Benzoxazine resin based carbon aerogel and a preparing method thereof

A benzoxazine and carbon aerogel technology, which is applied in the field of porous carbon material preparation, can solve the problems of low product purity, high production cost and long preparation period, and achieves high specific surface area, reduced production cost and shortened preparation period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

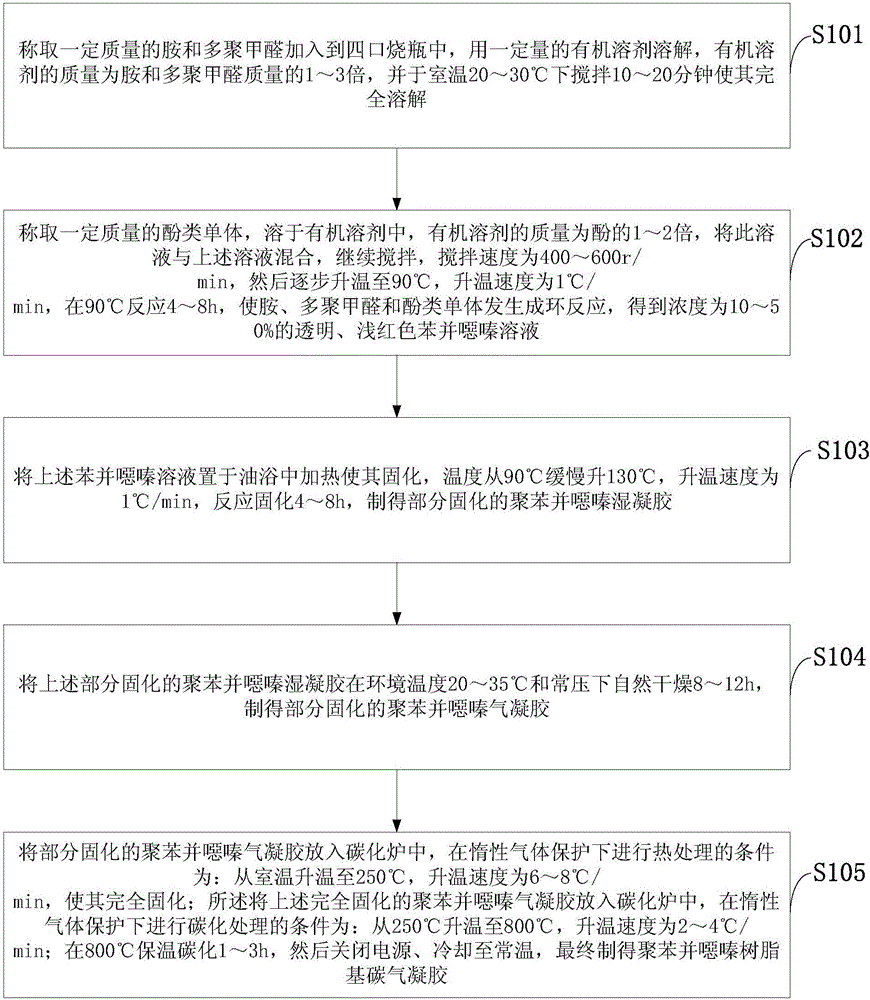

[0054] Such as figure 1 As shown, the preparation method of the benzoxazine resin-based carbon aerogel of the embodiment of the present invention comprises the following steps:

[0055] S101: Weigh a certain amount of amine and paraformaldehyde into a four-necked flask, dissolve it with a certain amount of organic solvent, the mass of the organic solvent is 1 to 3 times the mass of the amine and paraformaldehyde, and put it at room temperature for 20 to 30 Stir at ℃ for 10-20 minutes to dissolve completely;

[0056] S102: Weigh a certain mass of phenolic monomer and dissolve it in an organic solvent whose mass is 1 to 2 times that of phenol, mix this solution with the above solution, and continue to stir at a stirring speed of 400 to 600r / min. Then gradually raise the temperature to 90°C, the heating rate is 1°C / min, and react at 90°C for 4-8 hours, so that the amine, paraformaldehyde and phenolic monomers undergo a ring-forming reaction to obtain a transparent, shallow red ...

Embodiment 1

[0067] Weigh 50g of 4,4'-methylene dianiline, add 30g of paraformaldehyde into a four-neck flask, dissolve with 250ml of xylene, and stir at room temperature 25°C for 20 minutes to completely dissolve;

[0068] Weigh 47.1g of phenol, dissolve it in 50ml of xylene, mix this solution with the above solution, continue to stir at a stirring speed of 400r / min, and gradually raise the temperature to 90°C at a heating rate of 1°C / min. React for 6 hours to prepare a benzoxazine solution with a concentration of 30%; place the above benzoxazine solution in an oil bath at 130°C and heat it for 6 hours to solidify to obtain a partially cured polybenzoxazine wet gel ;

[0069] The above polybenzoxazine wet gel was naturally dried at an ambient temperature of 25°C and normal pressure for 10 hours to obtain a partially cured polybenzoxazine airgel;

[0070] The conditions for placing the partially cured polybenzoxazine airgel in a carbonization furnace and performing heat treatment under th...

Embodiment 2

[0074] Weigh 75g of 4,4'-methylene dianiline, add 45g of paraformaldehyde into a four-neck flask, dissolve with 150ml of xylene, and stir at room temperature 25°C for 20 minutes to completely dissolve;

[0075] Weigh 70.7g of phenol and dissolve it in 50ml of xylene. After dissolving, add this solution to the above solution and stir at a stirring speed of 600r / min. The reaction was carried out for 8 hours to obtain a 50% benzoxazine solution;

[0076] The above benzoxazine solution was placed in an oil bath at 130°C and heated for 8 hours to solidify to obtain a partially cured polybenzoxazine wet gel;

[0077] The above polybenzoxazine wet gel was naturally dried at an ambient temperature of 25°C and normal pressure for 12 hours to obtain a partially cured polybenzoxazine airgel;

[0078] The conditions for placing the partially cured polybenzoxazine airgel in a carbonization furnace and performing heat treatment under the protection of an inert gas are as follows: from room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com