Salt bath niobium infiltrating agent and niobium infiltrating method for metal titanium surface

A technology of metal titanium and salt bath, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor flexibility, high cost, poor industrial practicability, etc., and achieve the effect of good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for infiltration of niobium on the surface of titanium metal in a salt bath, which includes preparation of an infiltration agent, surface pretreatment of the workpiece, pretreatment of the infiltration agent, niobium infiltration treatment and cleaning of the workpiece.

[0029] The preparation of osmotic agent refers to 840 grams of anhydrous borax 2 B 4 O 7 ), 100 grams of niobium oxide (Nb 2 O 5 ) And 60 grams of silicon carbide (SiC) are mixed uniformly and placed in a 120 ℃ oven for 40 minutes to obtain the required metal titanium surface salt bath niobium agent for use. Among them, silicon carbide is commercially available green and pure silicon carbide with a particle size of 150-200 The purity of niobium oxide is at least 99.5%;

[0030] The surface pretreatment of the workpiece is to cut the TC4 titanium alloy bar into a profile of 10mm×12mm×3mm for use. The surface of the cut titanium metal is cleaned with degreasing and deionized water, and then polished ...

Embodiment 2

[0036] The method is basically the same as in Example 1, except that the niobium infiltration agent formula used is composed of 840 grams of Na 2 B 4 O 7 (Accounting for 84%), 100 grams of Nb 2 O 5 (10%), 60 grams of SiC (6%).

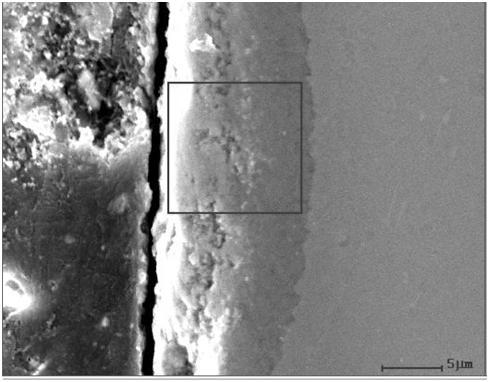

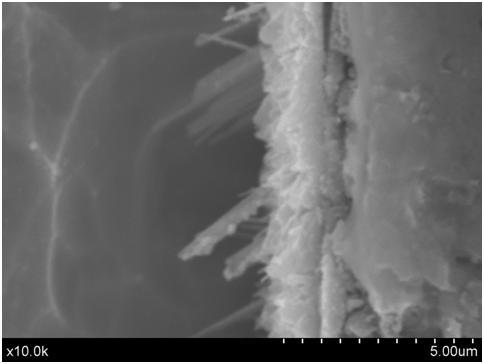

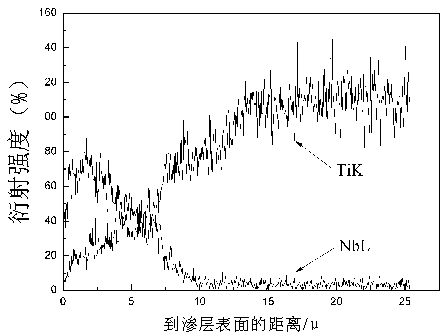

[0037] Test after taking out the sample. The thickness of the seepage layer is 1.6μm ( figure 2 ); The surface hardness of the niobium layer is 1155HV, which is about 3.5 times the hardness of the substrate.

Embodiment 3

[0039] The method is basically the same as that of Example 1, except that the niobium infiltration method used has a temperature of 1000°C.

[0040] After taking out the sample and testing, the surface hardness of the niobium infiltration layer is 1071.8HV, which is about 3.2 times the hardness of the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com