Adhesive composition using polyamide-imide resin

A polyamide-imide resin and composition technology, applied in the direction of film/sheet adhesive, adhesive type, non-polymer adhesive additive, etc., can solve the problem of not being able to obtain heat resistance, Issues such as flexible adhesiveness, insulating solvent solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

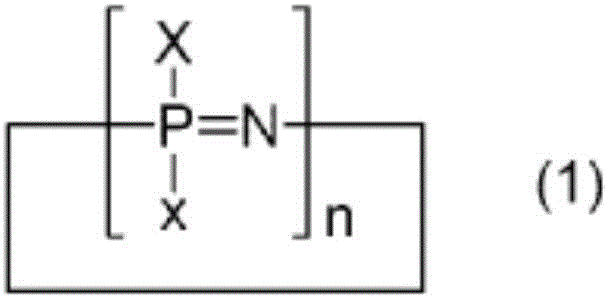

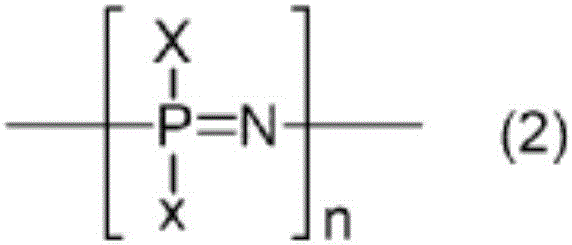

Image

Examples

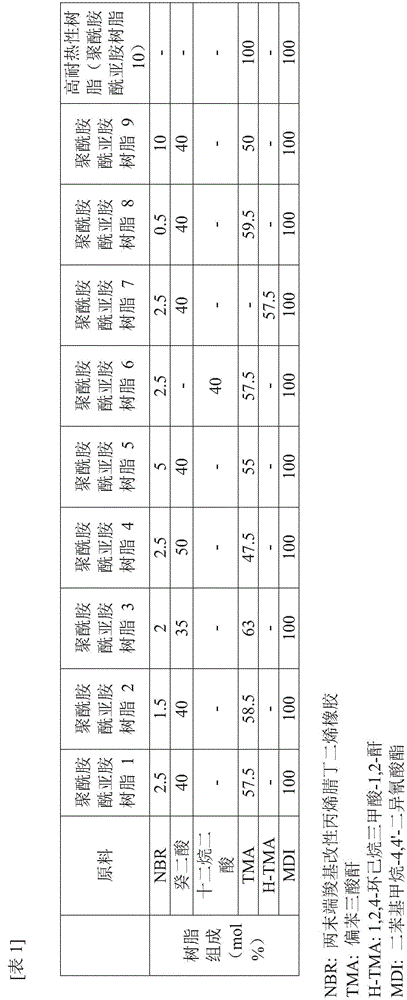

Embodiment

[0088] Hereinafter, the effects of the present invention will be demonstrated through examples, but the present invention is not limited thereto. In addition, the characteristic evaluation in an Example was performed by the following method.

[0089] adhesiveness

[0090] Apply the adhesive composition solution to a polyimide film (Apicar 12.5NPI manufactured by Kaneka Co., Ltd.) to a thickness of 20 μm after drying, and dry it with a hot air dryer at 140°C for 3 minutes to obtain a B-stage state sample. Using a vacuum pressure laminator at 160° C., 3 MPa, and 30 seconds under reduced pressure, the adhesive-coated surface of the B-stage sample and the glossy surface of the copper foil (BHY thickness 18 μm manufactured by JX Nippon Mining Co., Ltd.) were heated. Crimp. Then, it heat-cured at 150 degreeC for 4 hours. Using a tensile tester (Shimadzu Autograph AG-X plus), the cured sample was peeled off the polyimide film at a speed of 50 mm / min in a direction of 90° under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com