Carbon nano environment-friendly rubber composite and preparation method thereof

A technology of carbon nanomaterials and environmentally friendly rubber, which is applied in the field of rubber products, can solve the problem that reclaimed rubber regenerated carbon black cannot be fully utilized, and achieve the effect of promoting a virtuous cycle, low cost, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The carbon nano-environmentally friendly rubber composite material of the present invention is composed of the following raw materials in parts by weight: 100 parts of rubber, 3.5 parts of carbon nano-rubber masterbatch, 50 parts of regenerated carbon black, 2.5 parts of sulfur, 2.5 parts of anti-aging agent, and 1 part of zinc oxide. , stearic acid 2, accelerator 1.25.

[0023] The carbon nano material is carbon nano tube or graphene; the carbon nano rubber masterbatch is a pre-dispersed product of carbon nano material with rubber as a carrier; the rubber is natural rubber and butadiene rubber.

[0024] The preparation method of carbon nano-environmental protection rubber composite material of the present invention is as follows:

[0025] Put the rubber into the open mill for masticating, cover the rolls, add compounding agent and regenerated carbon black in sequence, after mixing evenly, add carbon nano-rubber master batches for mixing, and finally add sulfur and mix ...

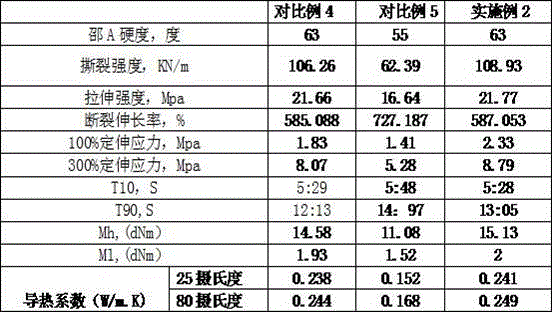

Embodiment 2

[0034] The carbon nano-environmentally friendly rubber composite material of the present invention is composed of the following raw materials in parts by weight: 100 parts of rubber, 5 parts of carbon nano-rubber masterbatch, 50 parts of regenerated carbon black, 30 parts of regenerated rubber powder, 1.5 parts of sulfur, and anti-aging agent 2. Zinc oxide 2.5, stearic acid 1, accelerator 1.

[0035] The carbon nano material is carbon nano tube or graphene; the carbon nano rubber masterbatch is a pre-dispersed product of carbon nano material with rubber as a carrier; the rubber is natural rubber and butadiene rubber.

[0036] The preparation method of carbon nano-environmental protection rubber composite material of the present invention is as follows:

[0037] After putting the rubber into the internal mixer for masticating, add compounding agent, reclaimed rubber powder, and regenerated carbon black in sequence, and after mixing evenly, add carbon nano-rubber masterbatch to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com