Low-gloss high-strength halogen-free flame retardant PC/ASA blending material and preparation method thereof

A low-gloss, high-strength technology, applied in the field of plastic blending, can solve the problems of deteriorating the mechanical properties of materials, inability to meet the requirements of materials, etc., achieving excellent flame retardant effect, easy implementation, and less harm to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

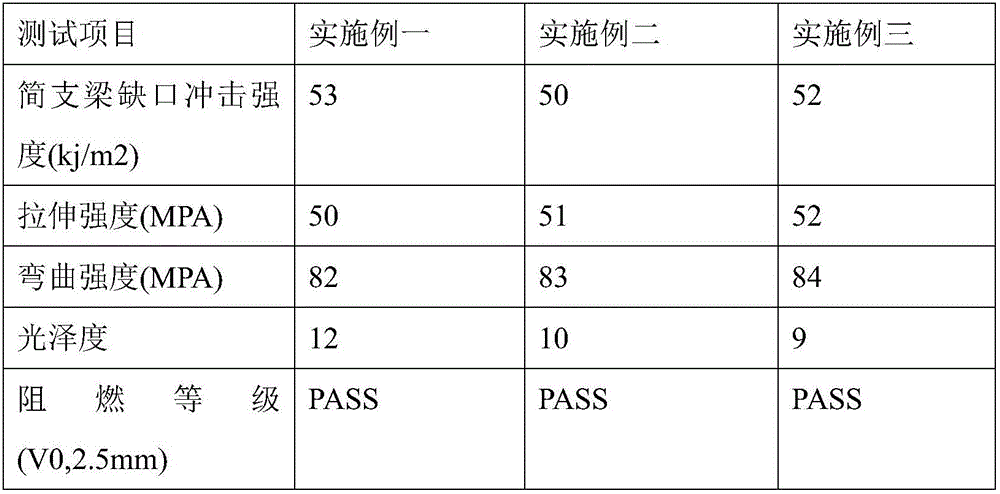

Examples

Embodiment 1

[0031] A low-gloss, high-strength, halogen-free flame-retardant PC / ASA blend material, including the following weight ratio raw materials:

[0032] PC: 80 parts, ASA: 10 parts, halogen-free flame retardant: 20 parts, toughening agent: 10 parts, low gloss agent: 1 part, compatibilizer: 1 part, anti-dripping agent: 0.1 part, antioxidant Agent: 1.8 parts, UV absorber: 0.2 parts, lubricant: 0.2 parts.

[0033] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0034] Further, the halogen-free flame retardant includes one or more of organosiloxane flame retardants, inorganic hydroxide flame retardants, sulfonate flame retardants, phosphorus flame retardants, nitrogen flame retardants kind.

[0035] T...

Embodiment 2

[0049] A low-gloss, high-strength, halogen-free flame-retardant PC / ASA blend material, including the following weight ratio raw materials:

[0050] PC: 70 parts, ASA: 15 parts, halogen-free flame retardant: 16 parts, toughening agent: 7 parts, low gloss agent: 7 parts, compatibilizer: 5 parts, anti-dripping agent: 0.3 parts, antioxidant Agent: 1.3 parts, UV absorber: 1.1 parts, lubricant: 0.5 parts.

[0051] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0052] Further, the halogen-free flame retardant includes one or more of organosiloxane flame retardants, inorganic hydroxide flame retardants, sulfonate flame retardants, phosphorus flame retardants, nitrogen flame retardants kind.

[0053]...

Embodiment 3

[0067] A low-gloss, high-strength, halogen-free flame-retardant PC / ASA blend material, including the following weight ratio raw materials:

[0068] PC: 50 parts, ASA: 30 parts, halogen-free flame retardant: 10.4 parts, toughening agent: 2 parts, low gloss agent: 9 parts, compatibilizer: 2.5 parts, anti-dripping agent: 0.8 parts, antioxidant Agent: 0.2 parts, UV absorber: 2 parts, lubricant: 1.8 parts.

[0069] Further, the PC is a mixture of different bisphenol A polycarbonates. By mixing different bisphenol A polycarbonates, a polycarbonate mixture with better comprehensive performance is obtained, so that it not only has higher mechanical properties and Thermodynamic properties, but also its high fluidity, good processing performance.

[0070] Further, the halogen-free flame retardant includes one or more of organosiloxane flame retardants, inorganic hydroxide flame retardants, sulfonate flame retardants, phosphorus flame retardants, nitrogen flame retardants kind.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com