Following type intelligent crack detection system and method for train wheels

A train wheel and follow-up technology, which is applied in the direction of rim measurement/measurement, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc. It can solve the problems that cannot meet the requirements of flaw detection efficiency, complex internal control logic, and no cloud data transmission, etc. problems, to achieve the effects of sharing and analysis, facilitating data cloud storage, and reducing manual dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

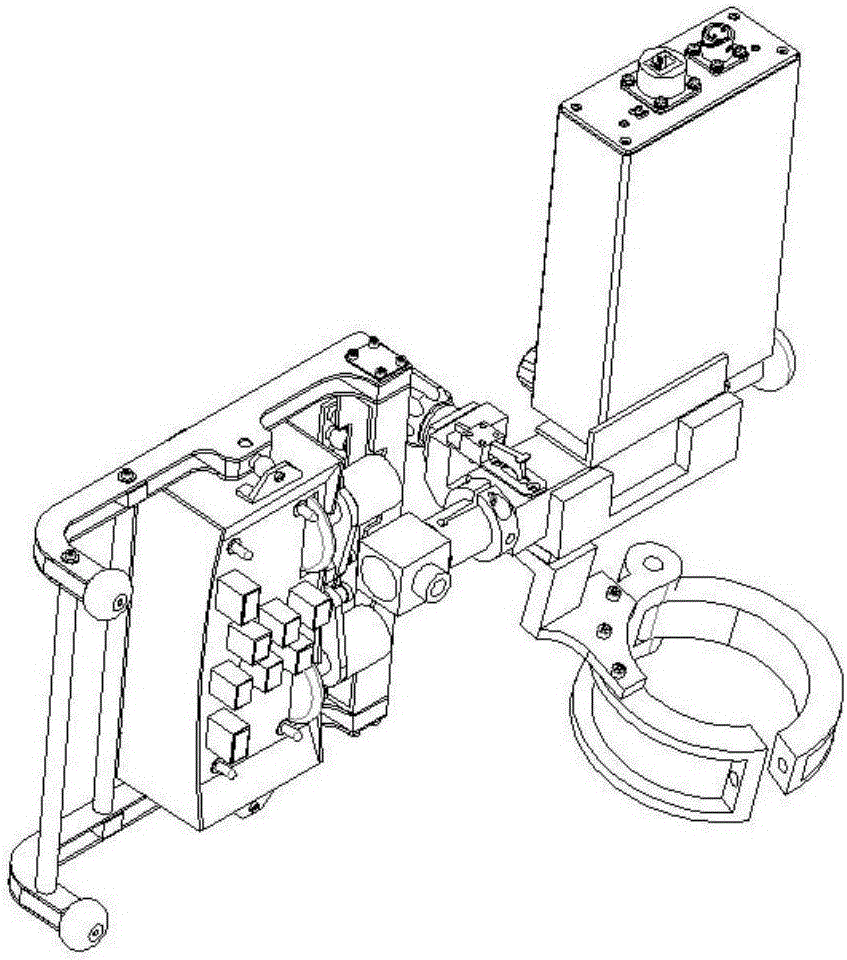

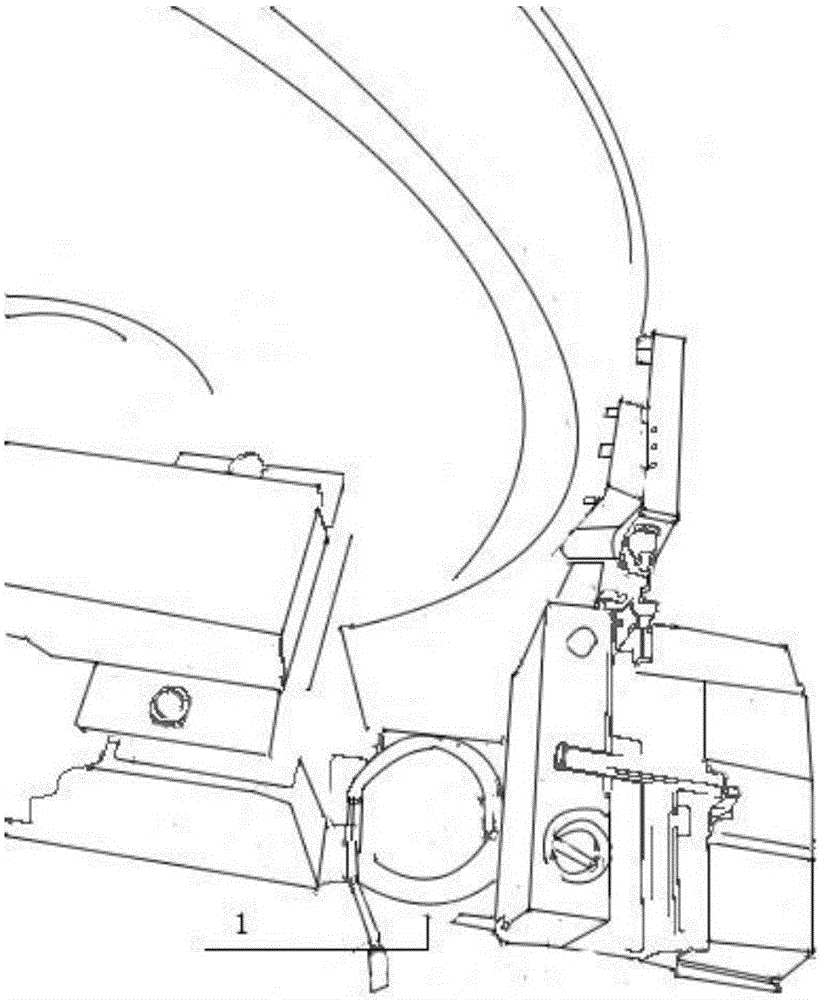

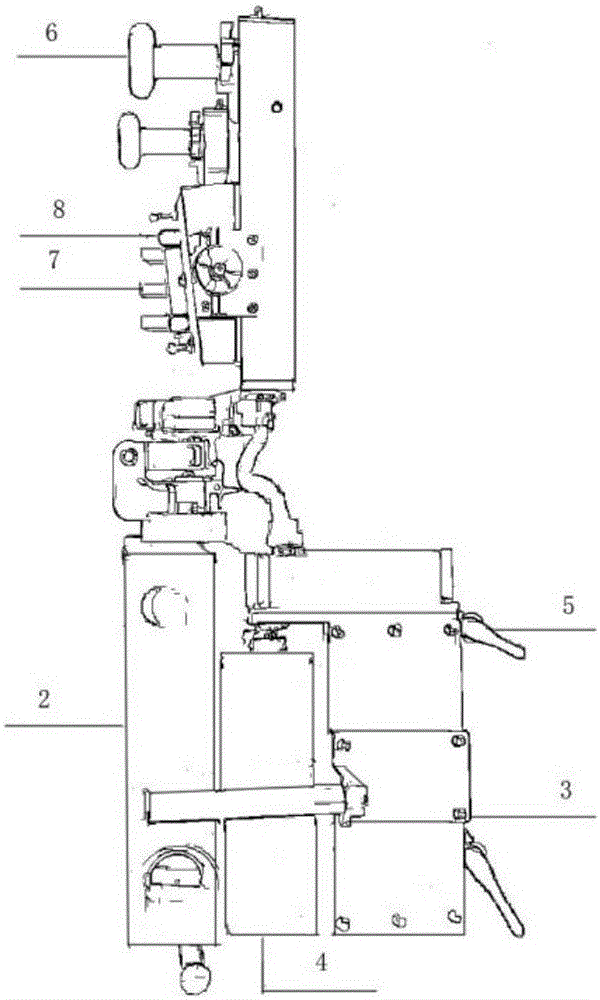

[0043] The train wheel follow-up intelligent flaw detection system of this embodiment, such as figure 2 Shown; including data acquisition modules, such as image 3 Shown; communication module, such as Figure 4 Shown; integrated control module and cloud data transmission module, such as Figure 5 Shown. Data acquisition module ( image 3 ), one or more sets of data acquisition modules work simultaneously to detect different wheels of the same train; including brackets ( figure 2 (1)) Install the ultrasonic excitation board directly above the bracket ( image 3 (3)) The power supply 4, the water tank 2, the probe 7, the encoder 6, the water pipe, and the nozzle 8 are installed on one side of the bracket. The ultrasonic excitation board connects the probe, the encoder and the motor; the power supply supplies power to the ultrasonic excitation board, the motor, and the client; the client 5 is installed above the bracket and connected to the ultrasonic excitation board; the water t...

Embodiment 2

