Chitosan alginate dressing and freeze-drying preparation method thereof

A technology of chitosan alginate and chitosan, applied in pharmaceutical formulation, application, medical science and other directions, can solve problems such as cytotoxicity, achieve the effect of simple material, promote wound healing, and maintain a moist environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

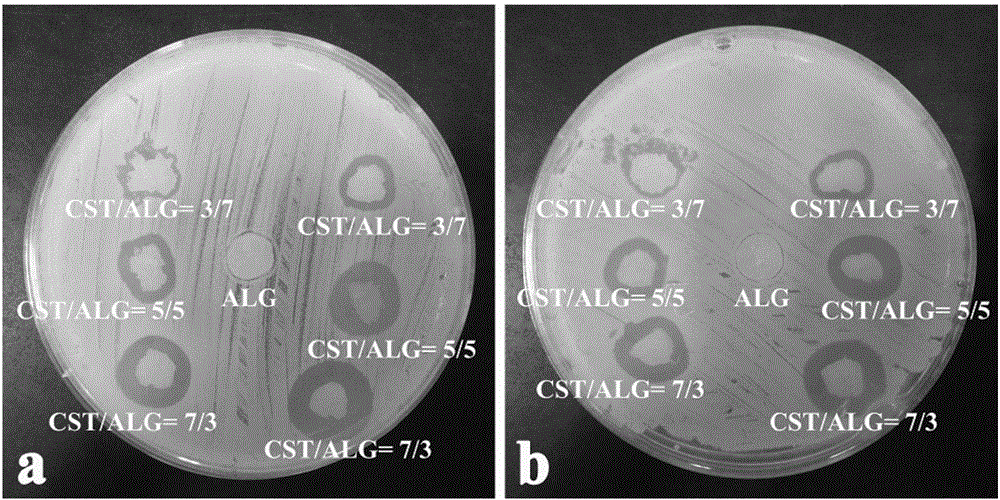

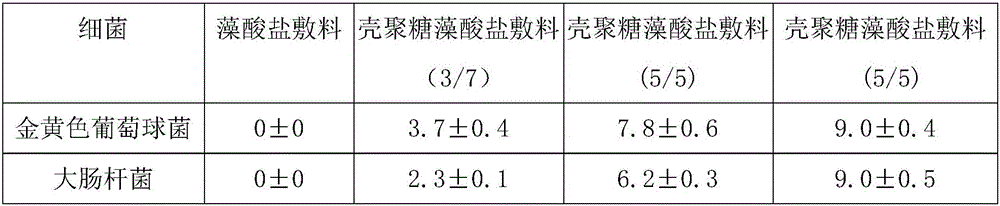

[0018] The making of embodiment 1 novel chitosan alginate dressing

[0019] 1.5g high molecular weight chitosan (molecular weight is 800,000), 1.5g low molecular weight chitosan (molecular weight is 3 thousand) is added in 97g weakly acidic solution, makes 3% chitosan mixed solution after stirring; Add 3g of sodium alginate to 97g of deionized water, and mix with a magnetic stirrer to obtain a sodium alginate solution with a mass concentration of 3%; the chitosan mixed solution and the sodium alginate solution are blended at a volume ratio of 3:7, and Add glycerol as a plasticizer according to 10% of the volume of the blend solution, stir and mix at a high speed with a homogenizer to obtain a chitosan-sodium alginate mixture; pour the chitosan-sodium alginate mixture into a six-hole plate or culture dish, freeze-dried for 12 hours to obtain a freeze-dried film; the freeze-dried film was placed in 5% CaCl 2 The solution was soaked and cross-linked for 1 hour, rinsed with disti...

Embodiment 2

[0020] The making of embodiment 2 novel chitosan alginate dressings

[0021]1.5g high molecular weight chitosan (molecular weight is 800,000), 1.5g low molecular weight chitosan (molecular weight is 3 thousand) is added in 97g weakly acidic solution, makes 3% chitosan mixed solution after stirring; Add 3g of sodium alginate to 97g of deionized water, and mix with a magnetic stirrer to obtain a sodium alginate solution with a mass concentration of 3%; the chitosan mixed solution and the sodium alginate solution are blended at a volume ratio of 5:5, and Add glycerol as a plasticizer according to 10% of the volume of the blend solution, stir and mix at a high speed with a homogenizer to obtain a chitosan-sodium alginate mixture; pour the chitosan-sodium alginate mixture into a six-hole plate or culture dish, freeze-dried for 18 hours to obtain a freeze-dried film; the freeze-dried film was placed in 5% CaCl 2 The solution was soaked and cross-linked for 1 h, rinsed with distille...

Embodiment 3

[0022] The making of embodiment 3 novel chitosan alginate dressings

[0023] 1.5g high molecular weight chitosan (molecular weight is 800,000), 1.5g low molecular weight chitosan (molecular weight is 3 thousand) is added in 97g weakly acidic solution, makes 3% chitosan mixed solution after stirring; 3g of sodium alginate was added to 97g of deionized water, and mixed with a magnetic stirrer to obtain a sodium alginate solution with a mass concentration of 3%; the chitosan mixed solution and the sodium alginate solution were blended in a volume ratio of 7:3, and Add glycerol as a plasticizer according to 10% of the volume of the blend solution, stir and mix at a high speed with a homogenizer to obtain a chitosan-sodium alginate mixture; pour the chitosan-sodium alginate mixture into a six-hole plate or culture dish, freeze-dried for 24 hours to obtain a lyophilized film; the lyophilized film was placed in 5% CaCl 2 The solution was soaked and cross-linked for 1 hour, rinsed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com