A preparation method of zero-valent iron-carbon nanotube modified zeolite composite material

A carbon nanotube modification and composite material technology is applied in the field of preparation of zero-valent iron-carbon nanotube modified zeolite composite materials, which can solve the problems of many sources of waste water, environmental hazards, large discharge and the like, and achieves a simple preparation process. , the effect of improving efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

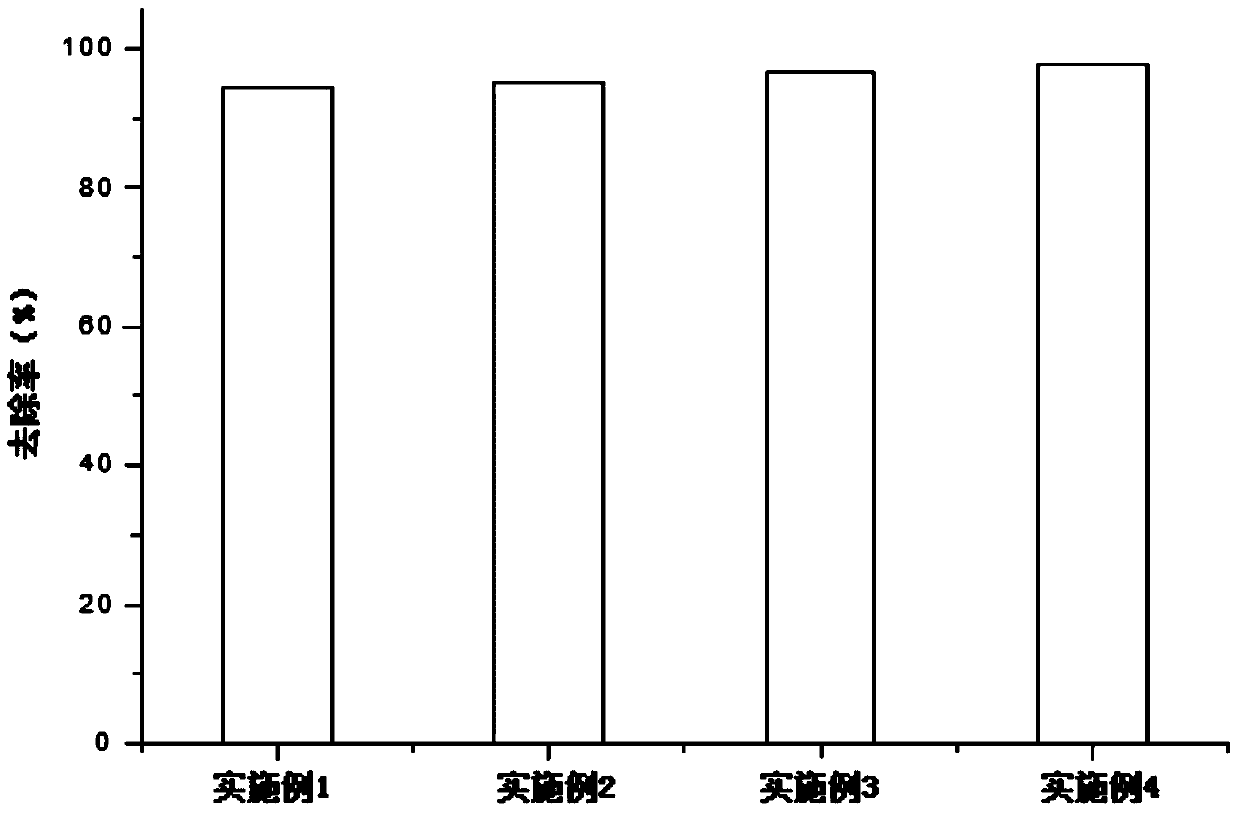

Embodiment 1

[0025] Disperse 20 g of artificial zeolite 5A in 300 mL of 10 mol / L NaOH solution, and stir at 110° C. for 7 hours to form a hydrogel. Then add 2g of zero-valent iron / carbon nanotubes (mass ratio 1.5:1), stir evenly, put the material into a polytetrafluoroethylene-lined reactor, and crystallize at 99°C for 3-4 hours. Then filter, wash, and dry at 60°C for 24 hours.

Embodiment 2

[0027] 13X zeolite is mixed with sodium hydroxide solution, wherein, the concentration of sodium hydroxide solution is 10mol / L, and the volume-to-weight ratio (mL solution / g zeolite) of sodium hydroxide solution and zeolite is 5:1, after fully mixing, in 100 The hydrogel was prepared by reacting at ℃ for 24 hours; the hydrogel was mixed with 2g of zero-valent iron / carbon nanotubes (mass ratio 1.5:1), crystallized at 105℃ and autogenous pressure for 24 hours, and then separated , washing and drying steps to obtain the sample.

Embodiment 3

[0029] P zeolite is mixed with potassium hydroxide solution, wherein, the concentration of potassium hydroxide solution is 5mol / L, and the volume-to-weight ratio (mL solution / g zeolite) of sodium hydroxide solution and zeolite is 10:1, after fully mixing, in 100 The hydrogel was prepared by reacting at ℃ for 3 hours; the hydrogel was mixed with 2g of zero-valent iron / carbon nanotubes (mass ratio 1.5:1), crystallized at 110℃ and autogenous pressure for 24 hours, and then separated , washing and drying steps to obtain the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com