[0045] The wireless client of the communication module and the data acquisition module are integrated, high-power routing ( Figure 4 ) Is placed inside the control cabinet, integrated with the comprehensive control module and the cloud transmission module, the structure diagram is as follows Figure 5 , The distance between the client and the wireless router is less than or equal to 50m, and the gain antenna is greater than or equal to 2dB. The operating steps of the software system are as follows: firstly, verify that the user name and password are correct, and enter the flaw detection system according to user authority; secondly, enter the detection information; again, send the start acquisition command to start real-time flaw detection; finally, replay the real-time detection results, And produce reports, and start cloud data transmission at the same time, the detailed workflow is as Image 6 Shown. The real-time flaw detection interface of the software is like Figure 7 As ...

Embodiment 3

[0047] Cloud data transmission module, including server, network card, storage cloud. When the software system issues a cloud storage command, the software first converts the data into the format required for cloud transmission and temporarily stores it on the industrial computer, then starts the server calling program, the server calling program continuously reads the data, and transfers the data through the 3G / 4G network card The data is sent to the cloud. The cloud has a large storage space and multiple interfaces. Each interface has a unique address. The upload and download of different types of data can be realized through the cloud interface, so as to realize the backtracking of the original data and the alarm data. shared. The workflow of the cloud data transmission module is as follows Picture 9 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com