Preparation method of titanium silicon carbide ceramic nozzle

A ceramic nozzle, silicon titanium carbon technology, applied in the field of refractory ceramic nozzles, to achieve the effect of reducing thermal expansion coefficient, improving thermal stability and refractory performance, and optimizing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

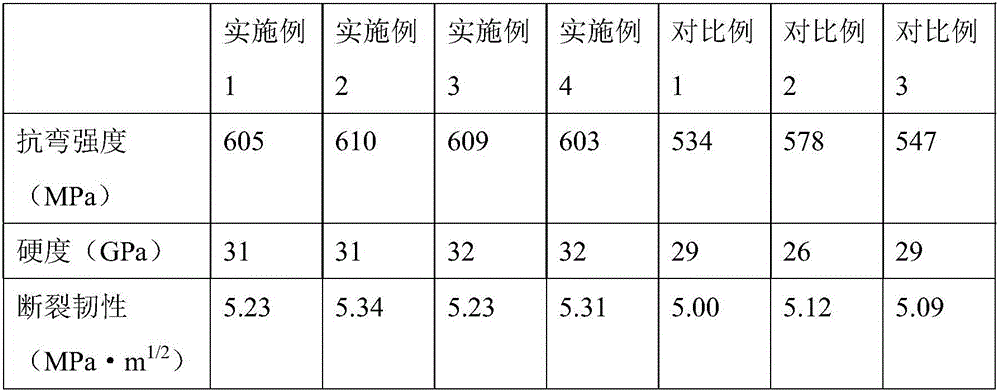

Examples

Embodiment 1

[0025] A preparation method of a silicon titanium carbon ceramic nozzle,

[0026] Including following preparation steps:

[0027] Prepare the nozzle raw material, the raw material composition of the nozzle is: 35 parts of silicon titanium carbon powder; 35 parts of corundum; 5 parts of Al-Ti alloy powder; 2 parts of phenolic resin; 2 parts of carbon tetraboride; 2 parts of silicon carbide;

[0028] Put the raw materials into the ball mill barrel and mill for 24 hours, the ball milling speed is 100r / min, the balls are YG8 hard alloy, including 6mm and 12mm balls, the ratio of big and small balls is 3:1; during ball milling, the ball-to-material ratio is 20:1; the ball milling medium is deionized water;

[0029] Pour the ball-milled slurry into a stainless steel mold with holes around it, let it stand for 1 hour, then use vacuum filtration to remove moisture, and then carry out static pressure molding with a molding pressure of 15MPa;

[0030] Put the green body into a vacuum ...

Embodiment 2

[0035] A preparation method of a silicon titanium carbon ceramic nozzle,

[0036] Including following preparation steps:

[0037] Prepare the nozzle raw material, the raw material composition of the nozzle is: 30 parts of silicon titanium carbon powder; 30 parts of corundum; 5 parts of Al-Ti alloy powder; 3 parts of phenolic resin; 2 parts of carbon tetraboride; 3 parts of silicon carbide;

[0038] Put the raw materials into the ball mill barrel and mill for 24 hours, the ball milling speed is 100r / min, the balls are YG8 hard alloy, including 6mm and 12mm balls, the ratio of big and small balls is 3:1; during ball milling, the ball-to-material ratio is 20:1; the ball milling medium is deionized water;

[0039] Pour the ball-milled slurry into a stainless steel mold with holes around it, let it stand for 1 hour, then use vacuum filtration to remove moisture, and then carry out static pressure molding with a molding pressure of 15MPa;

[0040] Put the green body into a vacuum dr...

Embodiment 3

[0045] A preparation method of a silicon titanium carbon ceramic nozzle,

[0046] Including following preparation steps:

[0047] Prepare the nozzle raw material, the raw material composition of the nozzle is: 40 parts of silicon titanium carbon powder; 40 parts of corundum; 7 parts of Al-Ti alloy powder; 7 parts of phenolic resin; 1 part of carbon tetraboride; 1 part of silicon carbide;

[0048] Put the raw materials into the ball mill barrel and mill for 24 hours, the ball milling speed is 100r / min, the balls are YG8 hard alloy, including 6mm and 12mm balls, the ratio of big and small balls is 3:1; during ball milling, the ball-to-material ratio is 20:1; the ball milling medium is deionized water;

[0049] Pour the ball-milled slurry into a stainless steel mold with holes around it, let it stand for 1 hour, then use vacuum filtration to remove moisture, and then carry out static pressure molding with a molding pressure of 15MPa;

[0050] Put the green body into a vacuum dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com