Offshore drilling marine riser resistant to deepwater conquassation and manufacturing method of offshore drilling marine riser

A technology for offshore drilling and risers, which is applied in the direction of drill pipes, drilling equipment, drill pipes, etc., and can solve problems such as large ovality of steel pipes, low toughness of welded joints, and reduced crush resistance of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

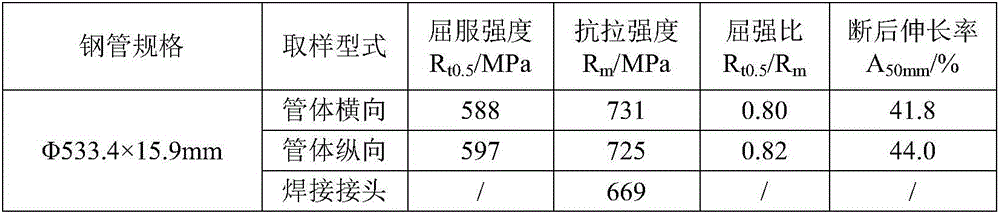

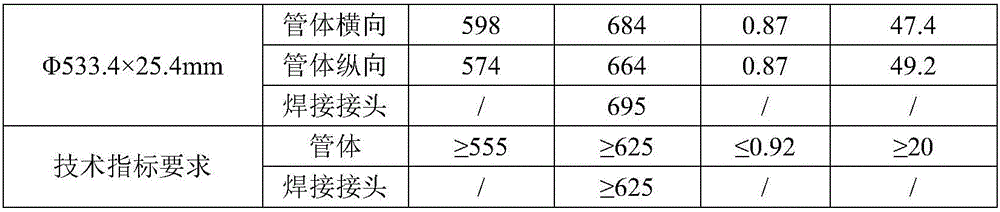

[0039] Combining the manufacturing examples of Φ533.4mm×15.9mm and Φ533.4mm×25.4mm anti-deep water crushing marine drilling risers, the embodiments of the present invention are as follows:

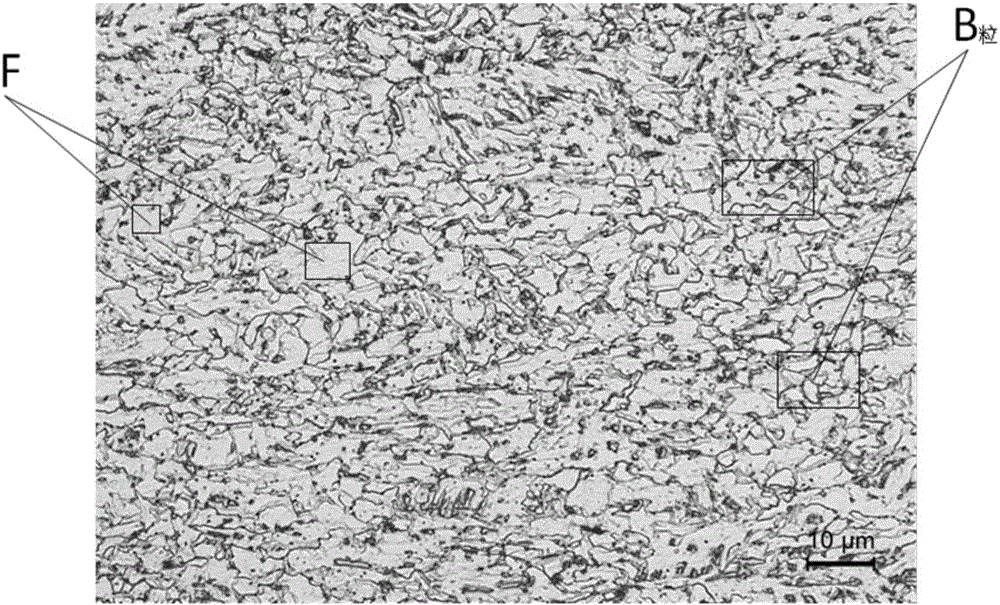

[0040] 1. The marine drilling riser pipe material with anti-deep water crushing contains C: 0.04%, Si: 0.14%, Mn: 1.78%, P: 0.012%, S: 0.002%, Ni: 0.22%, Cr: 0.23 according to the mass percentage %, Cu: 0.18%, Mo: 0.20%, Nb: 0.06%, V: 0.04%, Ti: 0.012%, Al: 0.02% to 0.06%, N: 0.005%, B: 0.0003%, Ca: 0.002%, Ti / N: 2.4, Nb+V+Ti=0.112%, the balance is Fe and unavoidable impurities, its welding crack sensitivity index Pcm=0.17, the microstructure of the pipe is mainly composed of ferrite and bainite Composite fine-grained structure (such as figure 1 Shown), the bainite fraction is above 80%. The pipe has the characteristics of high strength, high toughness, corrosion resistance and good weldability.

[0041] 2. Manufacture of deep-water fracturing-resistant marine drilling riser LSA welded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com