Cr(VI) wastewater treatment method

A technology for wastewater treatment and wastewater, which is applied in the fields of adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes to achieve the effects of low requirements for adsorption conditions, high adsorption efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030](1) Weigh 5g of peanut shells and place them in a 1L beaker, add 100mL of 1mol / L phosphoric acid solution, stir for 60min, then use a suction filter pump to remove the liquid part, dry at 50°C, and then heat up to 180°C Heating for 60 minutes, then activating in a muffle furnace at 500°C for 60 minutes, washing with 75°C deionized water to remove free phosphoric acid, then drying at 50°C and cooling to obtain phosphoric acid-modified peanut shells;

[0031] (2) Weigh 5g of sawdust and place it in a 1L beaker, mix phosphoric acid and sawdust at a ratio of 2:1, stir evenly, let it stand for 5 minutes to allow it to fully impregnate and swell, and then place it in an oven at 120-150°C to dry and solidify for 60 minutes. Stir once every 15 minutes. Then place it in a muffle furnace for activation at 500°C for 60 minutes. After the activation, pickle first, then wash with water until the rinsing solution is neutral, and then place it in a drying oven at 50°C to dry and cool t...

Embodiment 2

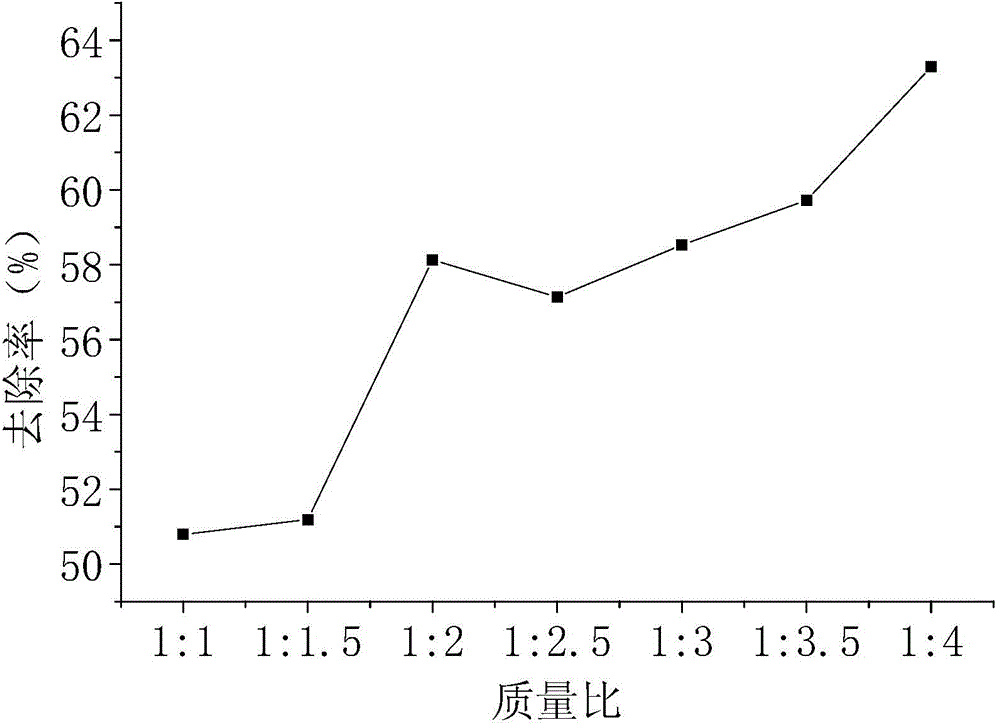

[0034] Get 100mL concentration and place the Cr(VI) solution of 10mg / L in a 250mL conical flask with a stopper, accurately weigh 0.3g of the composite adsorbent prepared in Example 1 and add it to the Cr(VI) solution. The mass ratios of permanent peanut shells and modified wood chips are 1:1, 1:1.5, 1:2, 1:2.5, 1:3, 1:3.5, 1:4, respectively. Place in a constant temperature oscillator, shake at a rate of 100 r / min at 25°C, take the supernatant after 60 min, and test the absorbance of residual Cr(VI) by the diphenylcarbazide method. After calculation, the removal rates of Cr(VI) were 50.79%, 51.19%, 58.13%, 57.14%, 58.53%, 59.72%, 63.29%.

