Chitosan-based hydrogel and preparation method and application thereof

A chitosan-based, chitosan-based technology, applied in the field of chitosan-based hydrogel and its preparation, can solve the problems of poor plasticity, long reaction cycle, harsh operating conditions, etc., to improve mechanical strength and plasticity, plasticity Strong and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a chitosan-silver hydrogel, which comprises the following components:

[0043] Chitosan, 0.2 parts by weight;

[0044] Silver, 0.25 parts by weight;

[0045] Water, 99.55 parts by weight.

[0046] Described chitosan-silver hydrogel is prepared by the following method:

[0047] (1) Weigh 0.15mol of AgNO 3 Dissolve in 1L of water to prepare AgNO with a concentration of 0.15mol / L 3 solution;

[0048] (2) take by weighing 4mg chitosan and be dissolved in the acetic acid solution that 1ml concentration is 1wt%, prepare the chitosan solution that concentration is 0.4wt%, measure the described chitosan solution of 0.4ml, add 0.4ml deionized Water and 0.1ml of NaOH solution with a concentration of 0.1mol / L to adjust the pH to 3.47, and then quickly inject 0.1ml of the AgNO 3 Solution, shake quickly for 2 seconds to obtain chitosan-silver hydrogel.

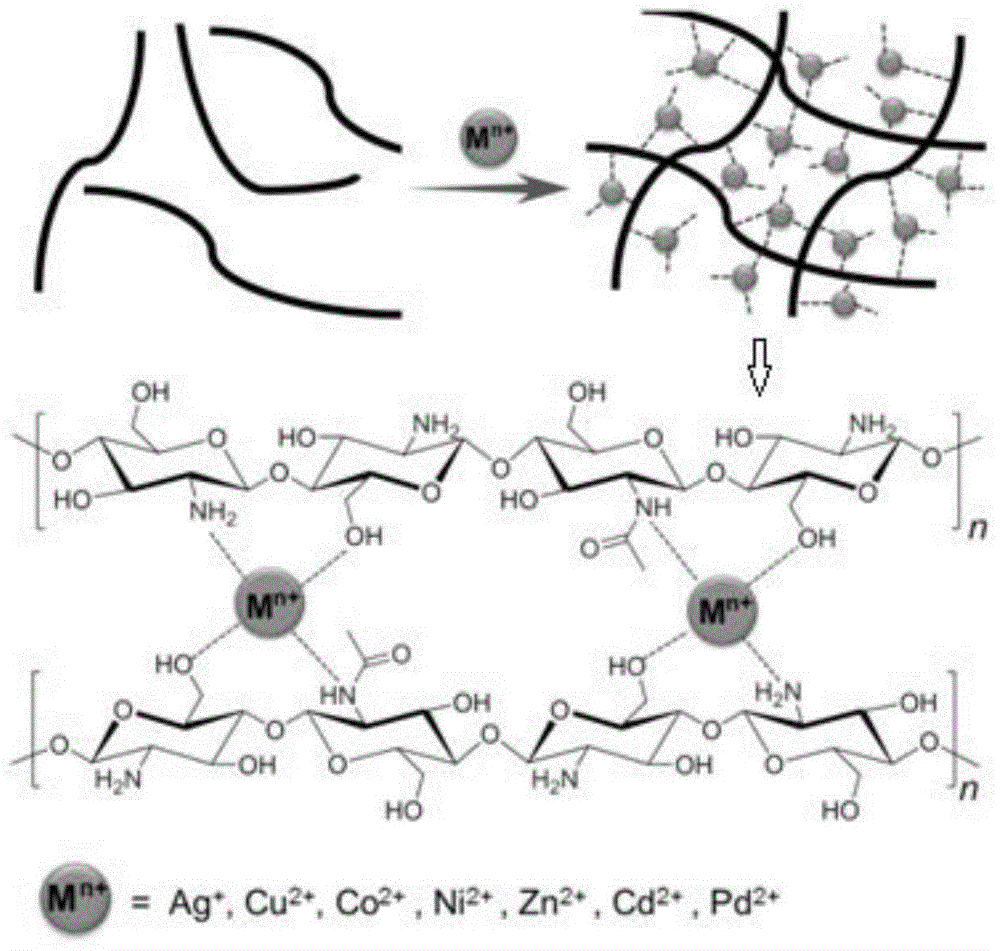

[0049] Please refer to the specific reaction mechanism figure 1 , is the reaction mechanis...

Embodiment 2

[0056] The present embodiment provides a chitosan-cobalt hydrogel, which comprises the following components:

[0057] Chitosan, 0.4 parts by weight;

[0058] Cobalt, 0.25 parts by weight;

[0059] Water, 99.35 parts by weight.

[0060] Described chitosan-cobalt hydrogel adopts following method to prepare:

[0061] (1) Weigh 0.5mol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 1L of water to prepare Co(NO 3 ) 2 solution;

[0062] (2) taking by weighing 10mg chitosan and being dissolved in 1ml concentration is in the acetic acid solution of 1wt%, and preparation obtains the chitosan solution that concentration is 1.0wt%;

[0063] Measure the chitosan solution described in 0.4ml, add 0.25ml deionized water and 0.25ml concentration to be the NaOH solution of 0.1mol / L, be 3.7 to adjust pH, inject 0.1ml described Co(NO 3 ) 2 Solution, shake quickly for 2 seconds to obtain chitosan-cobalt hydrogel.

Embodiment 3

[0065] The present embodiment provides a chitosan-copper hydrogel, which comprises the following components:

[0066] Chitosan, 4.0 parts by weight;

[0067] Copper, 10.0 parts by weight;

[0068] Water, 85 parts by weight.

[0069] Described chitosan-copper hydrogel is prepared by the following method:

[0070] (1) Weigh 0.5mol of Cu(NO 3 ) 2 Dissolved in 1L of water to prepare Cu(NO 3 ) 2 solution;

[0071] (2) taking by weighing 40mg chitosan and being dissolved in 1ml concentration is in the acetic acid solution of 1wt%, and preparation obtains the chitosan solution that concentration is 4.0wt%;

[0072] Measure the chitosan solution described in 0.4ml, add 0.25ml deionized water and 0.25ml concentration to be the NaOH solution of 0.1mol / L, be 6.2 to regulate pH, inject the described Cu(NO 3 ) 2 Solution, shake quickly for 2 seconds to obtain chitosan-copper hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com