Method for preparing 2-cyanoethyl-5-norbornadiene-2-aldehyde in micro-structural reactor

A microstructure reactor, cyanoethyl technology, applied in chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc., can solve the problem of producing a large amount of solid residue, the need to grind the catalyst into powder, and the large amount of acrylonitrile used problems, to achieve the effect of less solid residue, less aggregation, and strong mass and heat transfer capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

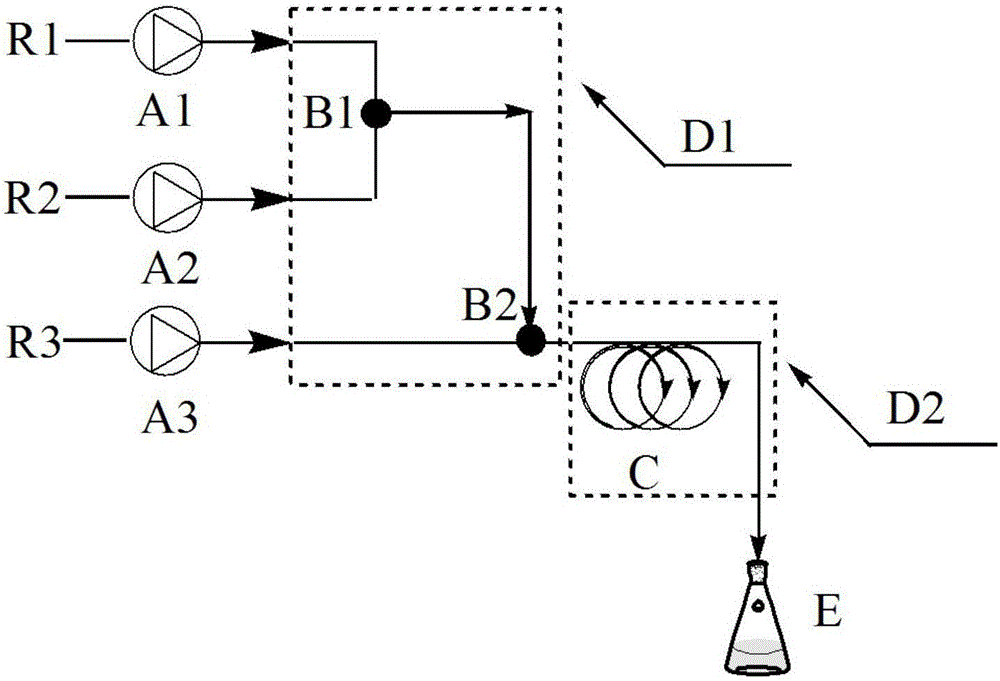

[0018] Such as figure 1 Shown: 5-norbornene-2-aldehyde A1 is transported into the first micro-mixer B1 (T-shaped three-way mixer, inner diameter: 1mm) to mix with the catalyst solution transported by A2, and the temperature of the first constant temperature water area D1 is 25°C , residence time 10s, then mixed with the acrylonitrile transported by A3 in the second micro-mixer B2 (T-type three-way mixer, inner diameter: 1mm), after mixing, enter (microchannel reactor) residence time extension tube C (inner diameter: 1mm), the temperature of the second constant temperature water area D2 is 60°C, the residence time is 7min, and finally enters the product collection bottle E. The mass ratio of feed 5-norbornene-2-aldehyde, acrylonitrile, toluene, potassium tert-butoxide to tert-butanol is 1:0.7:3:0.015, and the concentration of the tert-butanol solution of potassium tert-butoxide is 10 wt%. Total flow rate 1.143 mL / min. The solid content in the reaction solution was 1.24‰, and ...

Embodiment 2

[0020] Such as figure 1 Shown: 5-norbornene-2-aldehyde is transported by A1 into the first micro-mixer B1 (T-shaped three-way mixer, inner diameter: 1mm) and mixed with the catalyst solution transported by A2, the temperature of the first constant temperature water area D1 is 25 ℃, the residence time is 10s, and then mixed with the acrylonitrile second micro-mixer B2 (T-type three-way mixer, inner diameter: 1mm) delivered by A3, after mixing, it enters (microchannel reactor) residence time extension tube C (inner diameter: 1mm), the temperature of the second constant temperature water area D2 is 50°C, the residence time is 5min, and finally enters the product collection bottle E. The mass ratio of feed 5-norbornene-2-aldehyde, acrylonitrile, toluene, potassium tert-butoxide to tert-butanol is 1:1.47:3:0.02, and the concentration of the tert-butanol solution of potassium tert-butoxide is 14.8wt%. , the total flow rate is 1.78mL / min. The solid content in the reaction solution ...

Embodiment 3

[0022] Such as figure 1 Shown: 5-norbornene-2-aldehyde is transported by A1 into the first micro-mixer B1 (T-shaped three-way mixer, inner diameter: 1mm) and mixed with the catalyst solution transported by A2, the temperature of the first constant temperature water area D1 is 10 ℃, residence time 60s, and then mixed with the acrylonitrile second micro-mixer B2 (T-shaped three-way mixer, inner diameter: 1mm) delivered by A3, and then enter (microchannel reactor) residence time extension tube C (inner diameter: 1mm), the temperature of the second constant temperature water area D2 is 60°C, the residence time is 7min, and finally enters the product collection bottle E. The mass ratio of feed 5-norbornene-2-aldehyde, acrylonitrile, toluene, potassium tert-butoxide to tert-butanol is 1:0.9:2:0.015, and the concentration of the tert-butanol solution of potassium tert-butoxide is 10wt% total Flow rate 1.244mL / min. The solid content in the reaction solution was 2.71‰, and the conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com