Hollow molecular sieve, and preparation method and application thereof

A molecular sieve and hollow technology, applied in the field of molecular sieves, can solve problems such as limiting the practical application of molecular sieves, achieve the effects of solving diffusion problems, low preparation costs, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of ZSM-5 type hollow molecular sieve comprises the steps:

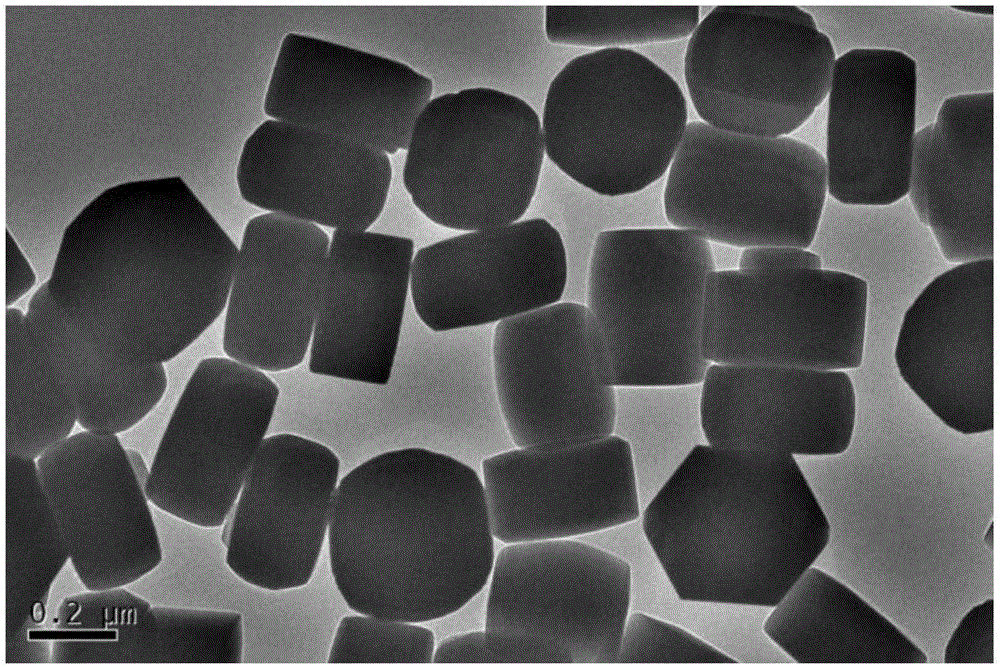

[0031] 1) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O was mixed at a molar ratio of 1:0.1:0:20, stirred thoroughly, and hydrothermally crystallized; the product was centrifuged and washed to obtain a gel containing ZSM-5, which was used as a seed crystal for future use. The structure of the seed crystal was as follows: figure 1 shown;

