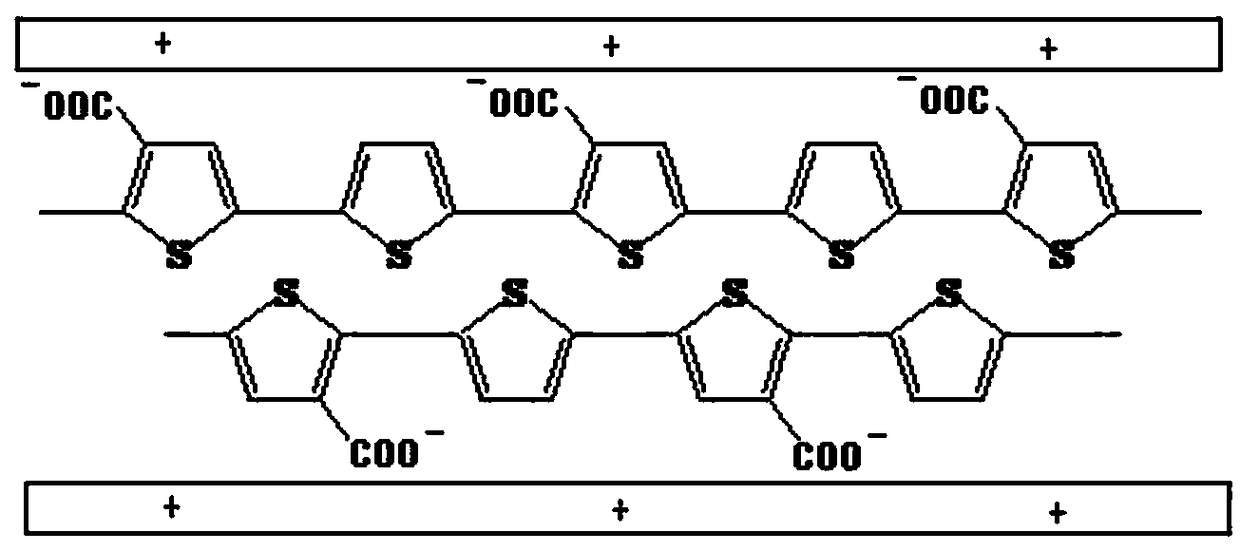

Poly3-carboxythiophene/thiophene intercalated hydrotalcite composites and its preparation process

A composite material and a preparation process technology are applied in the field of poly-3-carboxythiophene/thiophene intercalated hydrotalcite composite material and its preparation, and achieve the effects of low price, environmental protection and non-toxicity of materials, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

