Cutting-off machine for making bone samples

A technology for cutting machine tools and samples, which is applied in the field of tiny cutting machine tools for preparing small samples of biological bones, can solve the problems of time-consuming and labor-intensive, and reduce processing accuracy, and achieve the effects of uniform thickness, reduction of types, and guarantee of shape accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following will combine Figure 1 to Figure 6 The specific technical solution of the present invention is described in detail.

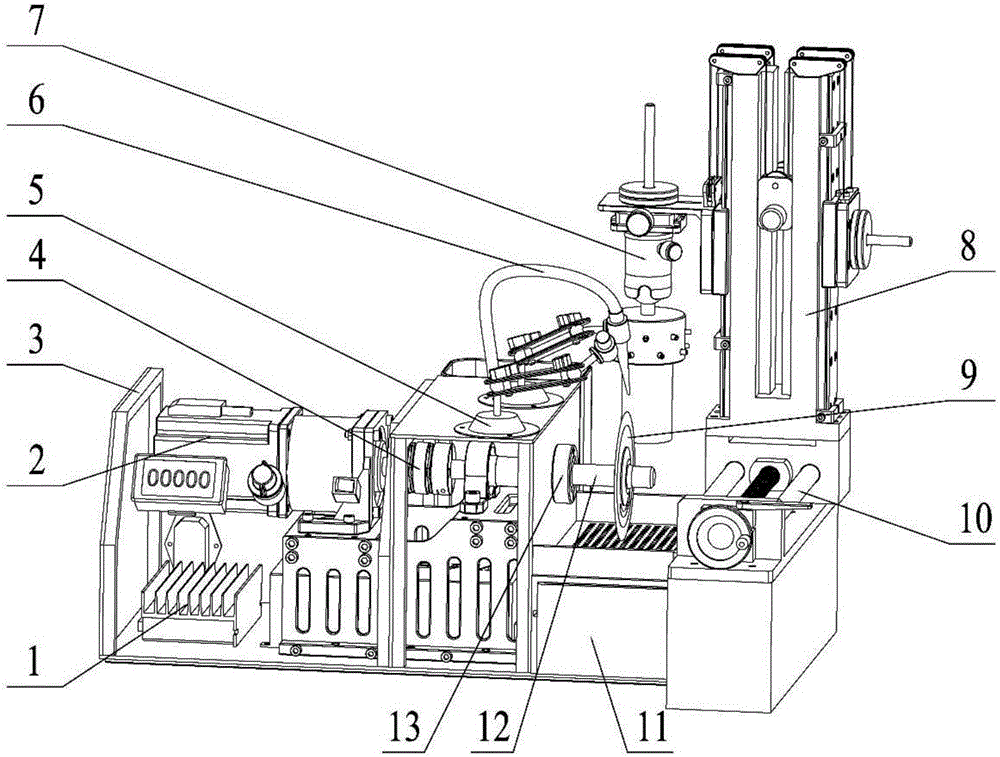

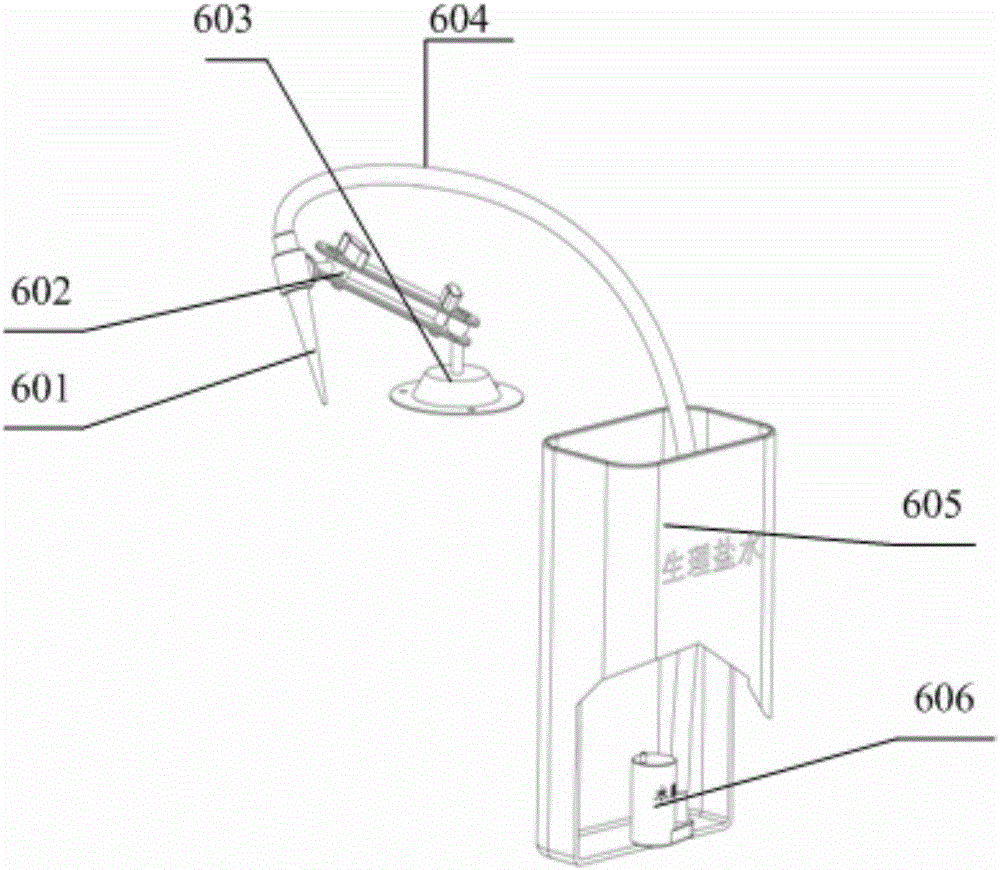

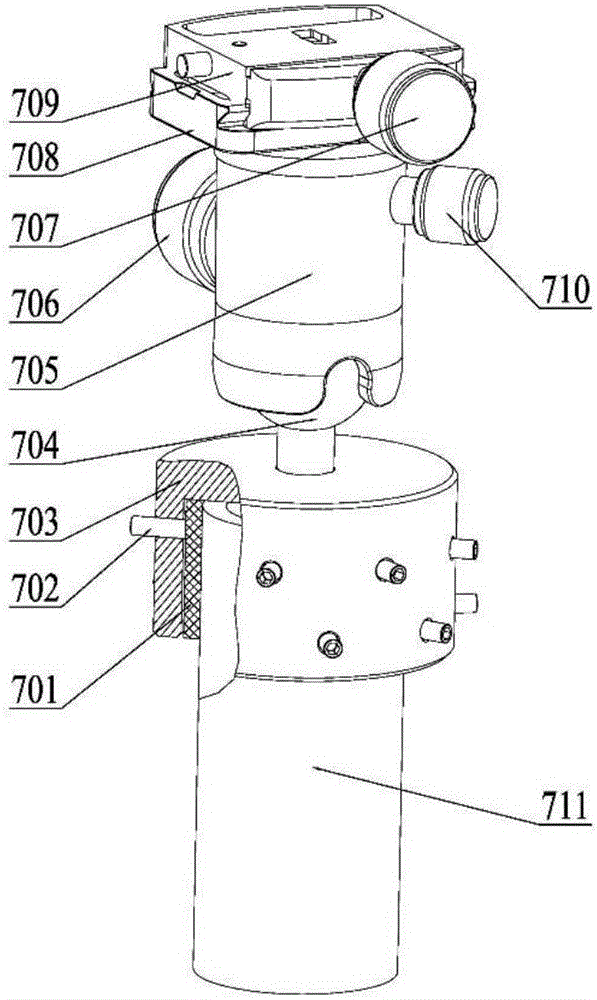

[0079] Such as figure 1 As shown, a cutting machine tool for preparing bone samples includes a motor driver 1, a motor 2, a chassis 3, a coupling 4, a laser collimator 5, a hydraulic cooling system 6, a multi-angle adjustment pan / tilt assembly 7, Lifting column assembly 8, cutting saw blade 9, feed rail assembly 10, residual hopper assembly 11, and drive shaft 12.

[0080] The motor driver 1, the motor 2 and the coupling 4 are packaged in a chassis 3 made of aluminum profiles. At the same time, the chassis 3 is installed with a fan to dissipate the motor, and the residual hopper assembly 11 and the residual hopper assembly are installed by fastening screws A cutting saw blade 9 driven by the transmission shaft 12 is installed above 11 to cut the bone sample 711 clamped on the multi-angle adjustment platform assembly 7. The multi-angle adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com