Split type gas laser leak detection device

A gas laser, split technology, applied in the field of laser applications, can solve the problems of small use range, bulky, inflexible operation, etc., achieve accurate positioning, uniform distribution, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

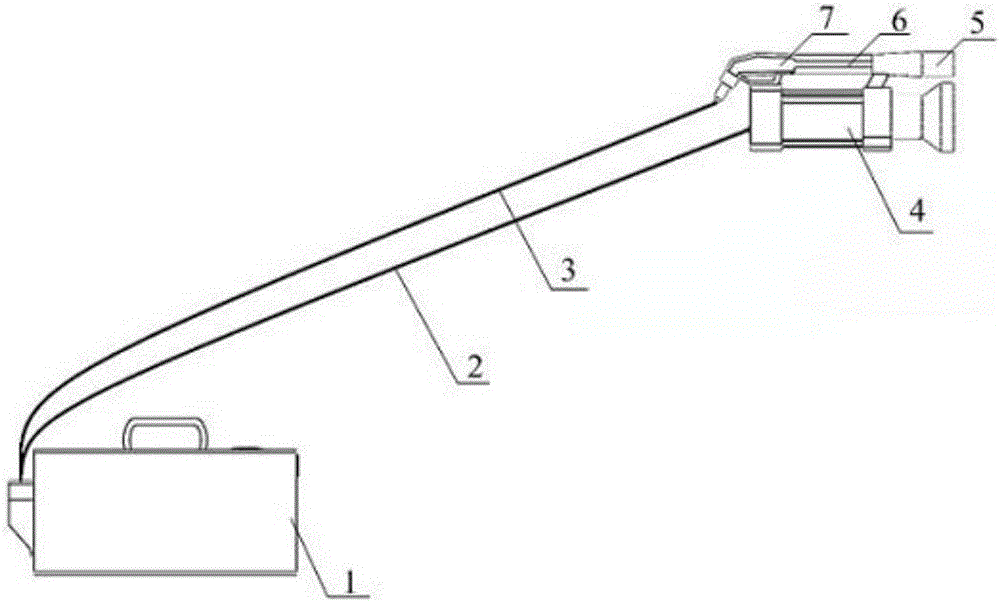

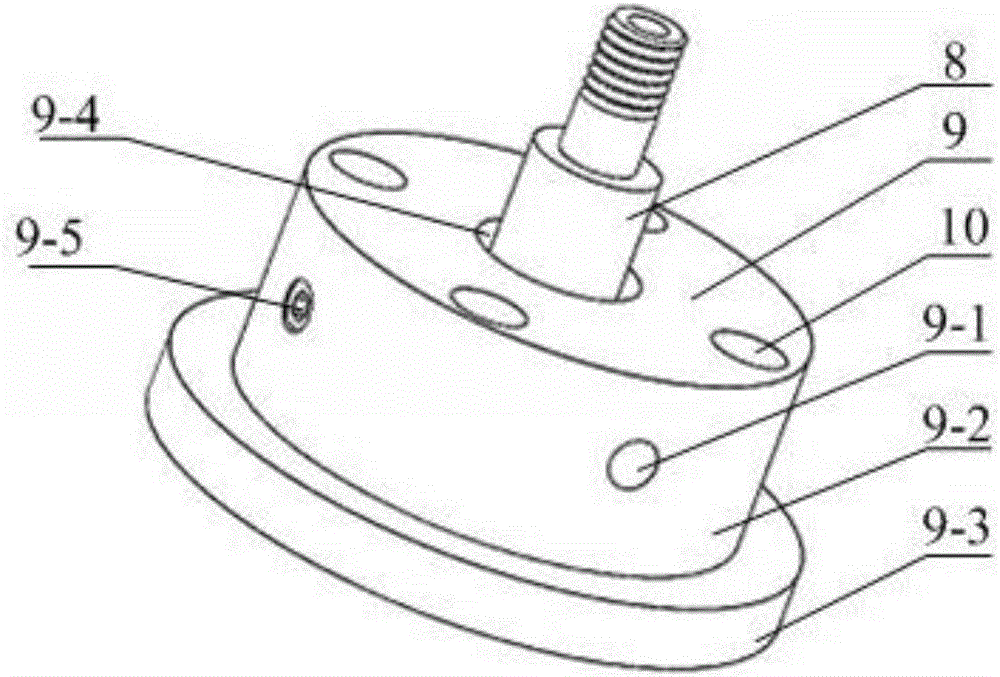

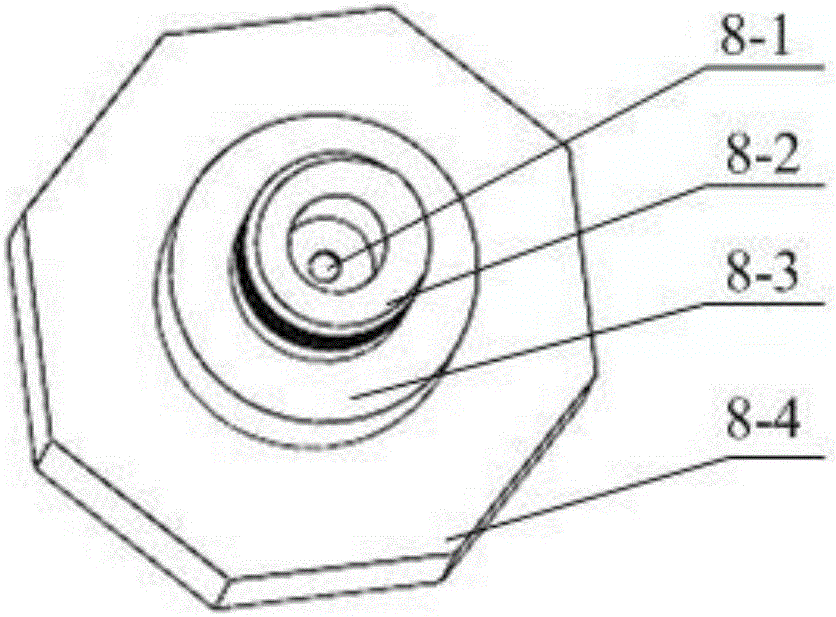

[0028] The invention provides a split type gas laser leak detection device, such as figure 1 As shown, it includes a power control box 1 and a laser leak detector 7. Optical equipment is arranged in the power control box 1, and the optical equipment includes a laser generator; the laser leak detector 7 includes a laser homogenizer 11 and a rotatable refractor 5 , the laser homogenizer 11 is connected with the refractor 7 through the lens barrel 6, and the infrared camera 4 for taking pictures and videos is arranged under the lens barrel 6; the power control box 1 is connected with the laser leak detector through the power control line 2 and the signal line 3 7 connections.

[0029] The split-type gas laser leak detection device of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com