Metal sulfide-coated single-walled carbon nanotube cable and synthetic method thereof

A single-walled carbon nanotube, metal sulfide technology, applied in the direction of zinc sulfide, nanotechnology, nanotechnology, etc., can solve the problems of affecting the intrinsic properties, limited structure, introduction of defects in single-walled carbon nanotubes, etc., to achieve controllable The effect of strong performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

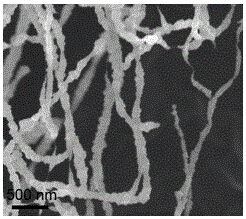

[0019] The mixed powder of graphite, 5.0 wt.% catalyst, 2.0 wt.% growth promoter and 0.2 wt.% zinc powder is pressed into a circular tablet, placed in a porcelain boat, and placed in the central constant temperature zone of the chemical vapor deposition furnace . Argon was used as the protective atmosphere and carrier gas with a flow rate of 50 ml / min. The temperature was raised to 1000°C at a rate of 10°C / min, kept for 1 h, and then cooled naturally. The characterization results of the obtained product are as follows figure 1 shown. The length of the nano-cables grown under this preparation condition is several to tens of microns, the diameter is about 120 nm, the number of single-walled carbon nanotubes in the cable core is between 1-5, the outer shell of the cable is continuous, and the cable The outer cladding layer is polycrystalline zinc sulfide.

Embodiment 2

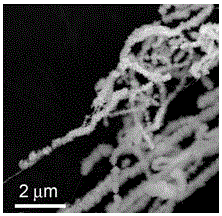

[0021] The mixed powder of graphite, 10.0 wt.% catalyst, 4.0 wt.% growth promoter, 1.0 wt.% silicon powder and 1.0 wt.% zinc powder was pressed into a circular tablet, placed in a porcelain boat, placed The central constant temperature zone of the chemical vapor deposition furnace. Helium was used as the protective atmosphere and carrier gas with a flow rate of 100 ml / min. The temperature was raised to 900°C at a rate of 10°C / min, kept for 0.5 h, and then cooled naturally. The characterization results of the obtained product are as follows figure 2 shown. The length of nanocables grown under this preparation condition is several to tens of microns, and the diameter is about 200 nm. Composed of nanocrystalline grains, the outer coating of the cable is polycrystalline zinc sulfide.

Embodiment 3

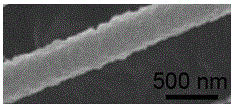

[0023] The mixed powder of graphite, 20.0 wt.% catalyst, 8.0 at.% growth promoter, 2.0 wt.% silicon powder and 2.0 wt.% zinc oxide powder was pressed into a circular tablet, placed in a porcelain boat, and placed In the central constant temperature zone of the chemical vapor deposition furnace. Nitrogen was used as the protective atmosphere and carrier gas, and the flow rate was 120 ml / min. The temperature was raised to 1000°C at a rate of 10°C / min, kept for 1.2 h, and then cooled naturally. The characterization results of the obtained product are as follows image 3 shown. The length of the nano-cable grown under this preparation condition is tens of microns, the diameter is about 400 nm, the number of single-walled carbon nanotubes in the core of the cable is between 1-5, the outer layer of the cable is continuous, and the outer layer of the cable is The cladding is polycrystalline zinc sulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com