Heat treatment method and system for preparing high-performance iron-based nano crystal alloy magnetic core

A technology of iron-based nanocrystals and heat treatment methods, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of low batch processing efficiency, unfavorable high performance of magnetic cores, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The purpose of the present invention is to provide a heat treatment method and system for preparing a high-performance iron-based nanocrystalline alloy magnetic core. By increasing the furnace temperature and heating rate, the heat treatment time can be shortened, and the temperature inside the magnetic core can be effectively controlled to a certain extent. Magnetic ordering, reducing magnetic crystal anisotropy, and improving the performance of the magnetic core.

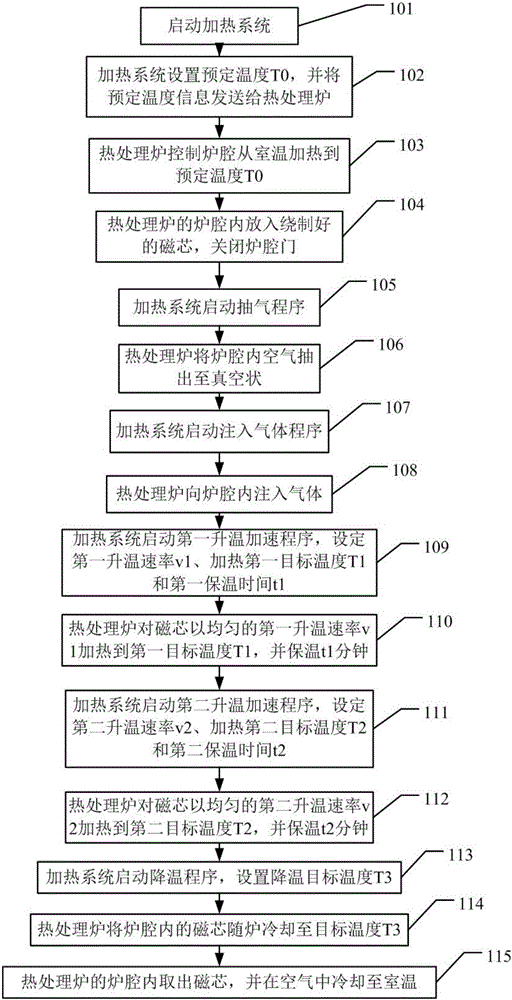

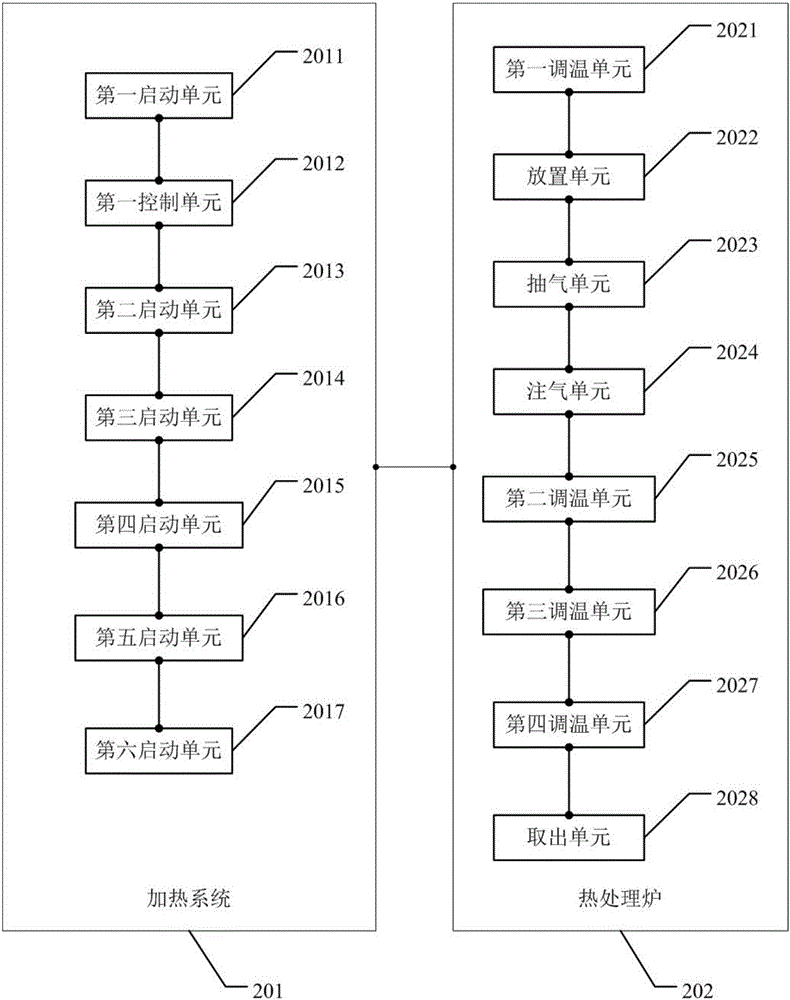

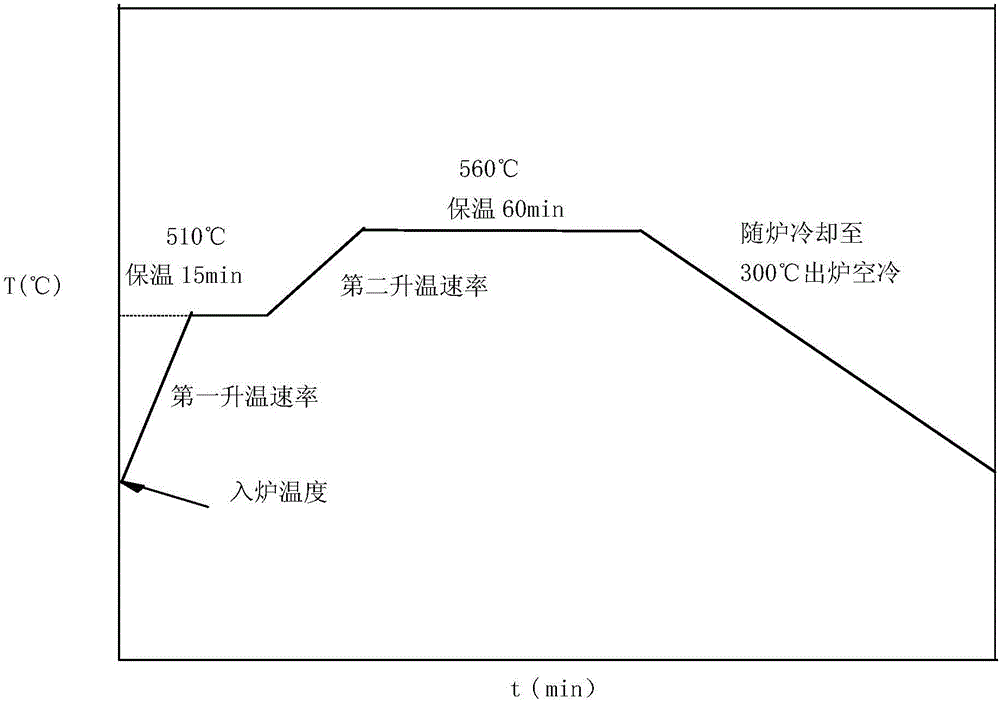

[0064] see below Figure 1-Figure 2 , a heat treatment method for preparing a high-performance iron-based nanocrystalline alloy magnetic core in the present invention and an embodiment are described:

[0065] An embodiment of a heat treatment method for preparing a high-performance iron-based nanocrystalline alloy magnetic core of the present invention includes:

[0066] 101. Start the heating system;

[0067] 102. The heating system sets the predetermined temperature T0, and sends the predetermined tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com