A special preparation device for activated clay

A technology of activated clay and secondary activation, applied in the direction of aluminum silicate, silicate, etc., to achieve the effects of reducing production costs, high quality, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

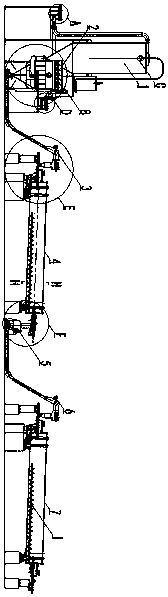

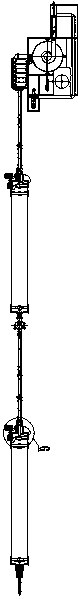

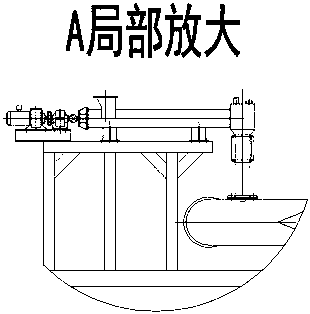

[0022] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , attached Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a special preparation device for activated clay is characterized in that it includes an activation tower assembly 1, an air box pulse bag trap 2, a hoist I 3, a rotary rinsing cylinder 4, a centrifugal dehydrator 5, an hoist II 6, two Second activation drying rotary kiln 7.

[0024] The activation tower assembly 1, air box pulse bag trap 2, elevator I3, rotary rinsing drum 4, centrifugal dehydrator 5, elevator II6, and secondary activation drying rotary kiln 7 are connected in sequence.

[0025]The process equipment layout plan of the activation tower assembly 1, air box pulse bag trap 2, hoist I3, rotary rinsing cylinder 4, centrifugal dehydrator 5, hoist II6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com