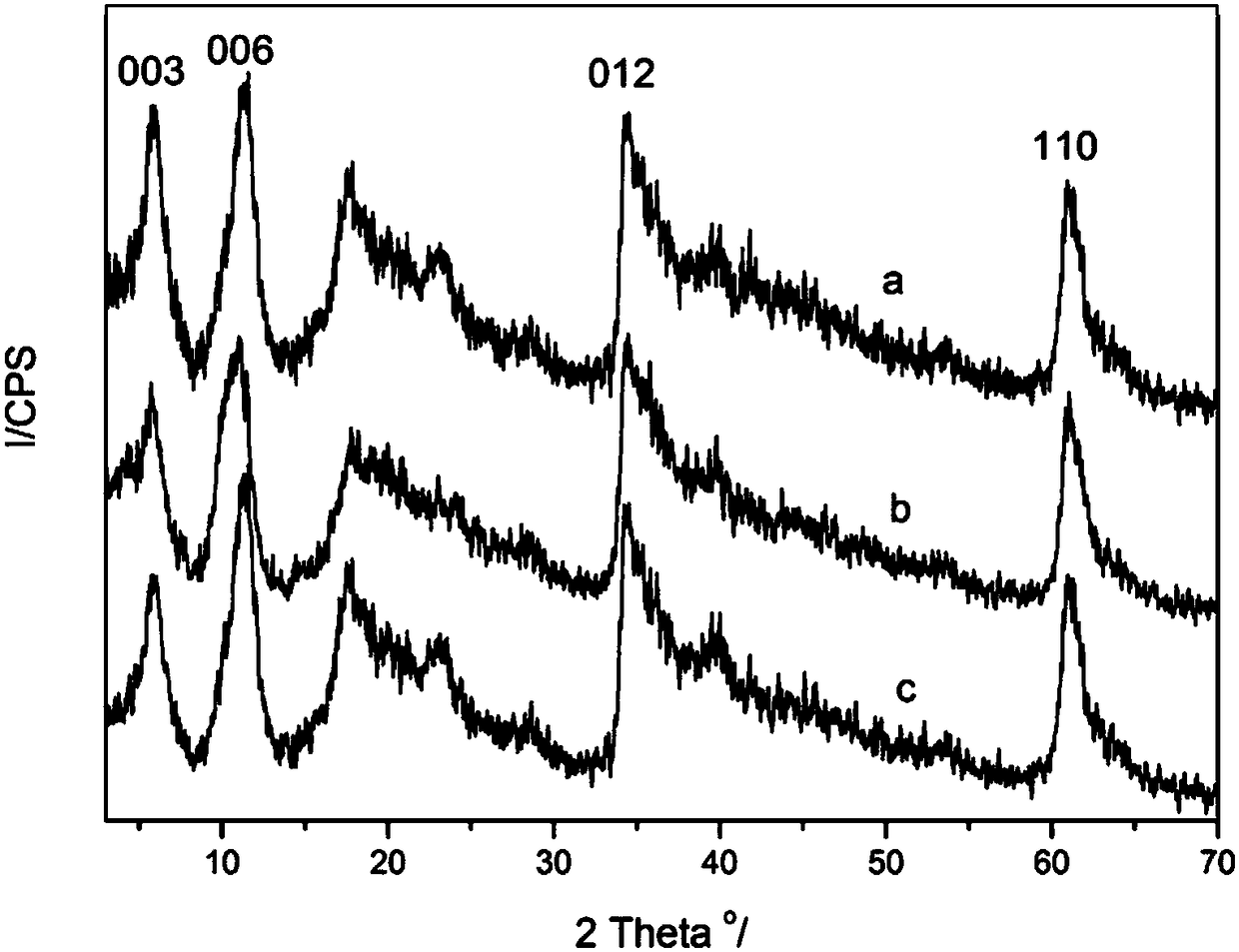

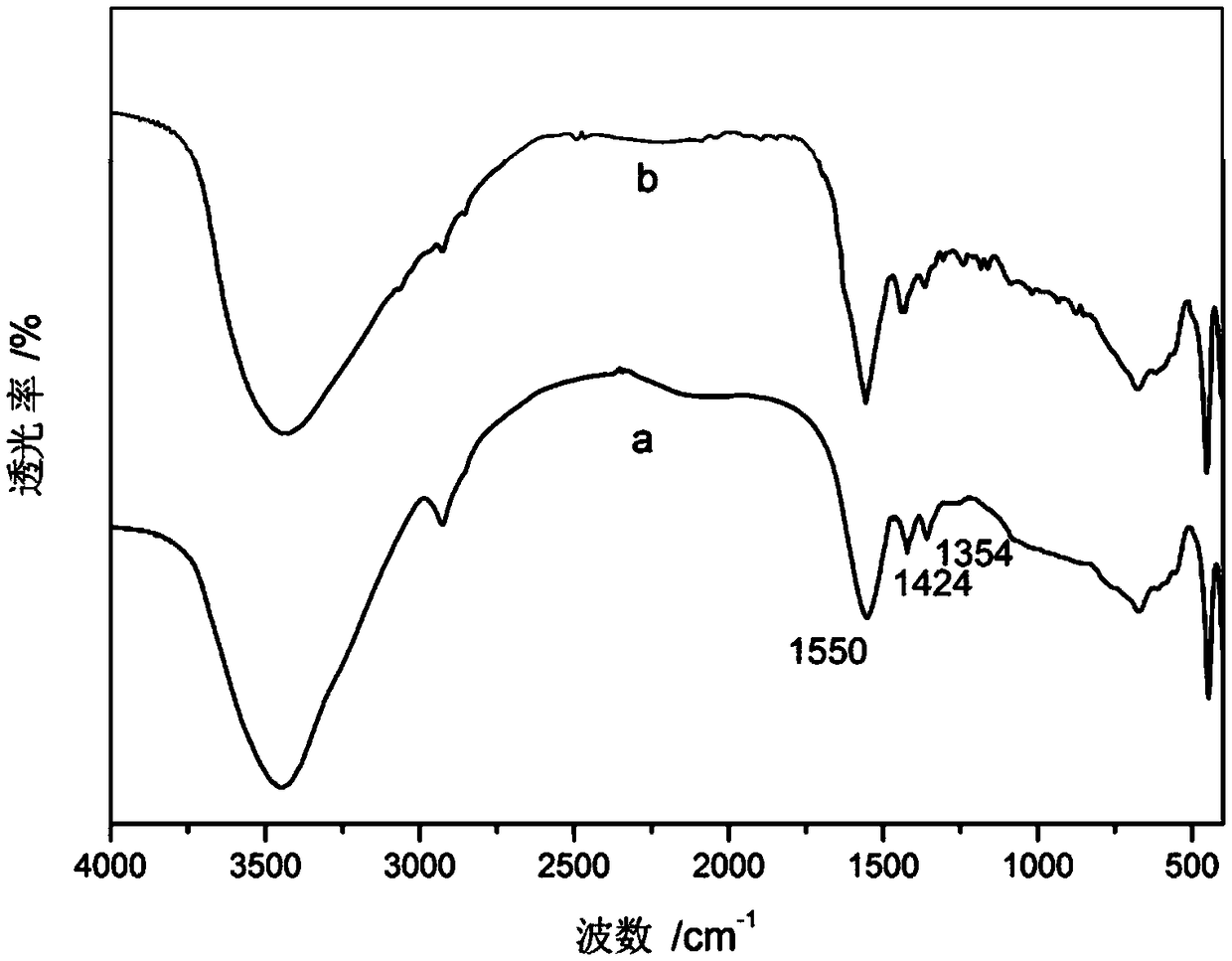

Embodiment 1

[0042] The preparation technology of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0043] (1) Weigh 17.8g Zn(NO 3 ) 2 ·6H 2 O and 11.3g Al(NO 3 ) 3 9H 2 O dissolved in 100mL to remove CO 2 Mixed salt solution was prepared in deionized water, and another 5.6g NaOH was weighed and dissolved in 50mL to remove CO 2 deionized water, at room temperature N 2 Under protection, the mixed salt solution and NaOH solution were added to the four-necked flask by double-drop method for vigorous stirring, and then the pH value was adjusted to 7 with 0.1mol / L NaOH solution, and the resulting slurry was crystallized at 60°C for 72h. The product was placed in a centrifuge, centrifuged at a speed of 2500r / min for 5min, and then used to remove CO 2 Wash with deionized water until the washing solution is neutral, and then dry it at 50°C for 48 hours to obtain the hydrotalcite precursor ZnAl-NO 3 -LDHs, where Zn 2+ with Al 3+ T...

Embodiment 2

[0052] The preparation technology of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0053] (1) Weigh 15.4g Mg(NO 3 ) 2 ·6H 2 O and 11.3g Al(NO 3 ) 3 9H 2 O dissolved in 100mL to remove CO 2 Mixed salt solution was prepared in deionized water, and another 5.6g NaOH was weighed and dissolved in 50mL to remove CO 2 deionized water, at room temperature N 2 Under protection, the mixed salt solution and NaOH solution were added to the