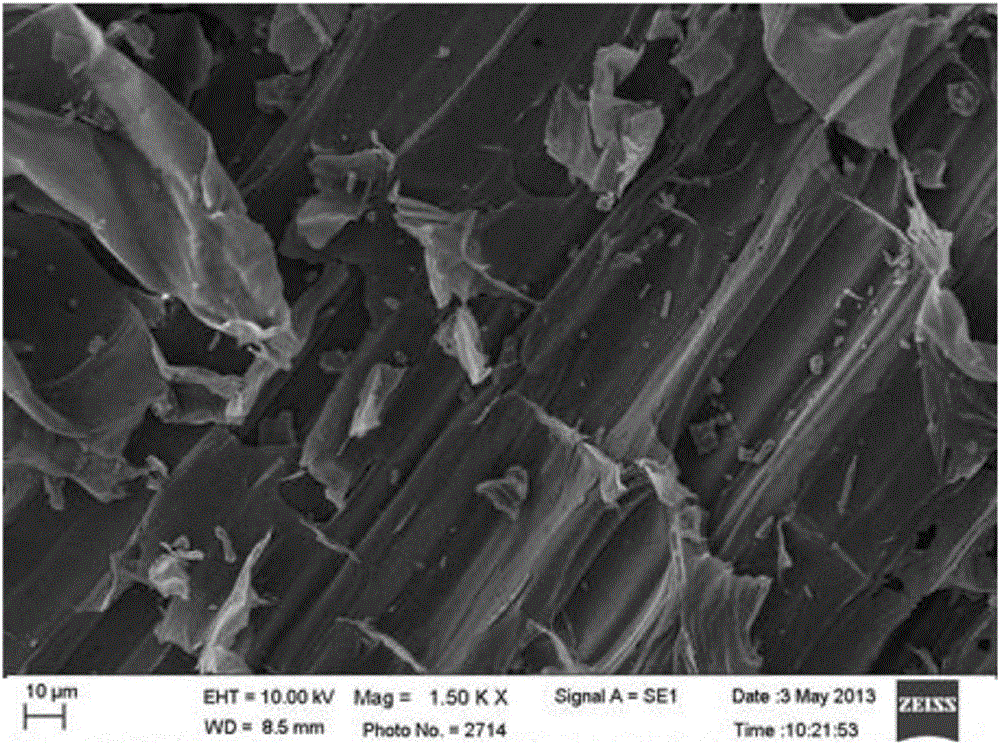

[0035] A preparation method of heavy metal adsorption material in polluted water, the steps are:

[0036] 1) The straw is washed, dried, pulverized, sieved and sieved;

[0037] 2) The sieved powder is completely submerged in alkali solution for soaking treatment;

[0038] 3) The treated sample is separated by suction filtration from solid to liquid, washed with water, and then drained;

[0039] 4) The sample in the previous step is immersed in acrylonitrile for etherification treatment;

[0040] 5) suction filter the etherified sample to remove excess acrylonitrile;

[0041] 6) Immerse the sample in the previous step into the enamine / ethylene glycol system for amination treatment

[0042] 7) Suction filter the aminated sample, rinse with water several times, and drain;

[0043] 8) Immerse the sample in the previous step into the hydroxylamine hydrochloride and potassium carbonate solution system, and heat to carry out the oximation reaction;

[0044] 9) Suction filter the...

