Fast qualitative filter paper and preparing method thereof

A qualitative filter paper, rapid technology, applied in the field of filter paper, can solve the problems of high residual ash, paper leakage, and reduced filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

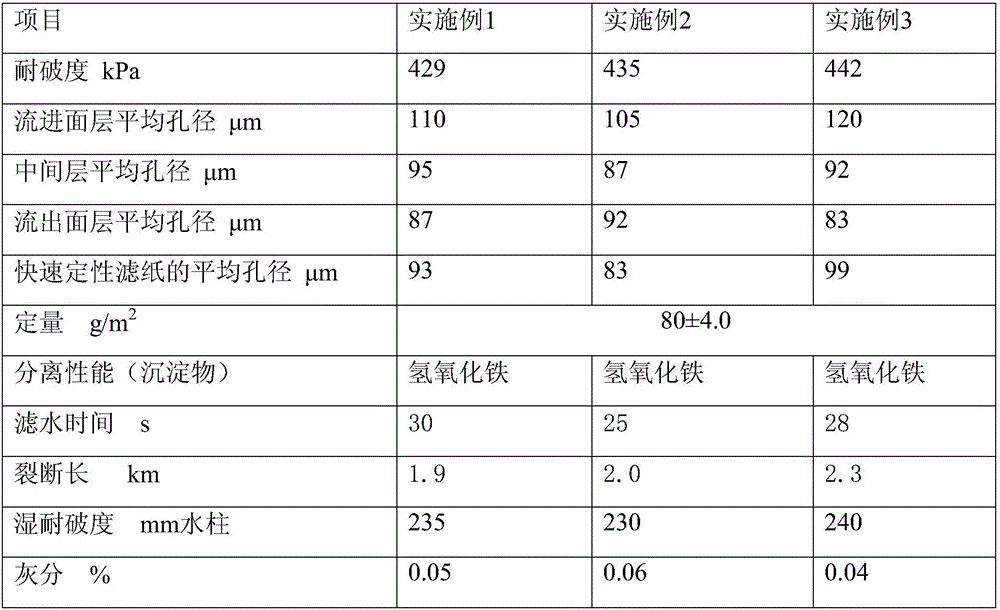

Examples

Embodiment 1

[0024] A rapid qualitative filter paper, which has a three-layer structure from the inflow surface to the outflow surface of the filter paper, the middle layer of the three-layer structure includes 20 parts of viscose fiber, 30 parts of alkali-treated cotton short Fluff pulp, 1 part of dispersant, 1 part of wet strength agent; the described flow-in surface layer includes 10 parts of acetate fiber, 30 parts of flax fiber, 0.2 part of water repellent, and 0.5 part of wet strength agent; The outflow surface layer includes 10 parts of polypropylene fibers, 30 parts of bamboo fibers, and 0.2 parts of waterproofing agent in parts by weight; the described dispersant is carboxymethyl cellulose; the described wet strength agent is polystyrene Amide polyepichlorohydrin resin; the waterproofing agent is selected from melamine resin, and the α-cellulose content in the rapid qualitative filter paper is 95%.

[0025] The preparation method of above-mentioned fast qualitative filter paper, c...

Embodiment 2

[0033] A rapid qualitative filter paper, which is a three-layer structure from the inflow surface to the outflow surface of the filter paper, the middle layer of the three-layer structure includes 40 parts of viscose fiber, 80 parts of alkali-treated cotton Short fluff pulp, 3 parts of dispersant, 2 parts of wet strength agent; the described flow-in surface layer includes 30 parts of acetate fiber, 60 parts of flax fiber, 2 parts of water repellent, 2 parts of wet strength agent ; The outflow surface layer includes 30 parts by weight of polypropylene fiber, 80 parts of bamboo fiber, and 2 parts of water repellent; the described dispersant is sodium pyrophosphate; the described wet strength agent is polyamide Polyepichlorohydrin resin; the waterproofing agent is waterproof slurry, and the α-cellulose content in the rapid qualitative filter paper is 98%.

[0034] The preparation method of above-mentioned fast qualitative filter paper, comprises the steps:

[0035] 1) Prepare th...

Embodiment 3

[0042]A rapid qualitative filter paper, which is a three-layer structure from the inflow surface to the outflow surface of the filter paper, the middle layer of the three-layer structure includes 30 parts of viscose fiber, 60 parts of alkali-treated cotton short Fluff pulp, 2 parts of dispersant, 1 part of wet strength agent; the described flow-in surface layer includes 20 parts of acetate fiber, 50 parts of flax fiber, 1 part of waterproofing agent, and 1 part of wet strength agent in parts by weight; The outflow surface layer includes 20 parts by weight of polypropylene fiber, 60 parts of bamboo fiber, and 1 part of water repellent; the described dispersant is sodium hexametaphosphate; the described wet strength agent is polyamide Polyepichlorohydrin resin; the waterproofing agent is urea-formaldehyde resin, and the α-cellulose content in the rapid qualitative filter paper is 97%.

[0043] The preparation method of above-mentioned fast qualitative filter paper, comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com