Self-cleaning automobile shock absorber triple automatic feeding and pressing machine and its control method

A technology of automatic feeding and triple parts, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, difficulty in ensuring the consistency and qualification of production quality, operator proficiency and individual technical differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

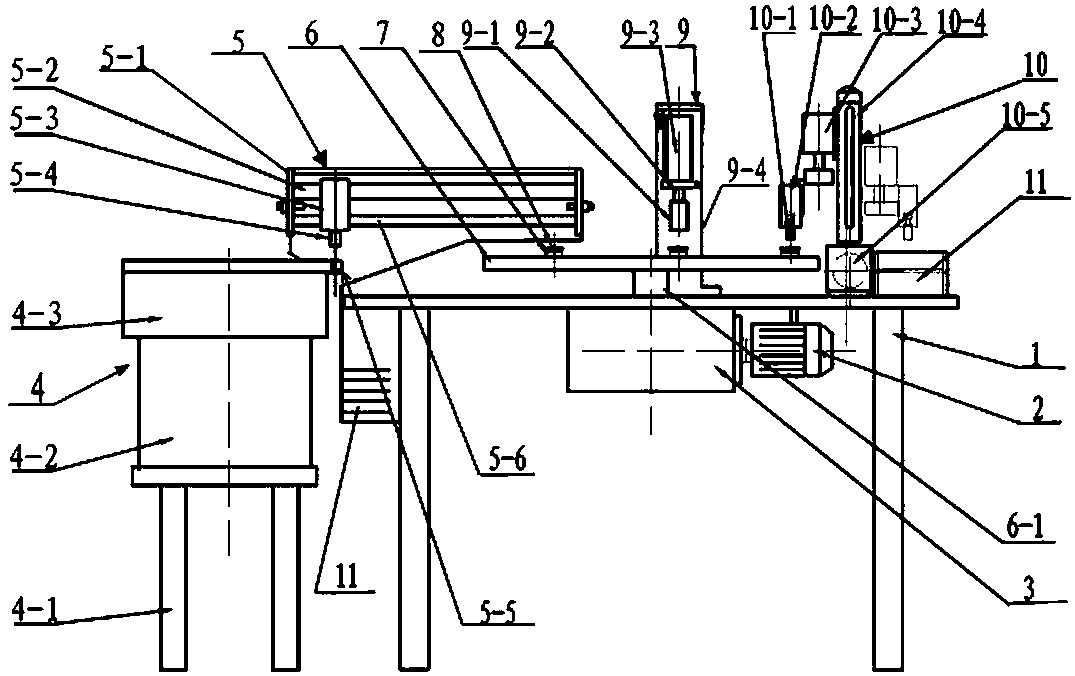

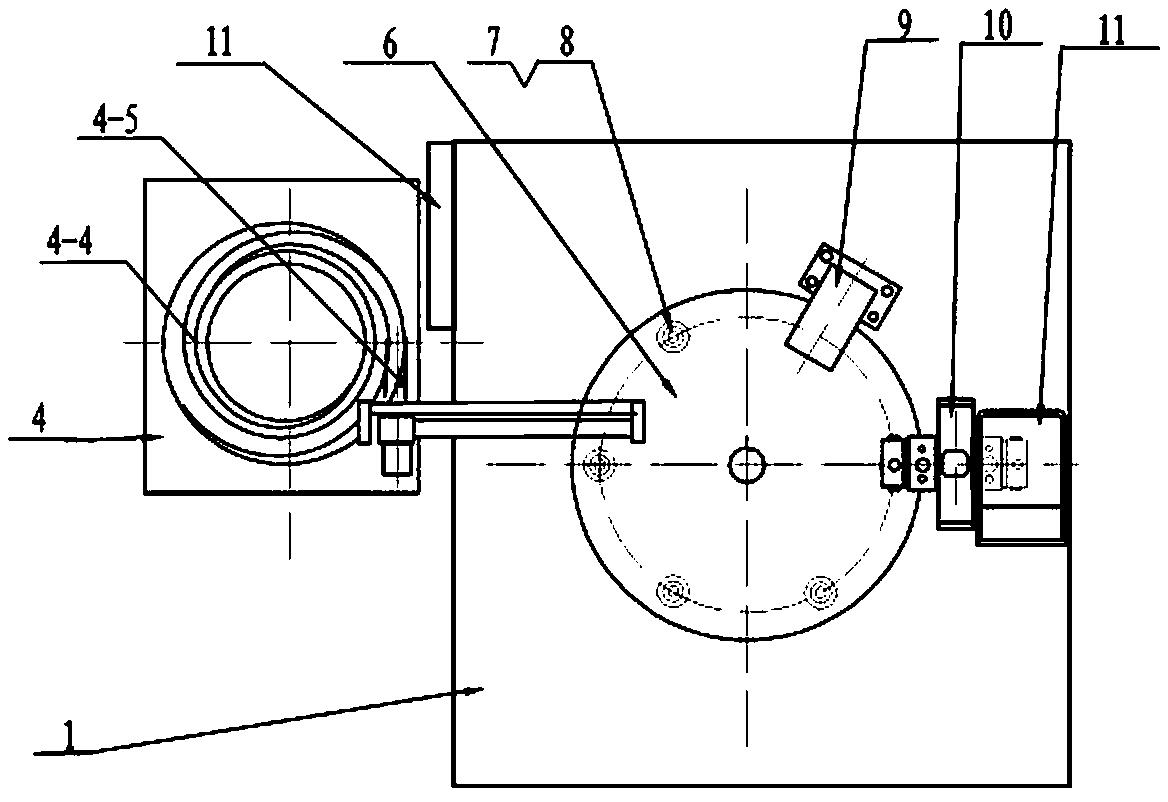

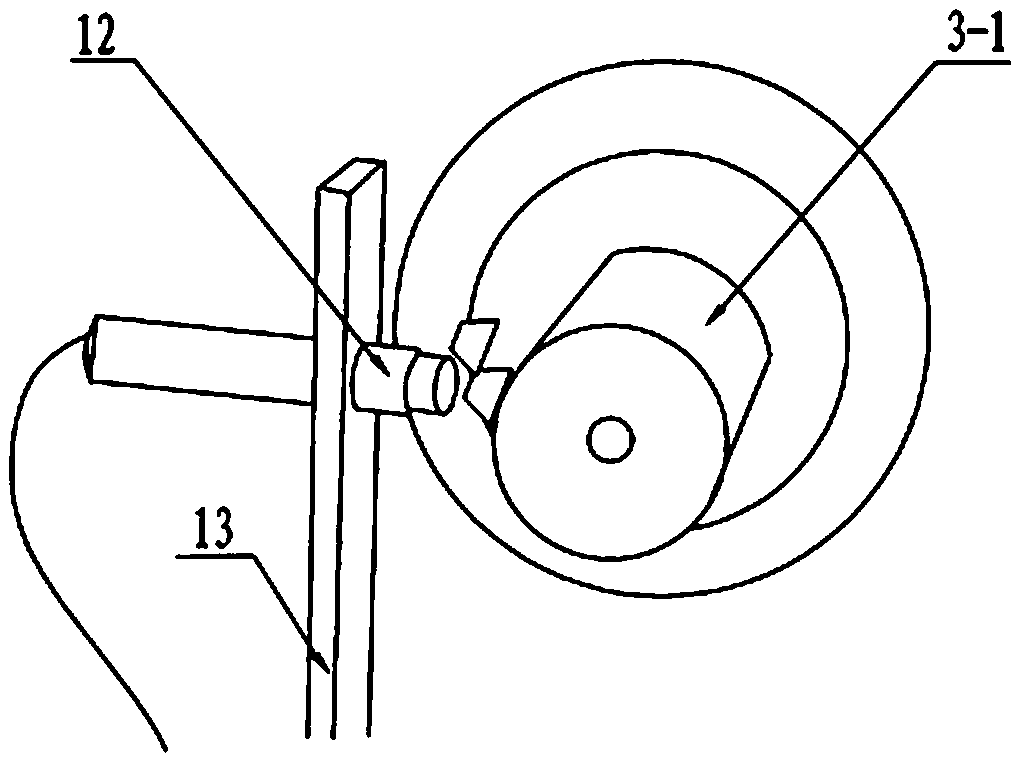

[0033] see figure 1 , figure 2 , the self-cleaning automobile shock absorber tripartite automatic feeding and pressing machine of the present invention includes a mechanical pressing part and an automatic control part, and the mechanical pressing part includes: a workbench 1, a frequency conversion speed regulating motor 2, a divider 3, and a vibrating feeding Mechanism 4, feeding manipulator 5, station turntable 6, pneumatic press-fitting mechanism 9, pneumatic manipulator 10 and receiving box 11, wherein, the workbench 1 is fixed with station turntable 6, station turntable There are several press-fitting stations 7 evenly distributed on the 6, and at least six press-fitting stations 7 are arranged. The press-fitting stations 7 are embedded with a die 8 for press-fitting the triplets of the self-cleaning shock absorber. The bottom of the workbench 1 is equipped with a divider 3, which is a conjugate cam intermittent divider. The input shaft of the divider 3 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com