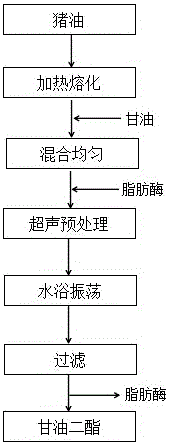

Method for preparing diglyceride through lard glycerolysis catalysis by power ultrasonic pretreatment enzyme method

A technology of ultrasonic pretreatment and diglyceride is applied in the field of preparing diglyceride, and power ultrasonic pretreatment enzyme catalyzes the hydrolysis of lard glycerol to prepare diglyceride, so as to improve the speed and yield, increase the value of by-products, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Take a certain amount of lard and put it in a water bath to completely melt it, then mix it with glycerin in a conical flask according to 1:1 (molar ratio);

[0021] 2. Add 4% lard weight of immobilized lipase Lipozyme RMIM to the mixture of lard and glycerin, place the Erlenmeyer flask in a constant temperature water bath, insert the ultrasonic probe about 5 mm below the reaction solution, and ultrasonically Under the conditions of temperature and ultrasonic power of 200 W, ultrasonic treatment was performed at a certain stirring speed for 5 min, transferred to a constant temperature oscillator in a water bath, and reacted at 50 °C and a stirring speed of 150 r / min for 4 h;

[0022] Three, filter and remove lipase from above-mentioned reaction mixture, promptly make the fat containing diglyceride;

[0023] Four, utilize thin layer chromatography to carry out qualitative analysis to the composition of gained reaction mixture, utilize normal phase high performance liq...

Embodiment 2

[0025] 1. Take a certain amount of lard and put it in a water bath to completely melt it, then mix it with glycerin in a conical flask according to 1:1 (molar ratio);

[0026] 2. Add 3% lard weight of immobilized lipase Lipozyme RMIM to the mixture of lard and glycerin, place the Erlenmeyer flask in a constant temperature water bath, insert the ultrasonic probe about 5 mm below the reaction solution, and ultrasonically Under the conditions of temperature and ultrasonic power of 200 W, ultrasonic treatment was performed at a certain stirring speed for 5 min, transferred to a constant temperature oscillator in a water bath, and reacted at 50 °C and a stirring speed of 150 r / min for 4 h;

[0027] Three, filter and remove lipase from above-mentioned reaction mixture, promptly make the fat containing diglyceride;

[0028] Four, utilize thin layer chromatography to carry out qualitative analysis to the composition of gained reaction mixture, utilize normal phase high performance liq...

Embodiment 3

[0030] 1. Take a certain amount of lard and put it in a water bath to completely melt it, then mix it with glycerin in a conical flask according to 1:1 (molar ratio);

[0031] 2. Add 3% lard weight of immobilized lipase Lipozyme RMIM to the mixture of lard and glycerin, place the Erlenmeyer flask in a constant temperature water bath, insert the ultrasonic probe about 5 mm below the reaction solution, and ultrasonically Temperature and ultrasonic power of 250 W, ultrasonic treatment at a certain stirring speed for 5 minutes, transferred to a constant temperature oscillator in a water bath, and reacting for 4 hours at 50 °C and a stirring speed of 150 r / min;

[0032] Three, filter and remove lipase from above-mentioned reaction mixture, promptly make the fat containing diglyceride;

[0033] 4. Utilize thin-layer chromatography to qualitatively analyze the composition of the resulting reaction mixture, and utilize normal phase high-performance liquid chromatography to quantitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com