four-necked flask by double-drop method for vigorous stirring, and then the pH value was adjusted to 10 with 5.0mol / L NaOH solution, and the resulting slurry was crystallized at 90°C for 12 hours. The product was placed in a centrifuge, centrifuged at a speed of 3500r / min for 3min, and then used to remove CO 2 Wash with deionized water until the washing solution is neutral, and then dry it at 90°C for 20 hours to obtain the hydrotalcite precursor MgAl-NO 3 -LDHs, where Mg 2+ with Al...

Embodiment 3

[0062] The preparation technology of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0063] (1) Weigh 26.7g Zn(NO 3 ) 2 ·6H 2 O and 11.3g Al(NO 3 ) 3 9H 2 O dissolved in 100mL to remove CO 2 Mixed salt solution was prepared in deionized water, and another 5.6g NaOH was weighed and dissolved in 50mL to remove CO 2 of deionized water, at room temperature N 2 Under protection, the mixed salt solution and NaOH solution were added to the four-necked flask by double-drop method for vigorous stirring, and then the pH value was adjusted to 7 with 1.0mol / L NaOH solution, and the resulting slurry was crystallized at 70°C for 48 hours. The product was placed in a centrifuge, centrifuged at a speed of 3000r / min for 4min, and then used to remove CO 2 Wash with deionized water until the washing solution is neutral, and then dry it at 70°C for 36 hours to obtain the hydrotalcite precursor ZnAl-NO 3 -LDHs, where Zn 2+ with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com