Antibacterial and antifouling oil-water separation material and preparation method thereof

A technology of oil-water separation and anti-fouling, applied in the field of water treatment, to achieve good application prospects, simple method, and high-efficiency anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

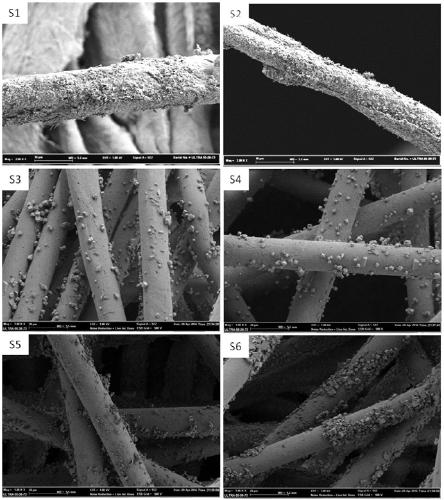

Embodiment 1

[0023] (1) Immerse a 5cm×5cm cellulose filter membrane in distilled water, boil and activate it for 30min, then wash it for later use.

[0024] (2) Immerse the activated cellulose filter membrane in step (1) in 30 mL of copper sulfate solution with a concentration of 0.5 mol / L, stir at room temperature at 120 rpm for 30 min, and slowly adjust the pH of the solution to 11 with NaOH solution of 1.0 mol / L .

[0025] (3) Add 30 mL of glucose solution with a concentration of 0.5 mol / L to the mixed system obtained in step (2), and reduce in situ at 25° C. for 6 h. Then it was taken out, washed and dried to obtain a film material with in-situ deposition of copper oxide inorganic nanoparticles on the surface, which is an antibacterial and antifouling oil-water separation material, named S1.

Embodiment 2

[0027] (1) Immerse a 5cm×5cm cellulose filter membrane in distilled water, boil and activate it for 30min, then wash it for later use.

[0028] (2) Immerse the activated cellulose filter membrane in step (1) in 30 mL of copper acetate solution with a concentration of 1.0 mol / L, stir at room temperature at 120 rpm for 30 min, and slowly adjust the pH of the solution to 10 with 1.0 mol / L of NaOH solution. .

[0029] (3) Add 30 mL of glucose solution with a concentration of 1.0 mol / L to the mixed system obtained in step (2), and reduce in situ at 70° C. for 4 h. Then it was taken out, washed and dried to obtain a film material with in-situ deposition of cuprous oxide inorganic nanoparticles on the surface, which is an antibacterial and antifouling oil-water separation material, named S2.

Embodiment 3

[0031] (1) Immerse a 5cm×5cm polyester filter membrane in 0.1mol / L NaOH solution, boil it for 30min and then wash it for later use.

[0032] (2) Immerse the polyester filter membrane activated in step (1) in 30 mL of copper acetate solution with a concentration of 1.0 mol / L, stir at 120 rpm for 30 min at room temperature, and then slowly adjust the pH of the solution to 12 with 1.0 mol / L NaOH solution.

[0033] (3) Add 30 mL of glucose solution with a concentration of 1.5 mol / L to the mixed system obtained in step (2), and perform in-situ reduction at 120° C. for 3 h. Then it was taken out, washed and dried to obtain a film material with in-situ deposition of cuprous oxide inorganic nanoparticles on the surface, which is an antibacterial and antifouling oil-water separation material, named S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com