New technology for treating industrial volatile organic chemicals (VOCs) waste gas

A new process and waste gas technology, applied in the direction of gas treatment, air quality improvement, membrane technology, etc., can solve the problems of unqualified treatment efficiency, inconvenient use and management, single application form, etc., to improve equipment efficiency, reduce operating costs, equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

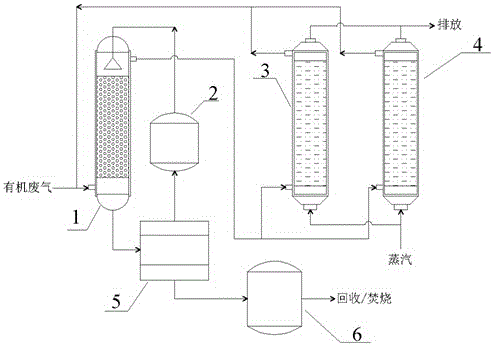

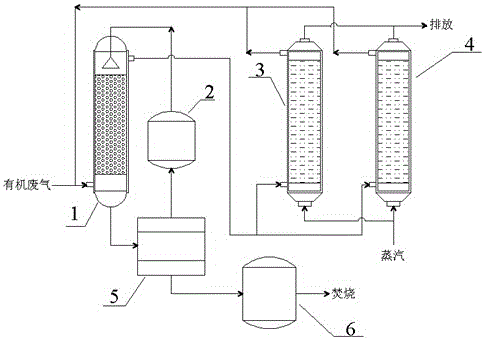

[0030] Specific embodiment 1 such as figure 2 Shown: the VOCs waste gas is passed into the absorption treatment system composed of the first-stage absorption tower 1, and the aqueous solution containing surfactant is used for absorption treatment under the conditions of normal pressure and 25 ℃, and then the waste gas after the absorption treatment is passed through Into the adsorption and desorption system composed of adsorption tower 3 and spare adsorption tower 4, activated carbon is used for adsorption treatment under normal pressure and 35°C. The exhaust gas removal rate after two stages of absorption and adsorption is over 98%. Compliance with emission standards, discharge. After the activated carbon in the adsorption tower 3 reaches a saturated state, the air intake is stopped, and the exhaust gas is passed into the standby adsorption tower 4 for processing. The activated carbon in the adsorption tower 3 is desorbed by passing steam at 120°C to the bottom of the adsorpt...

specific Embodiment 2

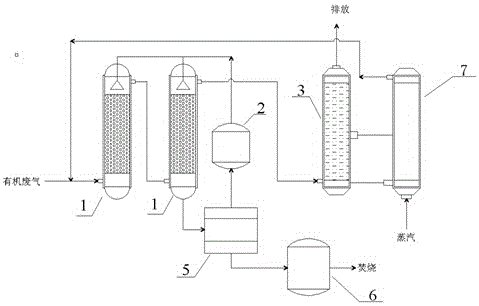

[0032] Specific embodiment 2 such as image 3 Shown: the VOCs waste gas is passed into the absorption treatment system composed of two-stage absorption tower 1, and the aqueous solution containing surfactant is used for absorption treatment under the conditions of normal pressure and 30 ℃, and then the waste gas after the absorption treatment is passed through In the adsorption and desorption system composed of the first-stage adsorption tower 3 and the desorption tower 9, activated carbon is used for adsorption treatment, and the exhaust gas removal rate after absorption and adsorption two-stage treatment can reach 98%, which meets the emission standards for discharge. The activated carbon in the adsorption tower 3 reaches the saturation state and then enters the desorption tower 9. The desorption treatment is carried out by passing 120°C steam into the desorption tower. The desorbed activated carbon can be recycled back to the adsorption tower 3 In use, the desorbed waste gas ...

specific Embodiment 3

[0034] Specific embodiment 3 such as Figure 4 Shown: the VOCs waste gas is passed into the absorption treatment system composed of the first-stage absorption tower 1, and the washing oil is used for absorption treatment under the conditions of normal pressure and 25 ℃, and then the waste gas after the absorption treatment is passed into the two-stage In the adsorption and desorption system composed of the adsorption tower 3 and the desorption tower 9, activated carbon is used for adsorption treatment, and the exhaust gas removal rate after the two-stage treatment of absorption and adsorption is above 98%, which meets the emission standards and is discharged. The activated carbon in the adsorption tower 3 reaches the saturation state and then enters the desorption tower 9. The desorption process is carried out by passing 120°C steam into the desorption tower. The desorbed activated carbon can be returned to the adsorption tower 3 for recycling. The desorbed waste gas is returne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com