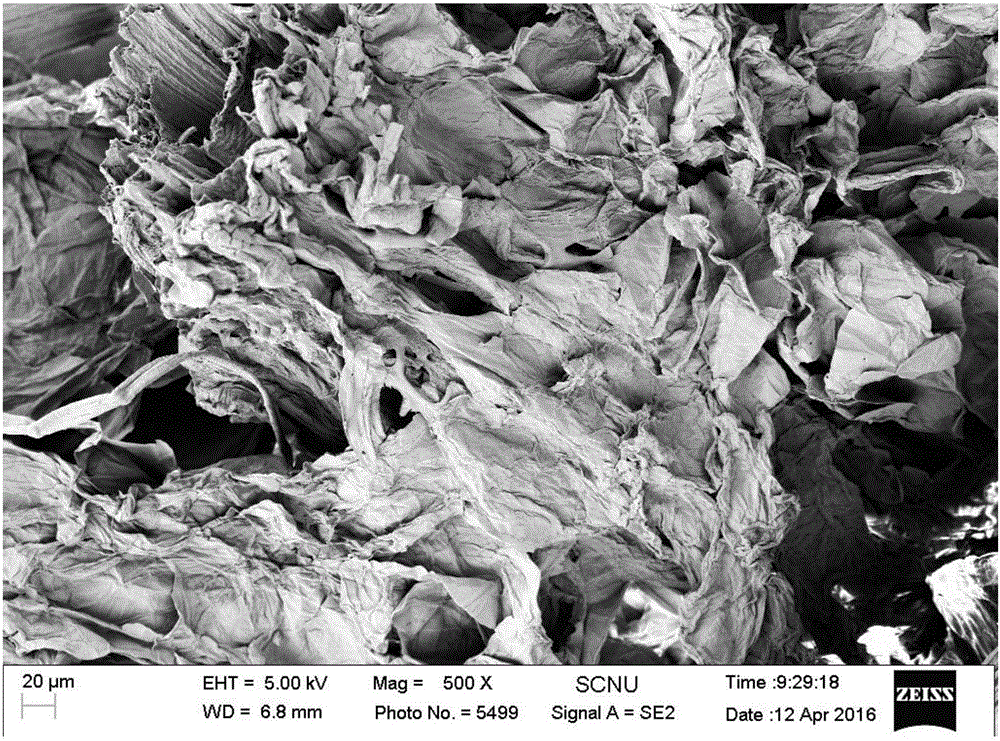

Embodiment 1

[0057] A preparation method of heavy metal adsorption material in polluted water, the steps are:

[0058] 1) The straw is washed, dried, crushed, and sieved through a 20-mesh sieve;

[0059] 2) Completely immerse the sieved powder in 1mol / L potassium hydroxide solution, and soak for 24 hours at room temperature;

[0060] 3) The treated sample is separated by solid-liquid suction filtration, washed with pure water, and then drained;

[0061] 4) Immerse the sample in the previous step in acrylonitrile with a mass concentration of 90%, and perform an etherification reaction at 30° C. for 1 hour;

[0062] 5) suction filter the etherified sample to remove excess acrylonitrile;

[0063] 6) Immerse the sample in the previous step into the diethylenetriamine / ethylene glycol system at a ratio of 1:30; amination reaction at 80°C for 3 hours;

[0064] 7) Suction filter the aminated sample, rinse with water several times, and drain;

[0065] 8) Immerse the sample in the previous step ...

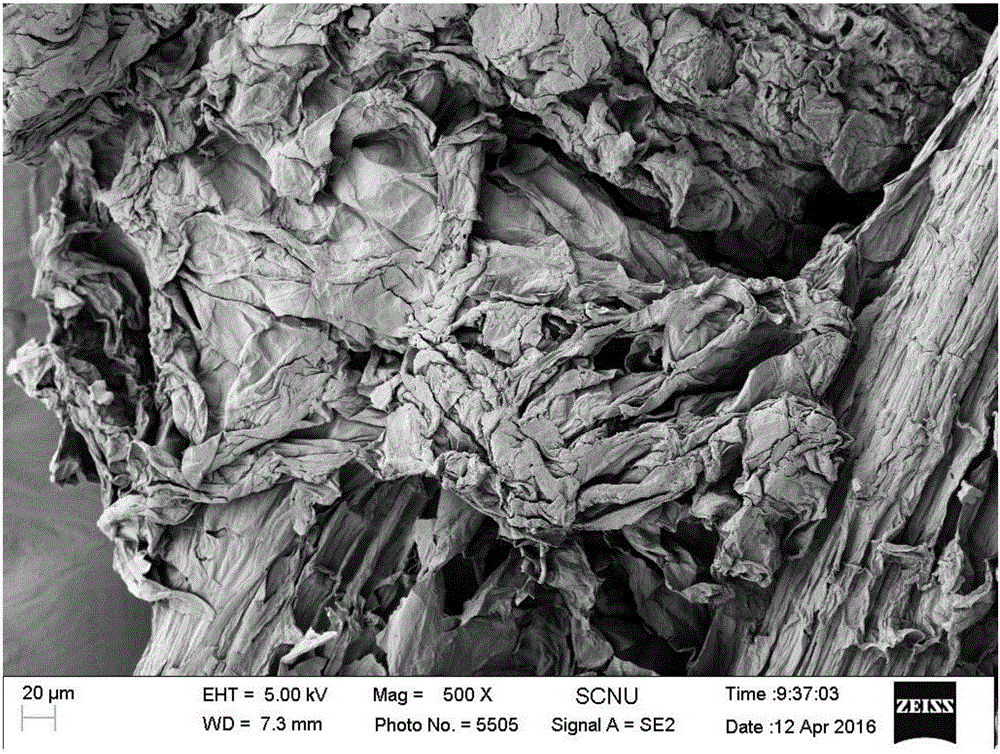

Embodiment 2

[0069] A preparation method of heavy metal adsorption material in polluted water, the steps are:

[0070] 1) The straw is washed, dried, crushed, and sieved through a 20-mesh sieve;

[0071] 2) Completely immerse the sieved powder in 2mol / L potassium hydroxide solution, and soak for 36 hours at room temperature;

[0072] 3) The treated sample is separated by solid-liquid suction filtration, washed with pure water, and then drained;

[0073] 4) Immerse the sample in the previous step in acrylonitrile with a mass concentration of 70%, and perform an etherification reaction at 50° C. for 1 hour;

[0074] 5) suction filter the etherified sample to remove excess acrylonitrile;

[0075] 6) Immerse the sample in the previous step into the triethylenetetramine / ethylene glycol system with a ratio of 1:20; amination reaction at 60°C for 5 hours;

[0076] 7) Suction filter the aminated sample, rinse with water several times, and drain;

[0077] 8) Immerse the sample in the previous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com