Reaming drill bit with long service life for strata difficult to drill

A reaming drill bit and long-life technology, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc., can solve problems such as not being able to enter the well again, cutting teeth are difficult to invade rocks, and the drilling efficiency of the drill bit is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

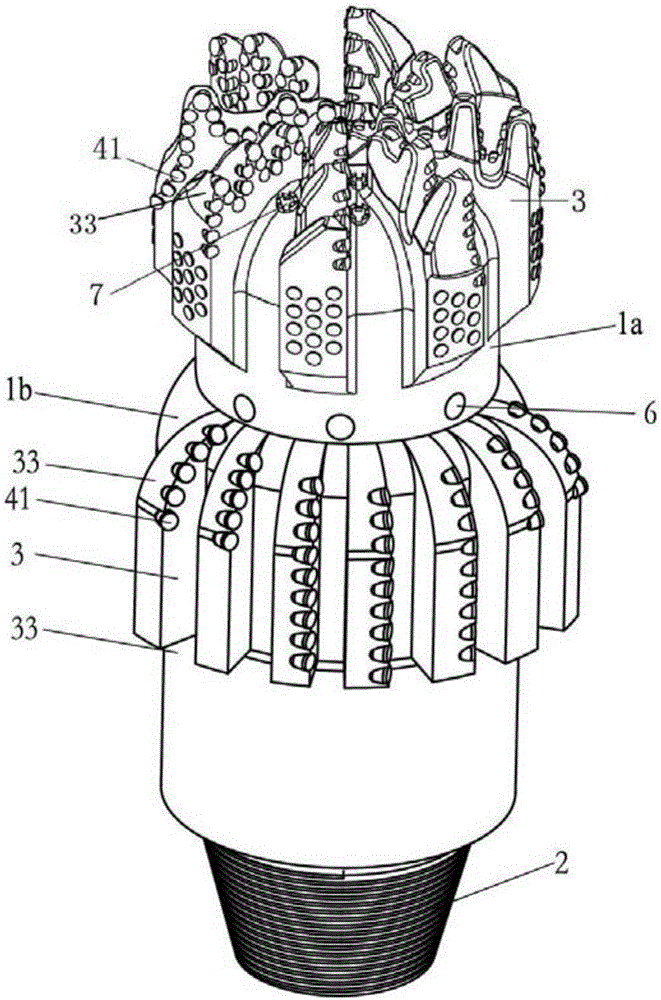

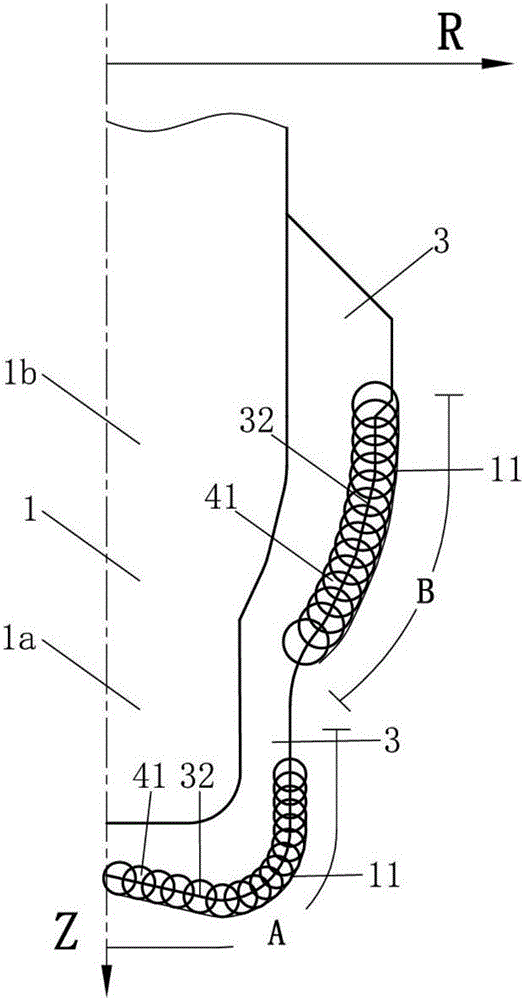

[0109] Such as Figure 1 to Figure 24 As shown, a long-life reaming drill bit for difficult-to-drill formations includes a drill body 1 composed of a pilot body 1a and a reamer body 1b and a plurality of blades 3 extending from the body. The blades 3 are provided with several first A group of cutting teeth 41, the tooth surface 33 of the blade 3 is provided with dimples to fix the first group of cutting teeth 41, water holes 6 or nozzles 7 are arranged in the flow channel between the blades, and at least one pilot section is provided And / or the body outline 32 of the reaming section blade 3 (may include the front blade body outline 32a and the rear blade body outline 32b) and at least one other pilot eye section and / or reaming section blade The body contours 32 of 3 have at least one non-coinciding region, and at least one coincident point or region within the common coverage. The first set of cutting teeth 41 may be polycrystalline diamond composite sheets, polycrystalline d...

