Manufacturing method for waveguide amplifier with erbium-doped tantalum oxide ridge structure

A waveguide amplifier and ridge waveguide technology, which is applied in the field of optical communication, can solve the problems of unassisted signal light amplification, difficulty in preparing rectangular waveguides, cluster and concentration quenching, etc., and achieves high yield, good stability and process cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0034] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

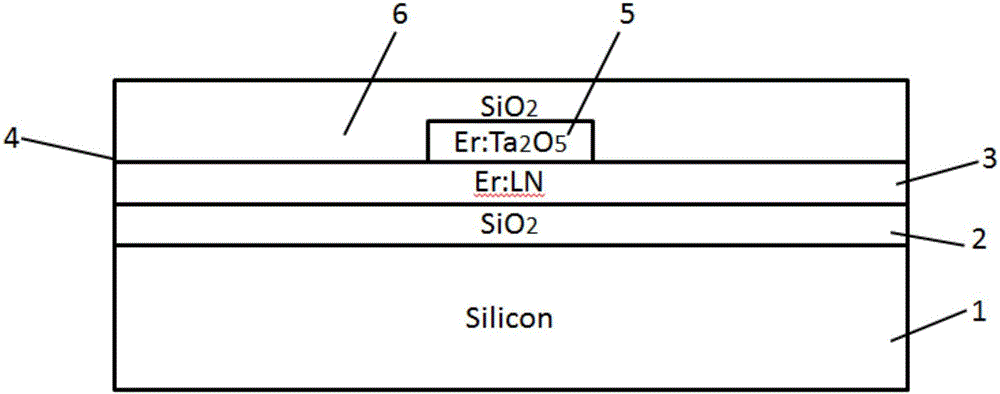

[0035] Such as figure 1 As shown, the present invention provides a method for preparing a waveguide amplifier with an erbium-doped tantalum oxide ridge structure, comprising the following steps:

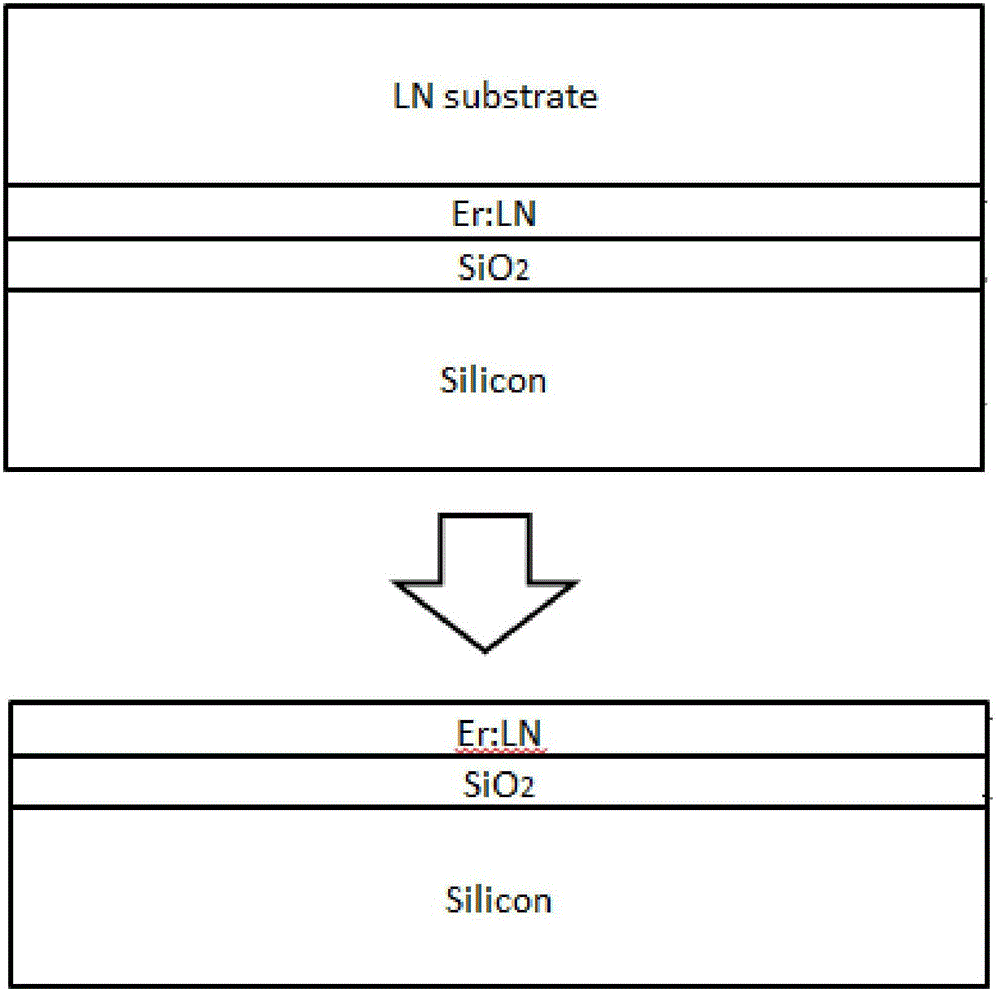

[0036] (1) Select optical-grade double-throwing 0.5mm thick lithium niobate single crystal as the initial material, clean the wafer and plate 10-20nm metal erbium on the surface, and oxidize it in the air at 1100°C to form partially erbium-doped niobium Lithium oxide crystal, the doping concentration of erbium is 0.5-1.5mol%, and a layer of local erbium-doped lithium niobate single crystal thin film is formed on the erbium-doped surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com