Method for reducing campylobacteria by applying propionic acid in primary-stage production process of broilers

A production process and technology of Campylobacter, which is applied in the field of reduction of Campylobacter in broilers, can solve the problems of intestinal growth, production performance and meat quality of broilers, and achieve the effect of reducing the number of Campylobacter and the range of acidity in a reasonable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Screening of lethal critical concentration in vitro

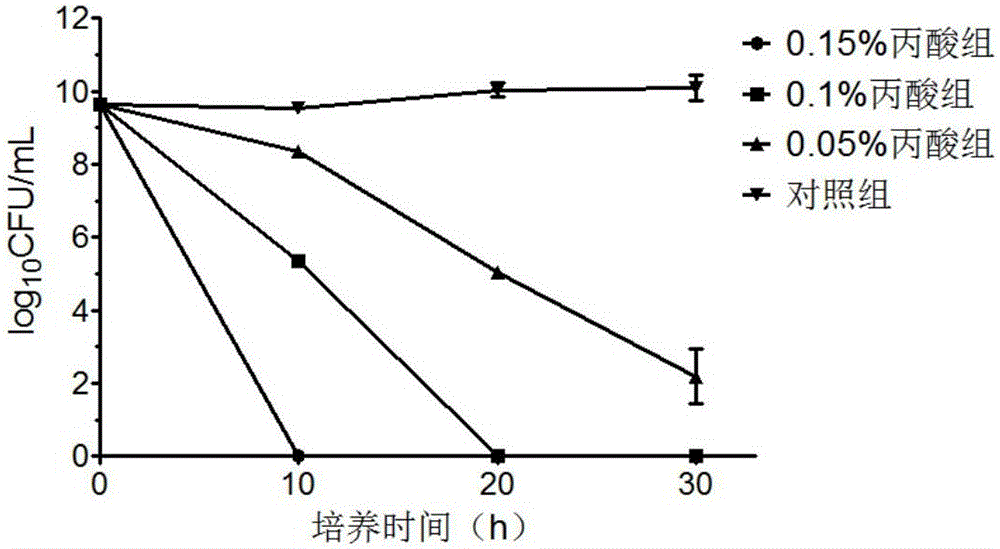

[0022] Firstly, the inhibitory efficiencies of propionic acid at three mass concentrations of 0.05%, 0.10%, and 0.15% against Campylobacter were compared. Campylobacter in the same culture state was co-cultured with different concentrations of propionic acid for 30 hours at 42°C, and the initial concentration of Campylobacter was 5×10 7 CFU / mL was counted every 10 hours on the plate, and the growth curve of Campylobacter jejuni 11168 strain was drawn after adding various concentrations of malic acid. The results show that among the three mass concentrations of propionic acid of 0.05%, 0.1%, and 0.15%, the concentration of Campylobacter jejuni 11168 bacterial strain can be reduced to an undetectable level within 20h, which is the propionic acid of 0.1% mass concentration (see figure 1 ).

Embodiment 2

[0024] practical application

[0025] In order to judge the feasibility of the scheme, experiments were carried out on farm broilers to verify the effect of propionic acid on Campylobacter in the intestinal tract of broilers. According to the feeding requirements of commercial broilers, the ambient temperature and humidity are controlled. One week before the broilers enter the chicks, they are fumigated and disinfected, and all chicken cages and utensils are washed clean, and the whole process is regularly disinfected. Cages were adopted, water was supplied from plastic drinking fountains, and food and water were freely available. The immunization procedures of each group were the same during the feeding period. Sixty 5-week-old broilers with relatively small individual differences were selected and randomly divided into three groups, namely the propionic acid group and the control group, with 20 chickens in each group. The pH of the daily drinking water of the broilers was ...

Embodiment 3

[0034] Determination of the effect on Campylobacter

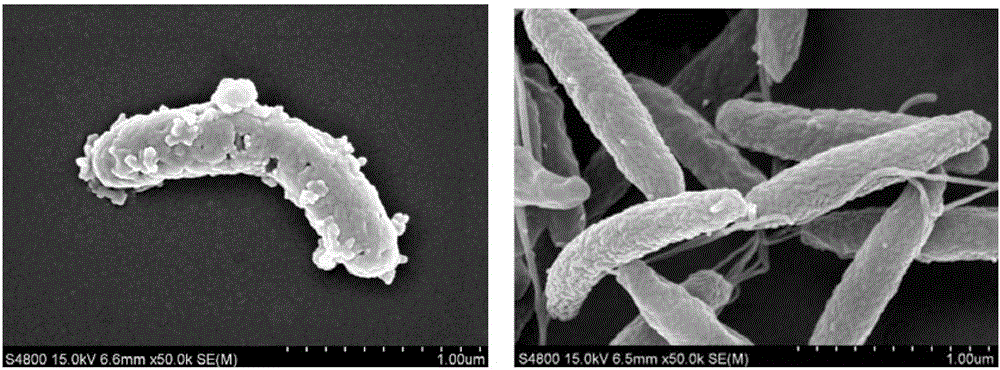

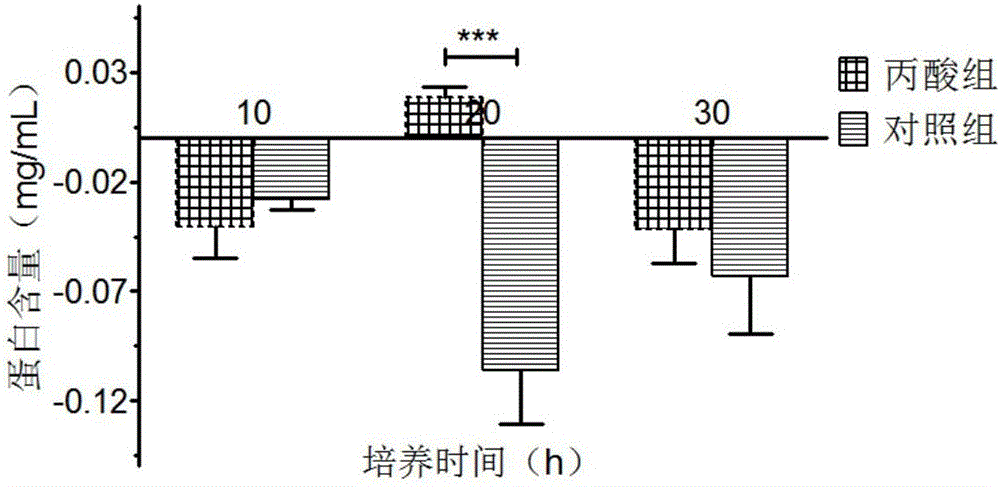

[0035] Scanning electron microscopy (SEM) was used to observe the cell wall of Campylobacter. The specific operation method was as follows: take 800 μL of MH liquid medium, add 100 μL of 1% propionic acid, and replace it with 100 μL of MH liquid medium as a control. Resuscitate the bacteria on CCDA solid medium, culture them under microaerophilic conditions at 42°C for 24 hours, harvest the bacteria with MH liquid medium, and adjust the inoculation concentration of Campylobacter to 5×10 8 CFU / mL. Add 100 μL of the diluted bacterial solution to the prepared organic acid solution. 42 ° C shaker, 120 rpm culture under microaerophilic conditions. The bacterial suspension was taken at 20 hours as the sample to be tested to ensure that the two experimental groups were carried out at the same time. Centrifuge at 5000rpm for 5min at 4°C and discard the supernatant. Subsequent fixation, dehydration, sample drying and scanning el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com