[0035] Such as figure 1 As shown, when the mass ratio of modified peanut shells and modified wood chips is 1:1-1:2, the removal rate increases slowly. When the mass ratio of modified peanut shells and modified wood chips is 1:2-1:4, the removal rate Overall tends to be stable. Therefore, the dosage ratio is preferably 1:2 to 1:4, and 1:3.5...

Embodiment 3

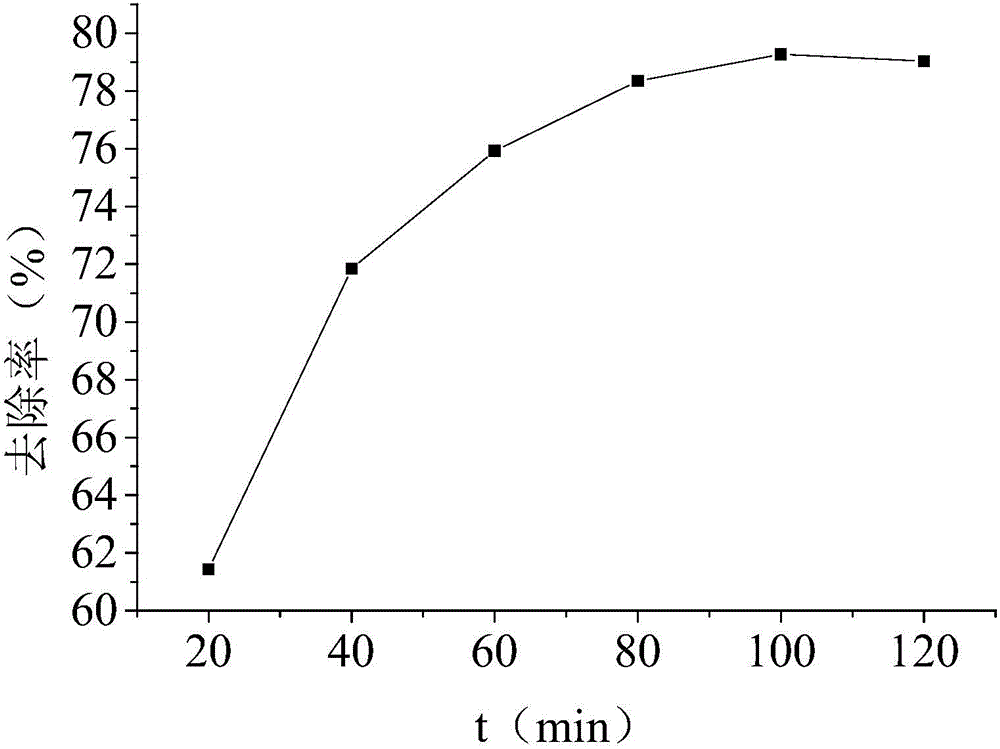

[0037] Take 100mL of 10mg / L Cr(VI) solution in a 250mL Erlenmeyer flask with a stopper, accurately weigh 0.3g of the composite adsorbent prepared in Example 1 and add it to the Cr(VI) solution, place it in a constant temperature oscillator, Oscillate at a rate of 100r / min at the temperature, take the supernatant after 20, 40, 60, 80, 100, and 120 min respectively, and test the absorbance of residual Cr(VI) by the diphenylcarbazide method. After calculation, the removal rates of Cr(VI) were 51.67%, 59.66%, 63.38%, 65.99%, 67.84%, 67.10%, respectively.

[0038] Such as figure 2 As shown, the longer the adsorption time is, the better the removal effect is, and the removal rate is faster at 20-40 minutes. After 40 minutes, the removal rate tends to be stable and reaches 100 minutes. The removal rate of Cr(VI) in wastewater is the highest, and the removal rate reaches 120 minutes. Decrease, so the optimum adsorption time is 100min, so the adsorption time range is preferably 40-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com