Porous ionic/molecular imprinted polymer preparation method

A technology of molecular imprinting and ion imprinting, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of single adsorption target and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

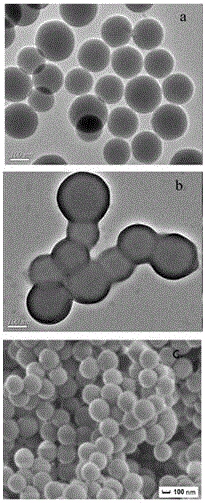

[0032] (1) Preparation of silica nanoparticles (SPs)

[0033] First, 90 mL of ethanol, 3.14 mL of water, and 3.14 mL of concentrated ammonia were added into a 250 mL round bottom flask under magnetic stirring. After stirring for 5 minutes, 3.14 mL of tetraethyl silicate (TEOS) was added dropwise thereto, and the mixture was o The reaction was continued for 0.5 h at C, and the stirring speed was maintained at 700 rpm. Subsequently, the reaction product was recovered by high-speed centrifugation, washed with methanol at least three times, and then washed at 50 o C under vacuum for 12 h.

[0034] (2) Preparation of ion-imprinted polymer nanoparticles (IIPs)

[0035] First, 0.154 g copper chloride (CuCl 2 ) was dissolved in 16 mL of methanol and stirred by a magnet, then 0.69 mL of N-aminoethyl-3-aminopropyltrimethoxysilane (DAMO) was added, and the mixed solution was continuously stirred and heated at 40 o C under reflux for 0.5 h, and then add 30 mL of silicon dioxide metha...

Embodiment 2

[0043] (1) Preparation of silica nanoparticles (SPs)

[0044] First, 90 mL of ethanol, 10 mL of water, and 3.14 mL of concentrated ammonia were added into a 250 mL round bottom flask under magnetic stirring. After stirring for 10 minutes, 6.0 mL of tetraethyl silicate (TEOS) was added dropwise, and the mixture was o The reaction was continued for 1.0 h at C, and the stirring speed was maintained at 700 rpm. Subsequently, the reaction product was recovered by high-speed centrifugation, washed with methanol at least three times, and then washed at 60 o C under vacuum for 12 h.

[0045] (2) Preparation of ion-imprinted polymer nanoparticles (IIPs)

[0046] First, 0.154 g copper chloride (CuCl 2 ) was dissolved in 16 mL of methanol and stirred by a magnet, then 0.8 mL of N-aminoethyl-3-aminopropyltrimethoxysilane (DAMO) was added, and the mixed solution was continuously stirred and heated at 45 o C under reflux for 1.0 h, and then add 34 mL of silicon dioxide in methanol disp...

Embodiment 3

[0050] (1) Preparation of silica nanoparticles (SPs)

[0051] First, 90 mL of ethanol, 12.56 mL of water, and 3.14 mL of concentrated ammonia were added into a 250 mL round bottom flask under magnetic stirring. After stirring for 15 minutes, 9.42 mL of tetraethyl silicate (TEOS) was added dropwise, and the mixture was o The reaction was continued for 2.0 h at C, and a stirring speed of 700 rpm was maintained. Subsequently, the reaction product was recovered by high-speed centrifugation, washed with methanol at least three times, and then washed at 70 o C under vacuum for 12 h.

[0052] (2) Preparation of ion-imprinted polymer nanoparticles (IIPs)

[0053] First, 0.154 g copper chloride (CuCl 2 ) was dissolved in 16 mL of methanol and stirred by a magnet, then 0.847 mL of N-aminoethyl-3-aminopropyltrimethoxysilane (DAMO) was added, and the mixed solution was continuously stirred and heated at 50 o C under reflux for 1.5 h, and then add 40 mL of silicon dioxide in methanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com