Method for loading carbon fiber surface with carbon nanotubes

A technology of carbon nanotubes and surface loading, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., which can solve the problem that the grafting efficiency of carbon nanotubes is not clearly reflected, the superiority of large-scale production cannot be reflected, and it is not easy to produce large-scale, etc. problem, to achieve the effects of obvious load efficiency, low cost, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

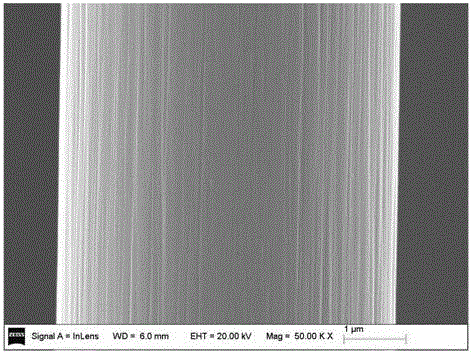

[0027] Set up a washing tank in the washing section of the carbon fiber tow. The washing tank contains a solution of aminated carbon nanotubes. The diameter of the carbon nanotubes is 10nm to 20nm, and the length is ≤5μm. It is ultrasonically dispersed in deionized water to make a concentration of 0.05wt. .% solution; a carbon nanotube dust chamber is set between the sizing and drying sections of the carbon fiber tow, the air velocity in the dust chamber is 2m / s, and the feeding speed is 0.001g / min. After the production process conditions are set, a carbon fiber product with carbon nanotubes loaded on the surface is obtained in a continuous production process.

[0028] Prepare epoxy resin-based composite material with this carbon fiber product, carbon fiber volume content is controlled at 65%, and the composite material interlaminar shear strength that obtains reaches 94MPa, and in the split surface of composite material, a large amount of resin ( Figure 4 ), indicating that ...

Embodiment 2

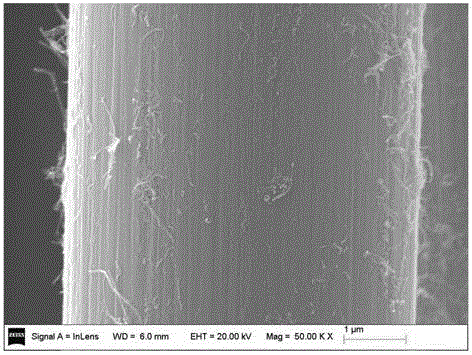

[0030] Set up a washing tank in the washing section of the carbon fiber tow. The washing tank contains an aminated carbon nanotube solution with a diameter of 10nm-20nm and a length of ≤5μm, which is ultrasonically dispersed in deionized water to make a concentration of 0.03wt. .% solution; a carbon nanotube dust chamber is set between the sizing and drying sections of the carbon fiber tow, the air velocity in the dust chamber is 1.5m / s, and the feeding speed is 0.001g / min. After the production process conditions are set, a carbon fiber product with carbon nanotubes loaded on the surface is obtained in a continuous production process.

[0031] The carbon fiber product is used to prepare an epoxy resin-based composite material, and the carbon fiber volume content is controlled at 70%, and the interlaminar shear strength of the obtained composite material reaches 97MPa; the interlaminar shear strength of the carbon fiber epoxy resin-based composite material without carbon nanotub...

Embodiment 3

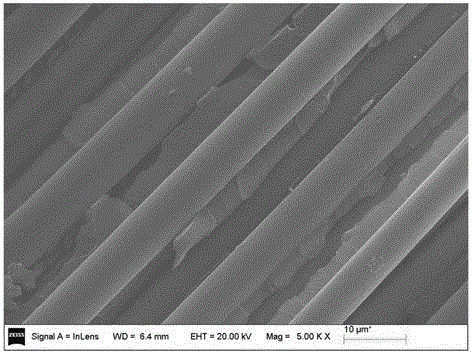

[0033] Set up a washing tank in the washing section of the carbon fiber tow. The washing tank contains a solution of carboxylated carbon nanotubes. The diameter of the carbon nanotubes is 10nm-20nm and the length is ≤5μm. It is ultrasonically dispersed in deionized water to make a concentration of 0.05wt. % solution; a carbon nanotube dust chamber A is set between the sizing and drying sections of the carbon fiber tow, the air velocity in the dust chamber A is 2.5m / s, and the feeding speed is 0.002g / min. After the production process conditions are set, a carbon fiber product with carbon nanotubes loaded on the surface is obtained in a continuous production process.

[0034] The carbon fiber product is used to prepare epoxy resin-based composite materials, the carbon fiber volume content is controlled at 60%, and the interlaminar shear strength of the obtained composite material reaches 89MPa; Cut to 79MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com