Heat exchange system of novel pipe plate-free methanol oxidizer

A heat exchange system, no tube sheet technology, applied in the direction of heat exchanger types, indirect heat exchangers, chemical instruments and methods, etc. problems, to achieve the effect of increasing the expansion coefficient, improving the service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

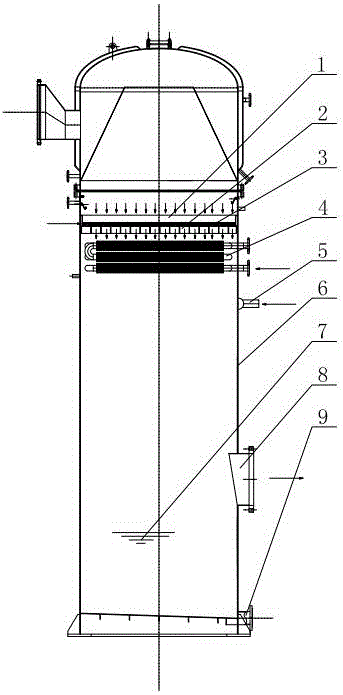

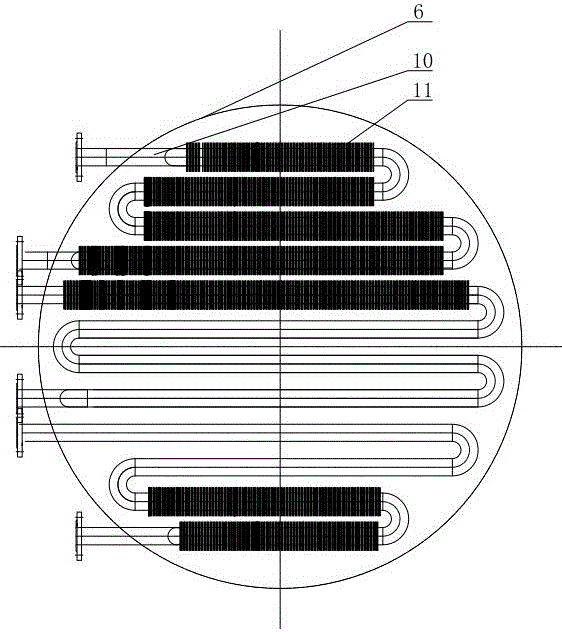

[0026] Such as figure 1 and figure 2 As shown, the heat exchange system of the novel tubeless methanol oxidizer of this embodiment includes a cylinder 6, a reaction layer 3 is installed on the top of the cylinder 6, an oxygen reaction chamber 1 is formed on the top of the reaction layer 3, and the reaction layer 3 The lower part is a fixed reaction bed 2, and the lower part of the fixed reaction bed 2 is equipped with a heat exchange spray system 4, which includes a plurality of serpentine heat exchange tubes 10, and fins 11 are installed on the heat exchange tubes 10 ;A spray port 5 is installed on the side wall of the cylinder body 6, and a reaction gas outlet 8 is arranged on the side wall bottom of the cylinder body 6, and a high-concentration formaldehyde 7 is added in the bottom part of the cylinder body 6, and in the cylinder body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com