Gas liquefaction device with compression heat recovery function and liquefaction method thereof

A liquefaction device and heat recovery technology, applied in the field of gas cryogenic liquefaction, can solve the problems of conventional gas liquefaction devices such as high energy consumption, waste of compression heat, consumption of large circulating water, etc., achieve good social and economic benefits, and reduce energy consumption , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

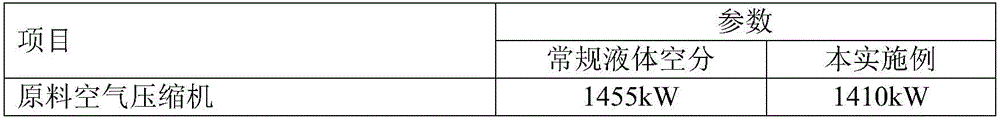

Embodiment 1

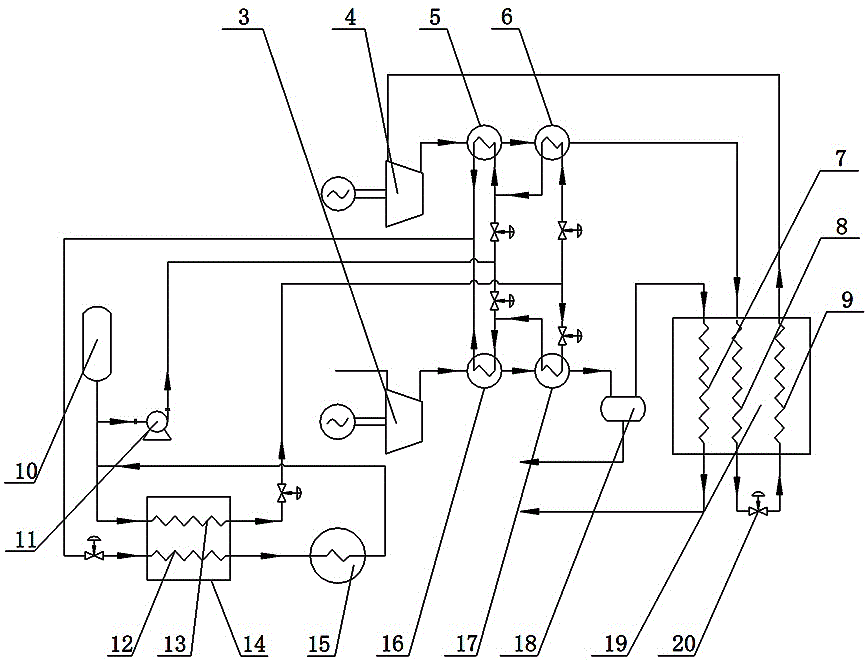

[0042] like figure 1 As shown, a gas liquefaction device with compression heat recovery includes a raw material gas treatment system, a refrigerant treatment system, and a compression heat recovery system;

[0043] In this embodiment, the raw gas treatment system includes a raw gas compressor 3, a raw gas normal temperature water cooler 16, a raw gas low temperature water cooler 17, a raw gas purification unit 18 and a gas liquefaction heat exchanger 19, wherein , the raw material gas input pipeline is connected with the raw material gas compressor 3, the raw material gas compressor 3 is communicated with the raw gas normal temperature water cooler 16, and the raw material compressor 3 is connected with a raw material gas supply pipeline, in the present embodiment, the described The feed gas is one or more of oxygen, nitrogen, hydrogen, natural gas liquefaction or liquid air separation. The feed gas normal temperature water cooler 16 is connected with the feed gas low temperat...

Embodiment 2

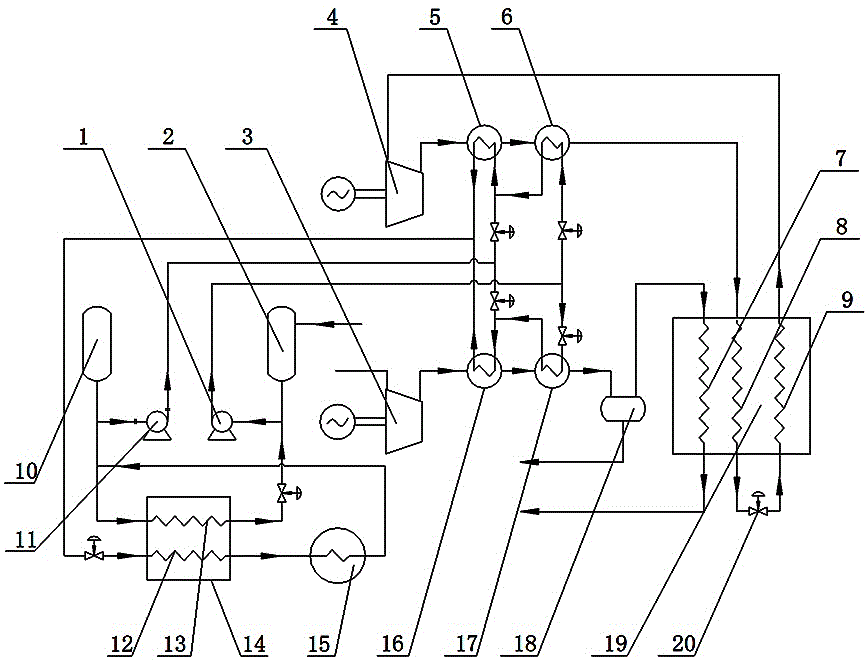

[0064] like figure 2 As shown, the device of this embodiment is substantially the same as that of Embodiment 1, the difference is that a low-temperature pipe is also provided on the pipeline communicating with the water inlet pipe of the refrigerant room temperature water cooler 5 and the raw material gas room temperature water cooler 16 water inlet pipe. The water tank 2 and the low-temperature water pump 1 are on the pipeline, with the low-temperature water delivery direction as the front, the low-temperature water pump 1 is located downstream of the low-temperature water tank 2, and the low-temperature water tank 2 can be replenished with low-temperature water through a low-temperature water supply pipeline , to ensure the continuous supply of low-temperature water, so that the low-temperature water can be continuously sent to the liquefaction device, and can also be sent during peak or peak electricity prices, and low-temperature water can also be taken by a compression re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com