Embodiment 2

[0116] Such as Figure 8 As shown, it is a schematic diagram of tooth arrangement of two asynchronous blades on the pilot section of the reaming drill bit in this example. In this embodiment, the two pilot blades 3 cover the entire radial area, and the outline of the body 32 are overall convex curves, and the outlines of the two blades overlap in the core area of the drill bit, but do not overlap in the outer area. The convex apexes 323 of the two blades are staggered in the same axial plane of the drill bit.

Embodiment 3

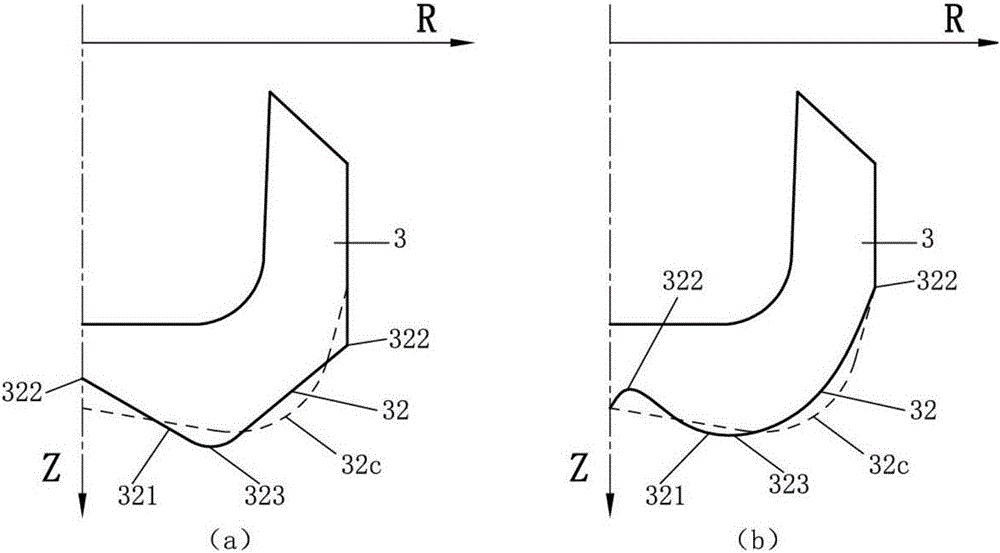

[0118] Such as Figure 9 (a), Figure 9 As shown in (b), it is a schematic diagram of the arrangement of teeth of three pilot segment asynchronous blades on the drill bit of this embodiment. In this embodiment, the body contour lines 32 of the three pilot segment blades 3 are integral For the convex single-peak curve, the coverage area of the convex part 321 is the entire radial area from the center to the edge of the drill bit, and the vertices 323 of the convex parts 321 of different blades 3 are mutually staggered in the same drill bit axial plane. in, Figure 9 The outline of the blade body shown in (a) is a relatively sharp curve in the convex area formed by the connection of straight lines and arcs. Figure 9 The contour line of the blade body shown in (b) is a relatively smooth curve formed by an arc or an approximate arc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com