Composite resin film with good light screen printing effect and preparation method thereof

A composite resin, shallow screen printing technology, applied in synthetic resin layered products, chemical instruments and methods, temperature recording methods, etc. No waste residue, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

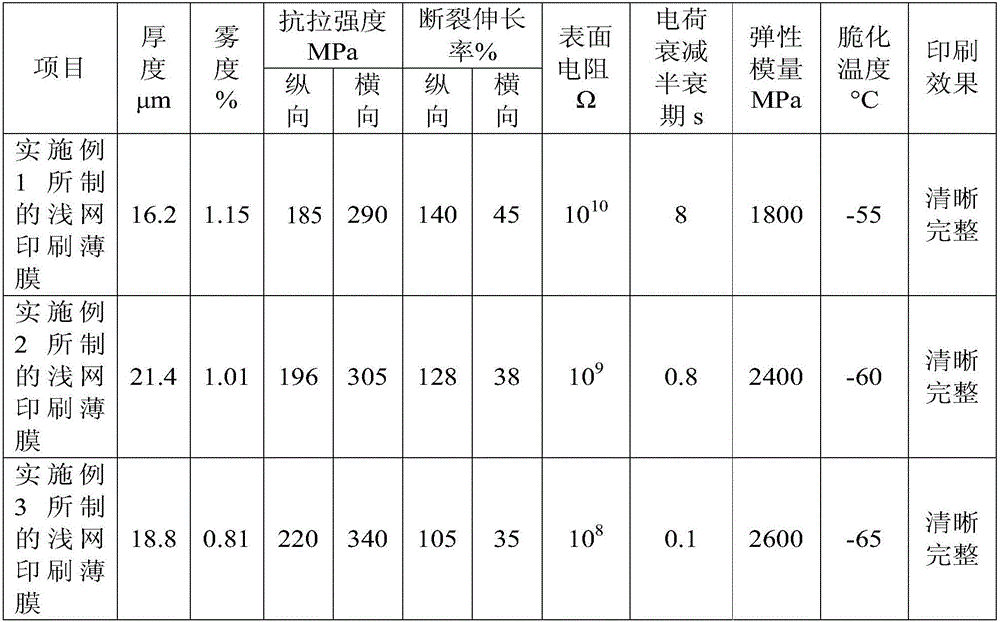

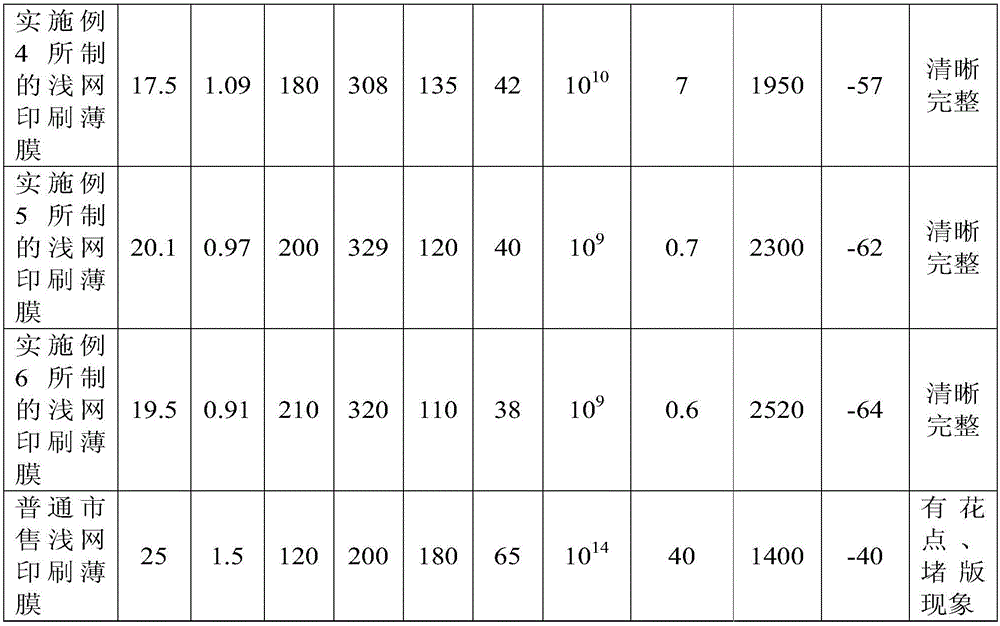

Examples

Embodiment 1

[0029] A composite resin film with good shallow screen printing effect, comprising a three-layer structure of a shallow screen printing layer, a core layer, and a heat-sealing layer;

[0030] The raw materials forming the shallow screen printing layer include 60% isotactic polypropylene, 10% aliphatic polyimide, 10% polyurethane, 10% polyarylsulfone and 10% polycaprolactam in weight percentage. The thickness of the shallow screen printing layer is: 0.1 μm.

[0031] Wherein the raw materials forming the core layer include by weight percentage: isotactic polypropylene 65%, polyphenylene ether 10%, polyethylene naphthalate 15%, sodium lauryl polyoxyethylene ether sulfate 6% , Tetradecyltrimethylammonium bromide 4%. The thickness of the core layer is: 16 μm.

[0032] The raw materials forming the heat-sealing layer include by weight percentage: 40% polycarbonate, 30% amino resin, 15% polyhydroxybutyrate-valerate, 10% polyvinyl chloride, phthalimide 2%, bistrifluoromethanesulfon...

Embodiment 2

[0035] A composite resin film with good shallow screen printing effect, comprising a three-layer structure of a shallow screen printing layer, a core layer, and a heat-sealing layer;

[0036] The raw materials forming the shallow screen printing layer include 80% isotactic polypropylene, 5% aliphatic polyimide, 5% polyurethane, 5% polyarylsulfone and 5% polycaprolactam in weight percentage. The thickness of the shallow screen printing layer is: 0.7 μm.

[0037] Wherein the raw materials forming the core layer include by weight percentage: 85% isotactic polypropylene, 5% polyphenylene ether, 8% polyethylene naphthalate, 1% tetradecyl sulfopropyl betaine, Sodium dodecylbenzenesulfonate 1%. The thickness of the core layer is: 20 μm.

[0038] Wherein the raw materials forming the heat-sealing layer include by weight percentage: polycarbonate 60%, amino resin 20%, polyhydroxybutyrate-valerate 10%, polyvinyl chloride 8%, methylene succinic anhydride 0.5% %, adipic anhydride 1.5%....

Embodiment 3

[0041] A composite resin film with good shallow screen printing effect, comprising a three-layer structure of a shallow screen printing layer, a core layer, and a heat-sealing layer;

[0042] The raw materials forming the shallow screen printing layer include 70% isotactic polypropylene, 7% aliphatic polyimide, 8% polyurethane, 7% polyarylsulfone and 8% polycaprolactam in weight percentage. The thickness of the shallow screen printing layer is: 0.4 μm.

[0043] The raw materials forming the core layer include 75% of isotactic polypropylene, 8% of polyphenylene ether, 11% of polyethylene naphthalate, and 6% of tetradecyl sulfopropyl betaine by weight percentage. The thickness of the core layer is: 18 μm.

[0044] The raw materials forming the heat-sealing layer include by weight percentage: 50% polycarbonate, 25% amino resin, 13% polyhydroxybutyrate-valerate, 8% polyvinyl chloride, phthalimide 4%. The thickness of the heat-sealing layer is: 0.4 μm.

[0045] The proportions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com