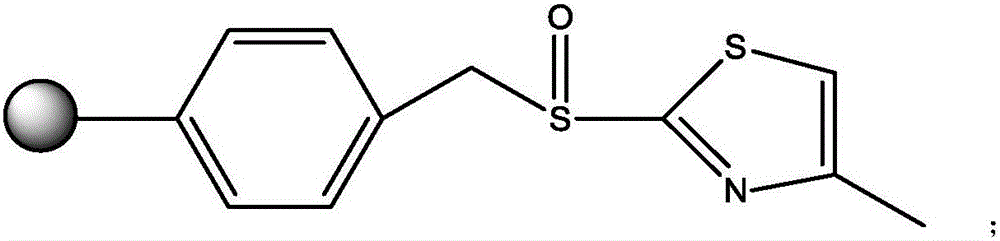

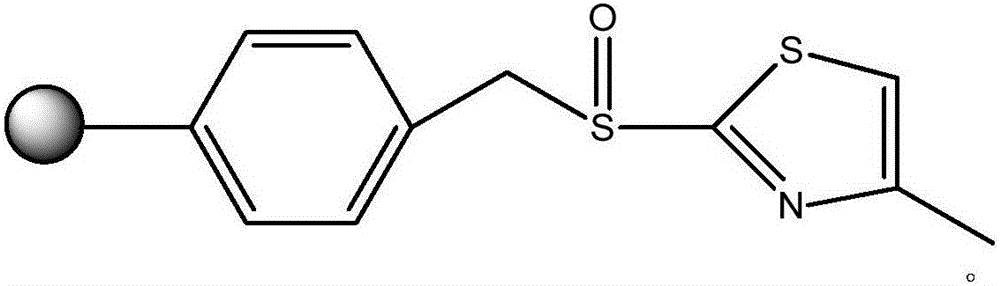

Method for separating iridium and platinum through polystyrene-4-methylthiazole sulfoxide resin

A technology of methylthiazole sulfoxide and polystyrene, which is applied in the field of separating iridium and platinum with polystyrene-4-methylthiazole sulfoxide resin, and can solve the problems of lack of industrial scale application, great environmental hazards, poor selectivity, etc. problems, to achieve the effect of low cost, low equipment corrosion and high separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take by weighing 2.0g resin as stationary phase, add C (HCl) to be 0.5mol / L, through K 2 S 2 o 8 In the 100mL Ir(IV) solution with a concentration of 8500mg / L after solution oxidation treatment, shake for 60min, filter out the loaded PS-4-MTS; measure the Ir adsorption, add the filtered out Ir-loaded resin to 40mL 1% NaOH In the solution, shake for 30 minutes, filter out the PS-4-MTS in the desorption solution, wash the PS-4-MTS twice with distilled water, absorb the same Ir(IV) solution again, and measure the static adsorption capacity value for 6 cycles.

[0023] Advantage of the present invention, can find out from above-mentioned experiment, the mensuration result of 6 cycles static adsorption capacity is as shown in table 1:

[0024] Table 1. Determination of cyclic static adsorption capacity

[0025] Cycles

[0026] It can be seen from Table 1 that after 6 cycles of use, the static adsorption capacity of PS-4-MTS for Ir(IV) did not decrease significan...

Embodiment 2

[0028] 1. Weigh 1.0gPS-4-MTS as stationary phase, add to C(HCl) to 0.1mol / L, 2 S 2 o 8 In the 50mL mixed material liquid containing Ir and Pt after the solution was oxidized, the contents of Ir and Pt in the mixed material liquid were 20mg / L and 50mg / L respectively, shaken for 30min, and filtered out the loaded PS-4-MTS; determination of Ir adsorption The amount is 0.99mg / g.Ir and Pt separation coefficient is 4.9×10 4 (see Table 2 for specific data).

[0029] 2. Add the filtered Ir-loaded PS-4-MTS into 20 mL of 0.5% NaOH solution, shake for 20 minutes, and filter out the PS-4-MTS in the desorption solution. Measure the content of Ir in the desorption solution, and calculate the desorption rate (see Table 2 for specific data).

Embodiment 3

[0031] 1. Weigh 2.0g PS-4-MTS as stationary phase, add to C(HCl) to 0.2mol / L, 2 S 2 o 8 In the 100mL mixed material solution containing Ir and Pt after the solution was oxidized, the contents of Ir and Pt in the mixed material solution were 110mg / L and 160mg / L respectively, shaken for 30min, and filtered out the loaded PS-4-MTS; determination of Ir adsorption The amount is 5.45mg / g.Ir and Pt separation coefficient is 1.7×10 4 (see Table 2 for specific data).

[0032] 2. Add the filtered Ir-loaded PS-4-MTS into 40 mL of 0.5% NaOH solution, shake for 25 minutes, and filter out the PS-4-MTS in the desorption solution. Measure the content of Ir in the desorption solution, and calculate the desorption rate (see Table 2 for specific data).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com