Preparation method of fertilizer containing microorganisms

A technology of microorganisms and microbial agents, applied in the preparation of organic fertilizers, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of inability to exert the effect of microbial agents, the death of "indigenous" microorganisms, and the inability to form population effects, etc. problems, to achieve the effect of improving crop quality, strong survival competitiveness, and strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

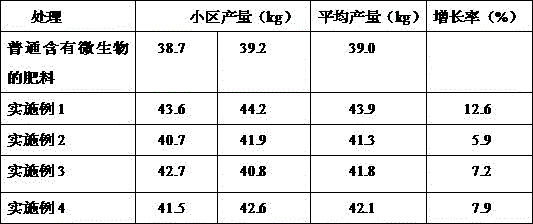

Embodiment 1

[0036] Add kelp, soybean meal, wheat bran, slaked lime and distilled water into a fermenter at a mass ratio of 200:500:300:1:350 and sterilize at 120°C for 20 minutes to obtain product A. And prepare the fermented seed liquid: inoculate the Lactobacillus acidophilus into the liquid medium at 30° C., and cultivate for 26 hours. The liquid medium is: beef extract 3g, peptone 4g, soluble starch 8g, potassium nitrate 0.8g, potassium dihydrogen phosphate 0.3g, magnesium sulfate 0.6g, ferrous sulfate 0.01g, sodium chloride 1g, agar 15g, distilled water 1000ml, pH6.8, the ratio of Lactobacillus acidophilus and liquid medium is 8:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 8:100, and anaerobically ferment for 8 days at 30°C and pH 6.5 to 7.5 to obtain product B; adjust the pH of product B to 4.5-5, cool the temperature of the fermenter to 4°C, store for 4 days, return the temperature to 30°C to obtain product C; add the seed liquid to ...

Embodiment 2

[0038] Add kelp, soybean meal, wheat bran, slaked lime and distilled water into a fermenter at a mass ratio of 200:500:300:2:250 and sterilize at 120°C for 25 minutes to obtain product A. And prepare the fermented seed liquid: inoculate the Lactobacillus acidophilus into the liquid medium at 25° C., and cultivate for 30 hours. The liquid medium is: beef extract 3g, peptone 4g, soluble starch 8g, potassium nitrate 0.8g, potassium dihydrogen phosphate 0.3g, magnesium sulfate 0.6g, ferrous sulfate 0.01g, sodium chloride 1g, agar 15g, distilled water 1000ml, pH6.8; the ratio of Lactobacillus acidophilus to liquid medium is 8:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 8:100, and anaerobically ferment for 6 days at 25°C and pH 6.0 to 7.0 to obtain product B; adjust the pH of product B to 4.5~5, cool the temperature of the fermenter to 2°C, store for 3 days, return the temperature to 25°C to obtain product C; add the seed liquid to t...

Embodiment 3

[0040]Add kelp, soybean meal, wheat bran, citric acid and distilled water in a mass ratio of 200:500:300:1:500 into a fermenter and sterilize at 110°C for 30 minutes to obtain product A. And prepare the fermented seed liquid: inoculate the Lactobacillus acidophilus into the liquid medium at 35° C., and cultivate for 24 hours. The liquid medium is: beef extract 3g, peptone 4g, soluble starch 8g, potassium nitrate 0.8g, potassium dihydrogen phosphate 0.3g, magnesium sulfate 0.6g, ferrous sulfate 0.01g, sodium chloride 1g, agar 15g, distilled water 1000ml, pH6.8; the ratio of Lactobacillus acidophilus to liquid medium is 8:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 8:100, and anaerobically ferment for 9 days at 35°C and pH5.5-6.5 to obtain product B; adjust the pH of product B to 4.5-5, cool the temperature of the fermenter to 8°C, store for 5 days, return the temperature to 35°C to obtain product C; add the seed liquid to produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com