A kind of three-dimensional structure gain compensation type saw device and its preparation method

A technology of gain compensation and three-dimensional structure, applied in the direction of electrical components, impedance networks, etc., can solve the problems of heavy consistency and large time-line insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a three-dimensional structure gain-compensated SAW device, comprising:

[0032] Step 1. Fabricate LNA on silicon substrate by IC process;

[0033] Step 2, making a piezoelectric film on the surface of the silicon substrate with the LNA;

[0034] Step 3, preparing a layer of metal aluminum film or copper film by evaporation or sputtering on the surface of the substrate with LNA and piezoelectric film;

[0035] Step 4. Etching the mask pattern of the interdigital transducer (IDT) on the surface of the metal aluminum film or copper film by photolithography;

[0036] Step 5, encapsulating, encapsulating it in an insulating casing.

Embodiment 1

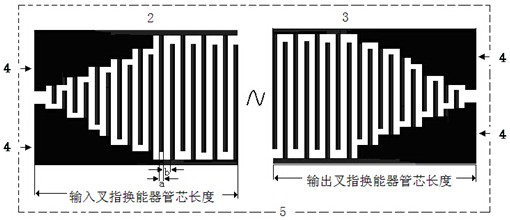

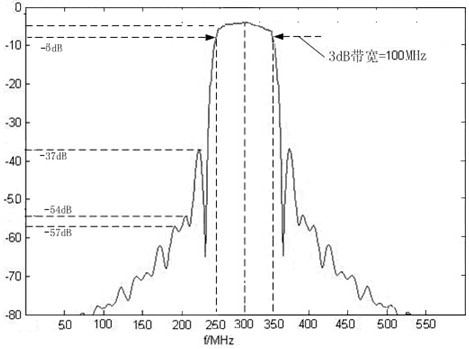

[0038] Taking the ladder-shaped IDT structure as an example, implement a three-dimensional structure gain compensation SAW device: the ladder-shaped IDT structure is as follows figure 2 The mark 2 in the figure represents the input IDT; the mark 3 in the figure represents the output IDT; the mark 4 in the figure represents the bus bar and reflection grid; the mark 5 in the figure represents the dotted line The structure diagram shows the core of the surface acoustic wave filter manufactured by etching the stepped IDT structure on the surface of the piezoelectric film. The width of the interdigitated electrodes is a, and the electrode interval is b. The amplitude-frequency characteristics of the surface acoustic wave filter or surface acoustic wave resonator designed when a=b=7.5 micron, interdigital logarithm N=30 are as follows image 3 shown. The substrate material is AlN piezoelectric thin film with C-axis preferential orientation (100). The fabricated samples were teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com