Dye-doped liquid crystal microsphere temperature sensor and manufacturing method therefor

A temperature sensor, liquid crystal technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of low sensor sensitivity and inability to meet high-precision measurement requirements, and achieve high laser quality factor, low-cost and easy-to-use equipment. Acquiring, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

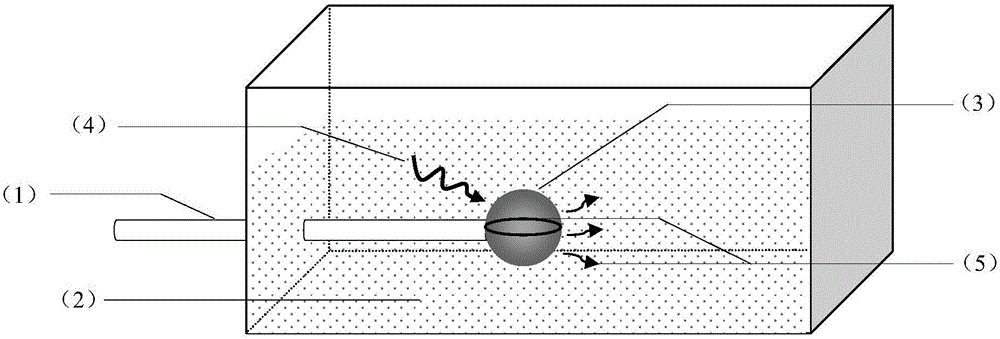

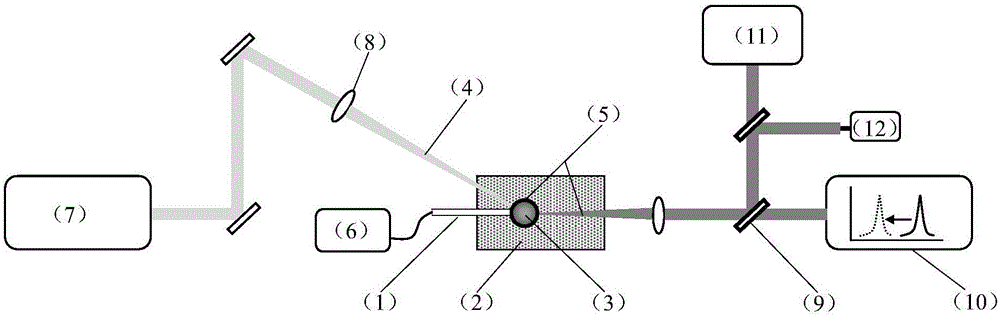

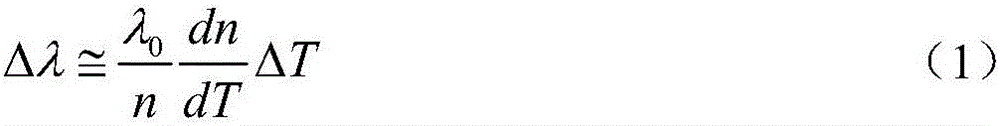

[0023] combine figure 1 with figure 2 , the dye-doped liquid crystal microsphere temperature sensor of the present invention comprises liquid crystal microsphere 3, pulsed laser 7, spectrum analyzer 10 and charge-coupled device CCD11, and described liquid crystal microsphere is formed by the liquid crystal solution of DCM doping, and liquid crystal microsphere The ball is placed in the liquid environment 2 to be tested. The pulse laser 4 emitted by the pulse laser is focused by the optical lens and irradiates the surface of the liquid crystal microsphere. The interface of the measured liquid environment undergoes total internal reflection, amplification, and finally produces a whispering gallery mode laser 5 emission. The light emitted by the liquid crystal microsphere is focused by an optical lens and split by a half-transparent mirror, and a beam of light enters the spectrum analyzer for recording. Spectrum, another beam of light continues to pass through the semi-transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com