Electric car heat management device

An electric vehicle and thermal management technology, applied in electric vehicles, electric power units, power units, etc., can solve problems such as inability to change the control mode, low energy utilization rate of thermal management systems, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

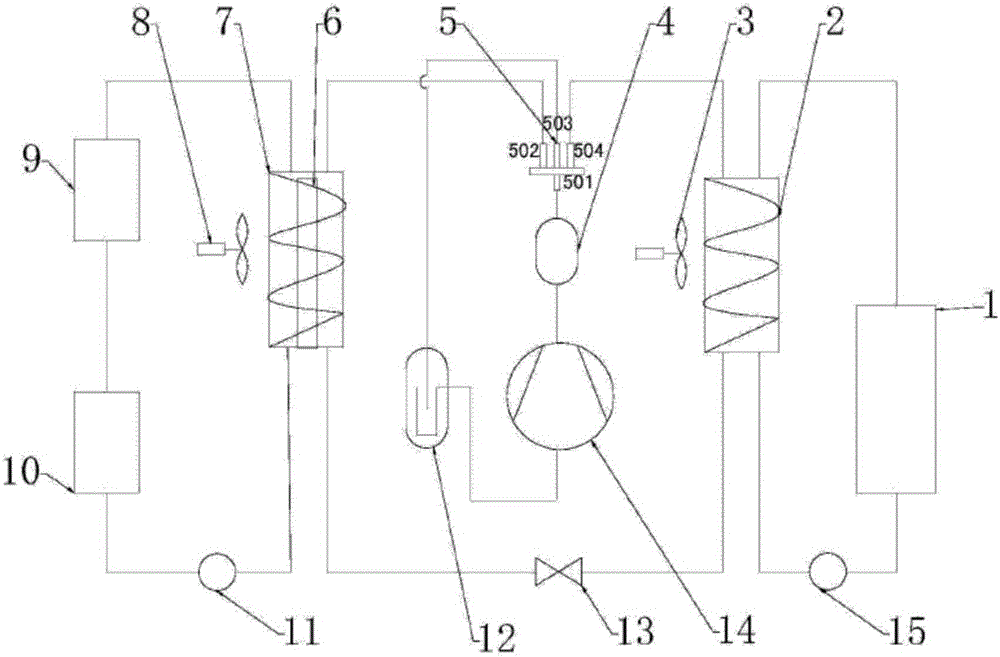

[0022] A heat management device for an electric vehicle, comprising a battery pack cooling jacket 1, a cabin heat exchanger 2, a second air-cooled radiator 3, an oil separator 4, an electromagnetic reversing valve 5, an electric heater 6, and a shell-and-tube heat exchanger Heater 7, first air-cooled radiator 8, motor cooling jacket 9, controller cooling jacket 10, first liquid pump 11, liquid collector 12, thermostat 13, air compressor 14, second liquid pump 15, wherein the electromagnetic reversing valve 5 includes a first port 501, a second port 502, a third port 503, and a fourth port 504. The outlet port of the air compressor 14 communicates with the inlet port of the oil separator 4, and the oil separator The outlet end of 4 communicates with the first port 501 of the electromagnetic reversing valve 5, and the second port 502, the third port 503, and the fourth port 504 of the electromagnetic reversing valve 5 are connected with the shell-and-tube heat exchanger 7 and the...

Embodiment 2

[0029] A heat management device for an electric vehicle, comprising a battery pack cooling jacket 1, a cabin heat exchanger 2, a second air-cooled radiator 3, an oil separator 4, an electromagnetic reversing valve 5, an electric heater 6, and a shell-and-tube heat exchanger Heater 7, first air-cooled radiator 8, motor cooling jacket 9, controller cooling jacket 10, first liquid pump 11, liquid collector 12, thermostat 13, air compressor 14, second liquid pump 15, wherein the electromagnetic reversing valve 5 includes a first port 501, a second port 502, a third port 503, and a fourth port 504. The outlet port of the air compressor 14 communicates with the inlet port of the oil separator 4, and the oil separator The outlet end of 4 communicates with the first port 501 of the electromagnetic reversing valve 5, and the second port 502, the third port 503, and the fourth port 504 of the electromagnetic reversing valve 5 are connected with the shell-and-tube heat exchanger 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com