Preparation and construction technology of grout sealant slurry

A grout sealant slurry and manufacturing process technology, which is applied to roads, on-site paved condensate pavements, buildings, etc., can solve the problems of high noise at micro-surfaces, insufficient road surface aesthetics, poor durability of fog seals, etc. , achieve excellent cost performance, convenient construction, and improve weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

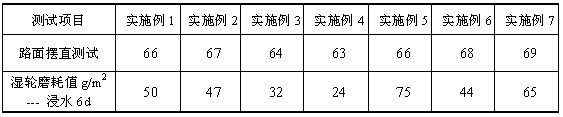

Examples

Embodiment 1

[0025] Embodiment 1 The preparation process of grout sealant slurry comprises the following steps:

[0026] (1) Dry mix carbon black and non-expandable sodium bentonite at a ratio of 2kg:99kg, and mix evenly to obtain P material.

[0027] (2) Mix material P, latex, and water at a ratio of 100 kg: 40 kg: 100 kg, and use paddle stirring or turbine stirring at a stirring speed of 20-80 rpm to obtain material J.

[0028] (3) Stir and mix J material with emulsified asphalt, fine aggregate, and silica sol at the ratio of 225 kg: 160 kg: 500 kg: 125 kg to obtain grout seal layer slurry.

[0029] The construction process of the grout seal layer slurry obtained by the grout seal layer slurry production process refers to: the grout seal layer slurry is sprayed by a pressurized spraying device with a nozzle diameter greater than 3mm and a pressure of 1.25MPa, or Carry out manual scraping construction directly according to the conventional method.

Embodiment 2

[0030] Embodiment 2 The preparation process of grout sealant slurry comprises the following steps:

[0031] (1) Dry mix carbon black and non-expandable sodium bentonite at a ratio of 3kg:99kg, and mix evenly to obtain P material.

[0032] (2) Mix material P, latex, and water at a ratio of 100 kg: 50 kg: 100 kg, and use paddle stirring or turbine stirring at a stirring speed of 20-80 rpm to obtain material J.

[0033] (3) Stir and mix J material with emulsified asphalt, fine aggregate, and silica sol at a ratio of 225 kg: 170 kg: 600 kg: 125 kg to obtain grout seal layer slurry.

[0034] The construction process of the grout seal layer slurry obtained by the grout seal layer slurry preparation process is the same as that in Example 1.

Embodiment 3

[0035] Embodiment 3 The preparation process of grout sealant slurry comprises the following steps:

[0036] (1) Dry mix carbon black and non-expandable sodium bentonite at a ratio of 2kg:99kg, and mix evenly to obtain P material.

[0037] (2) Mix material P, latex, and water at a ratio of 100 kg: 40 kg: 100 kg, and use paddle stirring or turbine stirring at a stirring speed of 20-80 rpm to obtain material J.

[0038] (3) Stir and mix J material with emulsified asphalt, fine aggregate, and silica sol at a ratio of 225 kg: 180 kg: 700 kg: 125 kg to obtain grout seal layer slurry.

[0039] The construction process of the grout seal layer slurry obtained by the grout seal layer slurry preparation process is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com