Device and method for anammox-heterotrophic denitrification combined ammonia nitrogen removal of coal chemical industry wastewater

A technology of heterotrophic denitrification and anaerobic ammonium oxidation, which is applied in the field of high ammonia nitrogen organic industrial wastewater treatment, can solve the problems of rare applications, achieve high-efficiency and low-consumption removal, reduce the amount of excess sludge generated, and remove high load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

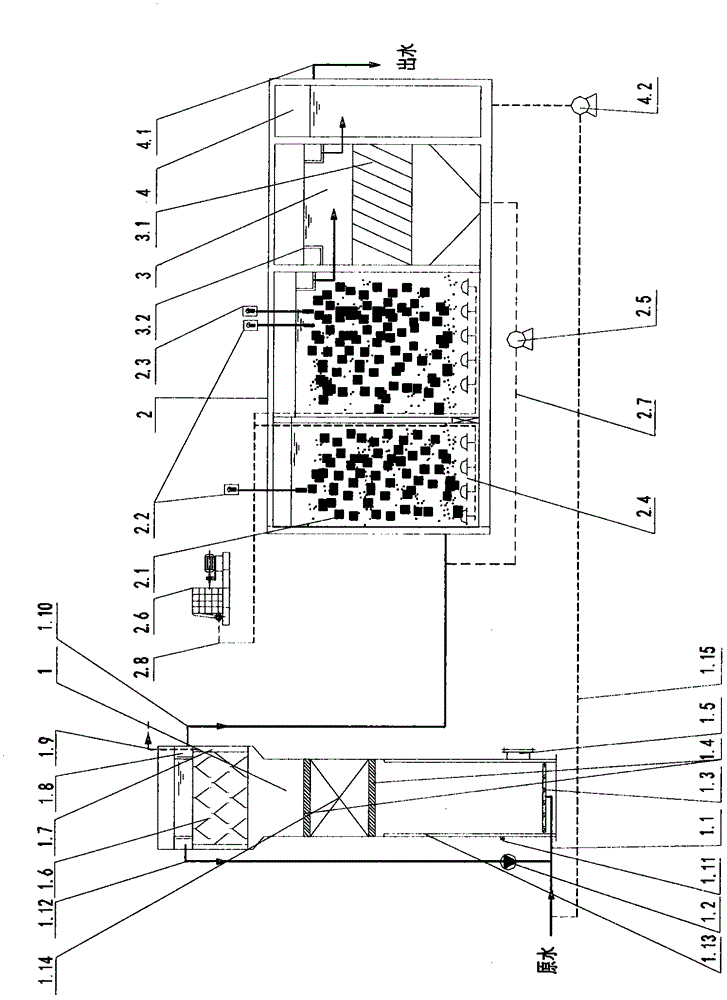

[0028]High ammonia nitrogen coal chemical wastewater anaerobic ammonium oxidation coupling heterotrophic denitrification biological denitrification treatment device: There are pre-heterotrophic denitrification tank 1, integrated anaerobic ammonium oxidation tank 2, sedimentation tank 3, and effluent tank 4.

[0029] The pre-heterotrophic denitrification tank is a cylindrical anaerobic reactor, with a water distributor 1.3 at the bottom, a raw water pipe 1.1 connected to the water distributor 1.3, and two packing brackets 1.4 at the middle and upper parts, and ethylene-propylene oxide is installed between the packing brackets Copolymerized plate packing 1.14, packing spacing 100cm, three-phase separator 1.6 is arranged on the upper part, the gas collection chamber 1.7 of the three-phase separator is connected to the exhaust pipe 1.9, and the effluent of the pre-heterotrophic denitrification tank passes through the circulating pump 1.2, the circulating pipe 1.12 and the After the...

Embodiment 2

[0033] Embodiment 2: the operating method of utilizing the above-mentioned device of the present invention:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com