Composite paper for absorbing volatile organic chemicals (VOCs) industrial waste gas, and manufacturing method of composite paper

A technology for industrial waste gas and composite paper, applied in special paper, separation method, tissue paper/absorbent paper, etc., can solve problems such as increased production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

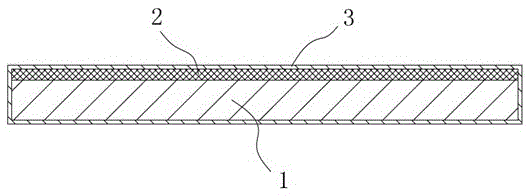

[0021] Such as figure 1 As shown, a composite paper for VOCs industrial waste gas adsorption includes a base carrier 1, the base carrier 1 is made of glass fiber, and the specification of the glass fiber used is 10-30 g / square meter.

[0022] The base carrier 1 is coated with a slurry composite coating 2 . The slurry coating 2 is an aqueous PU slurry, and the mass ratio of each component in the slurry is: calcium carbonate 2.5, molecular sieve 20, 50% solid-containing aqueous PU 2.5, water 75, wherein the molecular sieve and calcium carbonate particle size D50 1-10um, the pH value of the slurry is 5-6, the viscosity of the slurry is 800-1500mPa.s, and the loading capacity of the finally obtained slurry coating 2 is 50-70g / square meter.

[0023] The base carrier 1 and the slurry coating 2 constitute an inner layer of composite paper, and the inner layer of composite paper is covered with a fiber outer layer 3 made of natural fibers or synthetic fibers. The thickness of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com