Gluing method for avoiding delaminating between foam plastic core and metal envelope

A foam plastic and metal technology, applied in the field of aircraft composite material manufacturing, can solve the problems of delamination and easy delamination between foam plastic core and metal skin, foam plastic core and metal skin, etc., so as to reduce the repair rate and Scrap rate, low cost, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below.

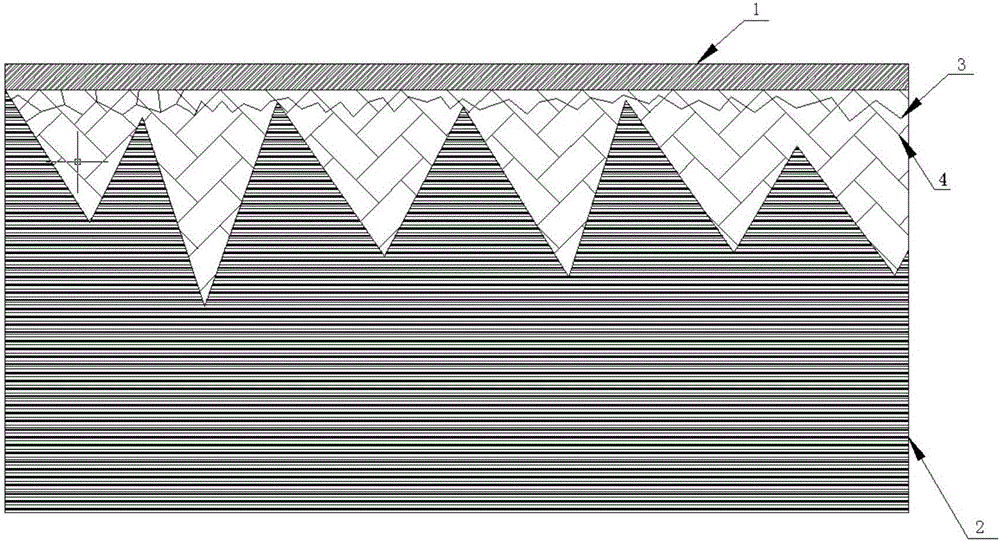

[0019] see figure 1 , which is a schematic diagram of the bonding of the foamed plastic core and the metal skin of the present invention.

[0020] The present invention solves the gluing method for the delamination of the foam plastic core and the metal skin, and its specific process is as follows:

[0021] Step 1: Treatment of the surface to be glued

[0022] Firstly, the metal skin and the surface to be bonded of the foam plastic core placed on the forming flat mold tooling are polished to increase the contact area of the surface to be bonded and the combination of the metal ion and the epoxy bond in the epoxy resin on the microscopic level ;

[0023] Then use a fine white cotton cloth soaked in a volatile solvent (conventional volatile solvents such as acetone, alcohol, etc.) to wipe and clean the surface to be glued between the foam plastic core and the metal skin, replace the fine white cotton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com