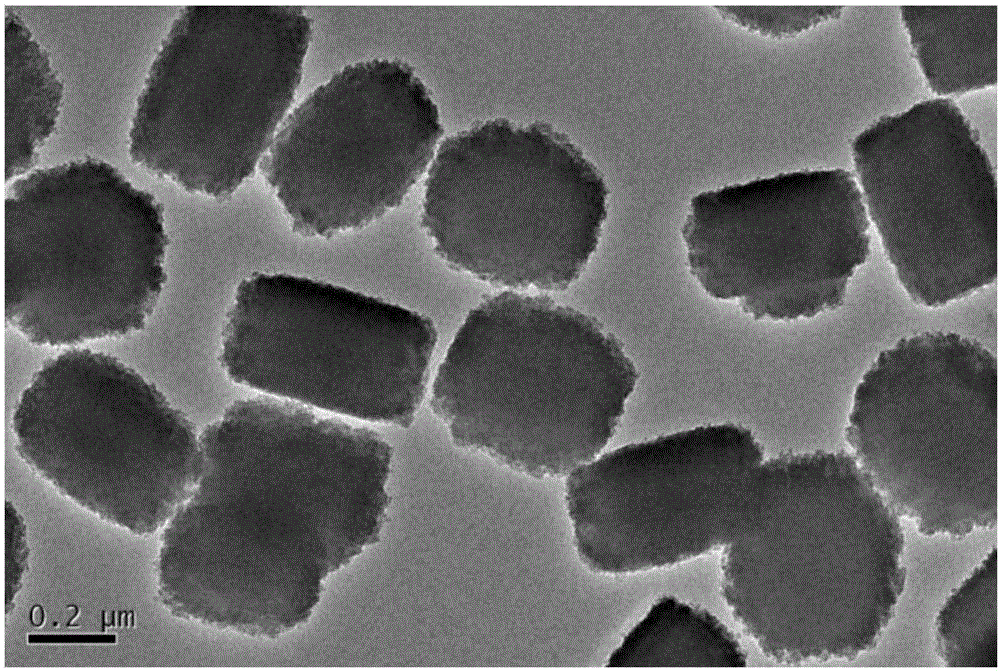

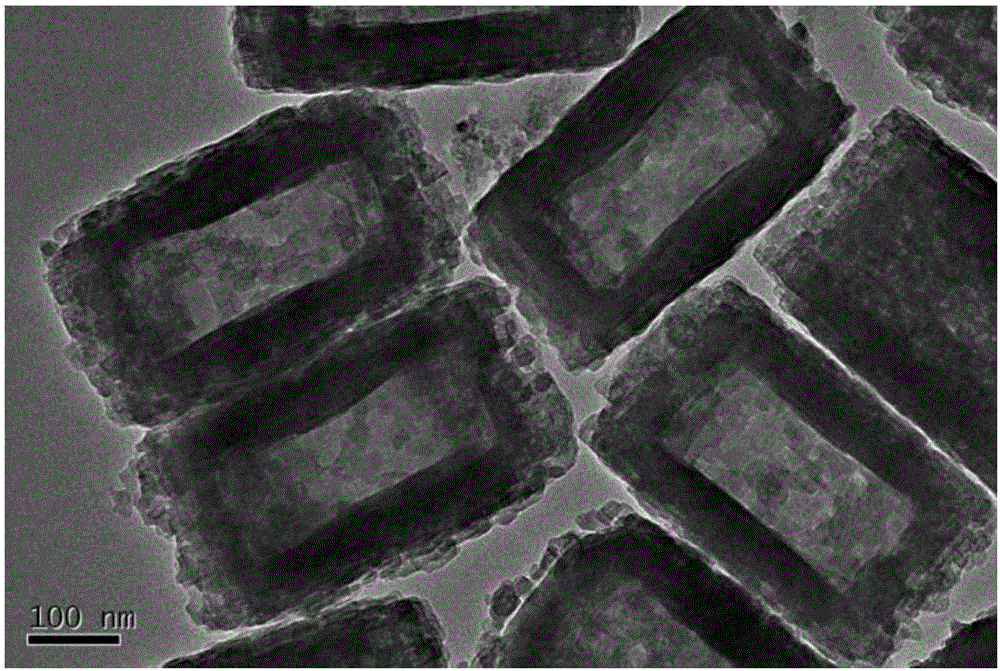

[0032] 2) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O is mixed at a molar ratio of 1:1:0.125:600, and after being fully stirred, a ZSM-5 growth solution is obtained; then the seed crystal prepared in step 1) is added to the ZSM-5 growth solution, and the seed crystal and the ZSM-5 molecular sieve grow The mass ratio of the solution is 1:200, hydrothermal crystallization; the crystallized product is centrifuged, washed, dried, and roasted to obtain a ZSM-5 molecular sieve whos...

Embodiment 2

[0036] The preparation method of ZSM-5 type hollow molecular sieve comprises the steps:

[0037] 1) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O was mixed at a molar ratio of 1:0.5:0.125:100, stirred thoroughly, hydrothermally crystallized; the product was centrifuged and washed to obtain a gel containing ZSM-5, which was used as a seed crystal for later use;

[0038] 2) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O is mixed in a molar ratio of 1:0.25:0:200, and after fully stirring, a ZSM-5 growth solution is obtained; then the seed crystal prepared in step 1) is added to the ZSM-5 growth solution, the seed crystal and the ZSM-5 molecular sieve growth solution The mass ratio is 1:50, hydrothermal crystallization; the crystallized product is centrifuged, washed, dried, and roasted to obtain a ZSM-5 molecular sieve whose core-shell is composed of different Si / Al ratio structures;

[0039] 3) Add the ...

Embodiment 3

[0042] The preparation method of ZSM-5 type hollow molecular sieve comprises the steps:

[0043] 1) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O was mixed at a molar ratio of 1:0.2:0.04:50, stirred thoroughly, and hydrothermally crystallized; the product was centrifuged and washed to obtain a gel containing ZSM-5, which was used as a seed crystal for later use;

[0044] 2) Ethyl orthosilicate, tetrapropylammonium hydroxide, Al(NO 3 ) 3 9H 2 O and H 2 O is mixed with a molar ratio of 1:0.8:0.08:500, and after being fully stirred, a ZSM-5 growth solution is obtained; then the seed crystal prepared in step 1) is added to the ZSM-5 growth solution, the seed crystal and the ZSM-5 molecular sieve growth solution The mass ratio is 1:100, hydrothermal crystallization; the crystallized product is centrifuged, washed, dried, and roasted to obtain a ZSM-5 molecular sieve whose core-shell is composed of different Si / Al ratio structures;

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com