Fusible non-curing rubber asphalt waterproof coating and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, fireproof coating, coating, etc. It can solve the problems of high pollution in the production process of non-curing waterproof coating, difficult melting of non-curing waterproof coating, and long remelting time, etc. Achieve good creep and self-healing properties, less side effects, and even heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

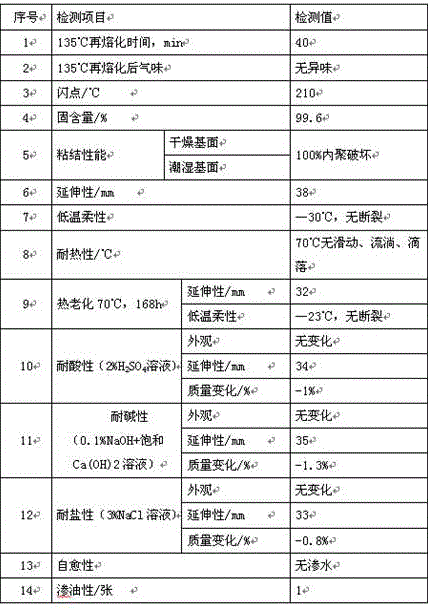

[0030] Example 1 A kind of fusible non-curing rubber asphalt waterproof coating and its preparation method

[0031] A fusible non-curing rubber asphalt waterproof coating, the mass percent of each raw material component is:

[0032] 25-45 parts of asphalt, 10-15 parts of naphthenic oil, 8-15 parts of oil-extended styrene-butadiene rubber (oil-extended SBR), 3-5 parts of low-molecular polymer modifier, oil-extended block copolymerized styrene-butadiene rubber ( Oil-filled SBS) 2-8 parts, thermal conductive filler 6-12 parts, filler 10-30 parts, asphalt deodorant 0.5-1.5 parts.

[0033] The raw materials described therein are as follows:

[0034] 1. Asphalt is 70#, 90# road modified asphalt.

[0035] 2. Environmentally friendly naphthenic oil, Karamay Oilfield Company, model 4010, flash point above 200°C.

[0036] 3. Oil-extended styrene-butadiene rubber SBR1753 is filled with environmentally friendly aromatic oil, which is refined from aromatic oil to remove harmful componen...

Embodiment 2

[0050] Example 2 A kind of fusible non-curing rubber asphalt waterproof coating and its preparation method

[0051] A fusible non-curing rubber asphalt waterproof coating, the mass percent of each raw material component is:

[0052] 25-45 parts of asphalt, 10-15 parts of naphthenic oil, 8-15 parts of oil-extended styrene-butadiene rubber (oil-extended SBR), 3-5 parts of low-molecular polymer modifier, oil-extended block copolymerized styrene-butadiene rubber ( Oil-filled SBS) 2-8 parts, thermal conductive filler 6-12 parts, filler 10-30 parts, asphalt deodorant 0.5-1.5 parts.

[0053] The raw materials described therein are as follows:

[0054] 1. Asphalt is 70#, 90# road modified asphalt.

[0055] 2. Environmentally friendly naphthenic oil, Karamay Oilfield Company, model 4010, flash point above 200°C.

[0056] 3. Oil-extended styrene-butadiene rubber SBR1753 is filled with environmentally friendly aromatic oil, which is refined from aromatic oil to remove harmful components...

Embodiment 3

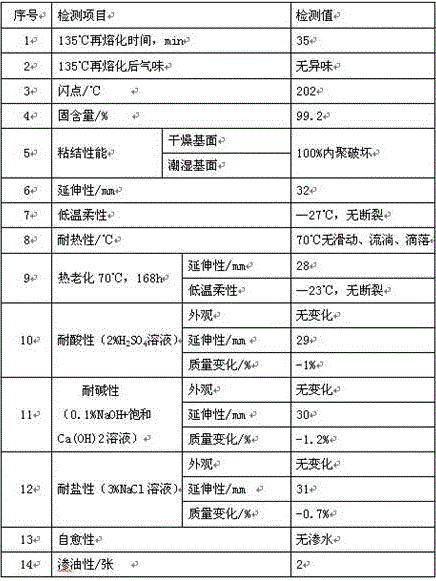

[0070] Example 3 A kind of fusible non-curing rubber asphalt waterproof coating and its preparation method

[0071] A fusible non-curing rubber asphalt waterproof coating, the mass percent of each raw material component is:

[0072] 25-45 parts of asphalt, 10-15 parts of naphthenic oil, 8-15 parts of oil-extended styrene-butadiene rubber (oil-extended SBR), 3-5 parts of low-molecular polymer modifier, oil-extended block copolymerized styrene-butadiene rubber ( Oil-filled SBS) 2-8 parts, thermal conductive filler 6-12 parts, filler 10-30 parts, asphalt deodorant 0.5-1.5 parts, n-butanol 3-5 parts, phosphorus pentoxide 1-2 parts, N , 2-3 parts of N-dimethylacetamide, 2-3 parts of succinic anhydride, 2-3 parts of terrasite ore powder, 1-2 parts of hexafluoropropylene, 2-4 parts of alkyl succinimide, 2 -0.5-1 part of hydroxy-4-methoxybenzophenone.

[0073] The raw materials described therein are as follows:

[0074] 1. Asphalt is 70#, 90# road modified asphalt.

[0075] 2. Env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com