Method for preparing independent self-supporting transparent aluminium nitride nanocrystalline film

An aluminum nitride, self-supporting technology, applied in nanotechnology, gaseous chemical plating, metal material coating process, etc., to achieve the effects of low cost, simple growth method and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

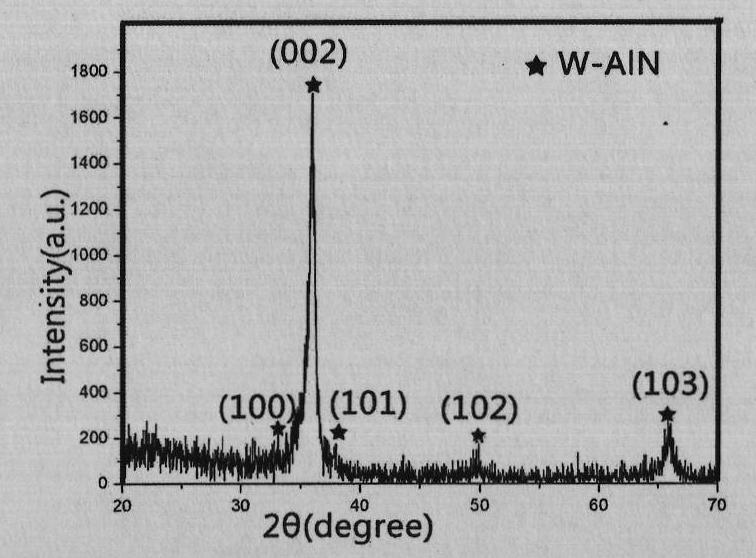

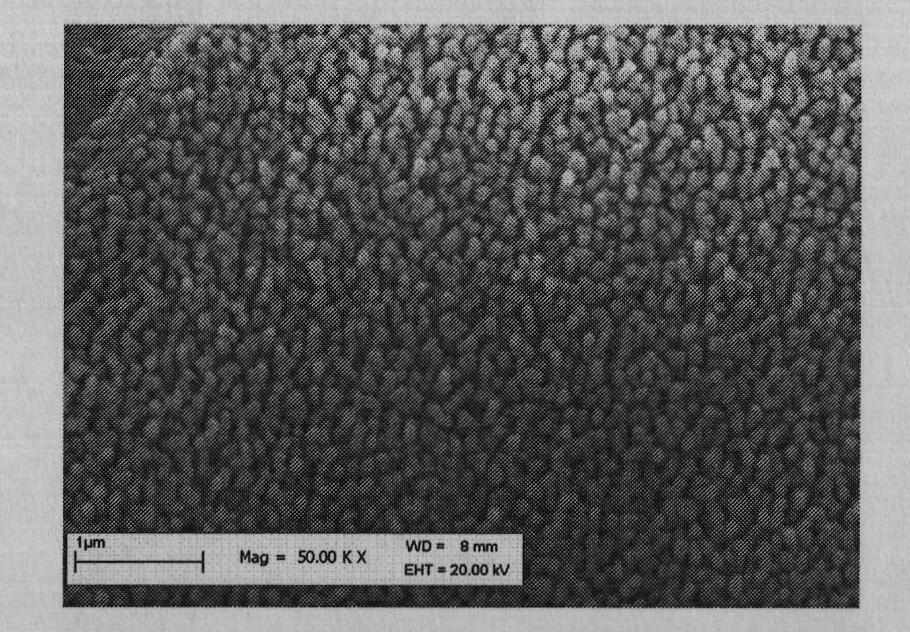

Embodiment 1

[0021] A certain amount of anhydrous AlCl 3 (Purity is 99% by mass) The ceramic boat of powder is placed on the upper free nozzle 6cm place of horizontal tube furnace, places ceramic sheet and quartz sheet as the collection substrate of product at 25cm away from ceramic boat, airtight horizontal tube furnace Then evacuate to 2×10 -2 Pa, heat the tube furnace to 850°C in an Ar atmosphere, stop feeding Ar, and feed 200 sccm of NH 3 gas reaction for 4 hours, and finally cooled naturally to room temperature under Ar atmosphere, and an independent self-supporting transparent film product that can be detached from the substrate was obtained on the collection substrate. The XRD pattern analysis results of the resulting product show that it is a wurtzite structure aluminum nitride that grows preferentially along the (002) direction, such as figure 1 shown. Its scanning electron micrograph shows that the microstructure of the obtained product is a nanocrystal array, such as figure...

Embodiment 2

[0023] Will contain a certain amount of anhydrous AlCl 3 (Purity is 99% by mass) The ceramic boat of powder is placed on the horizontal tube furnace upper free nozzle 6cm place, a plurality of small quartz tubes (diameter is 2cm, long about 10cm) are placed in parallel at the lower free ceramic boat 20cm place as product collection device, the closed tube furnace is evacuated to 2×10 -2 Pa, heat the tube furnace to 900°C in an Ar atmosphere, stop feeding Ar, and feed 250 sccm of NH 3 Gas, reacted for 4 hours, and finally cooled naturally to room temperature under Ar atmosphere, and a large number of independent self-supporting transparent aluminum nitride films were obtained in the downstream quartz tube.

Embodiment 3

[0025] Will contain a certain amount of anhydrous AlCl 3 (Purity is mass percentage 99%) the ceramic boat of powder is placed on the upper free nozzle 6cm place of horizontal tube furnace, place graphite paper as product collector at 25cm place away from ceramic boat, airtight horizontal tube furnace is then evacuated to 2 ×10 -2 Pa, heat the tube furnace to 850°C in an Ar atmosphere, and feed 200 sccm of NH 3 Gas and the Ar flow rate was adjusted to 50 sccm, reacted for 4 hours, and finally cooled naturally to room temperature in an Ar atmosphere, and a large number of self-supporting transparent aluminum nitride films were collected on graphite paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com