Solid-state high-pressure mixed hydrogen storage device

A high-pressure mixing and hydrogen storage device technology, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, container filling methods, etc. Mixed into the heat transfer of thermally conductive fibers to avoid aging, reduce weight, improve hydrogen storage density and dynamic response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

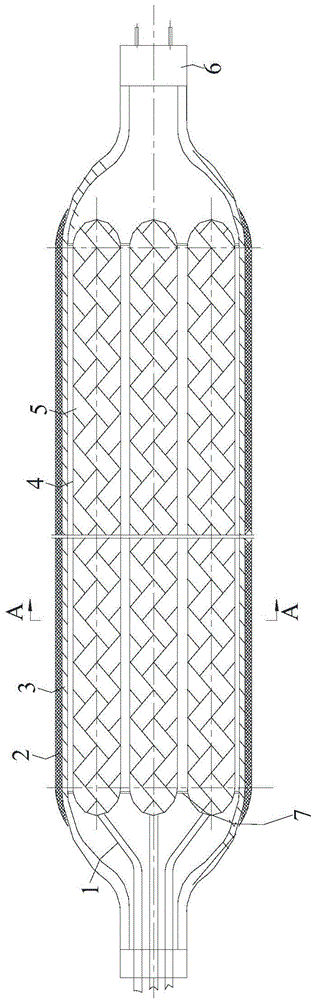

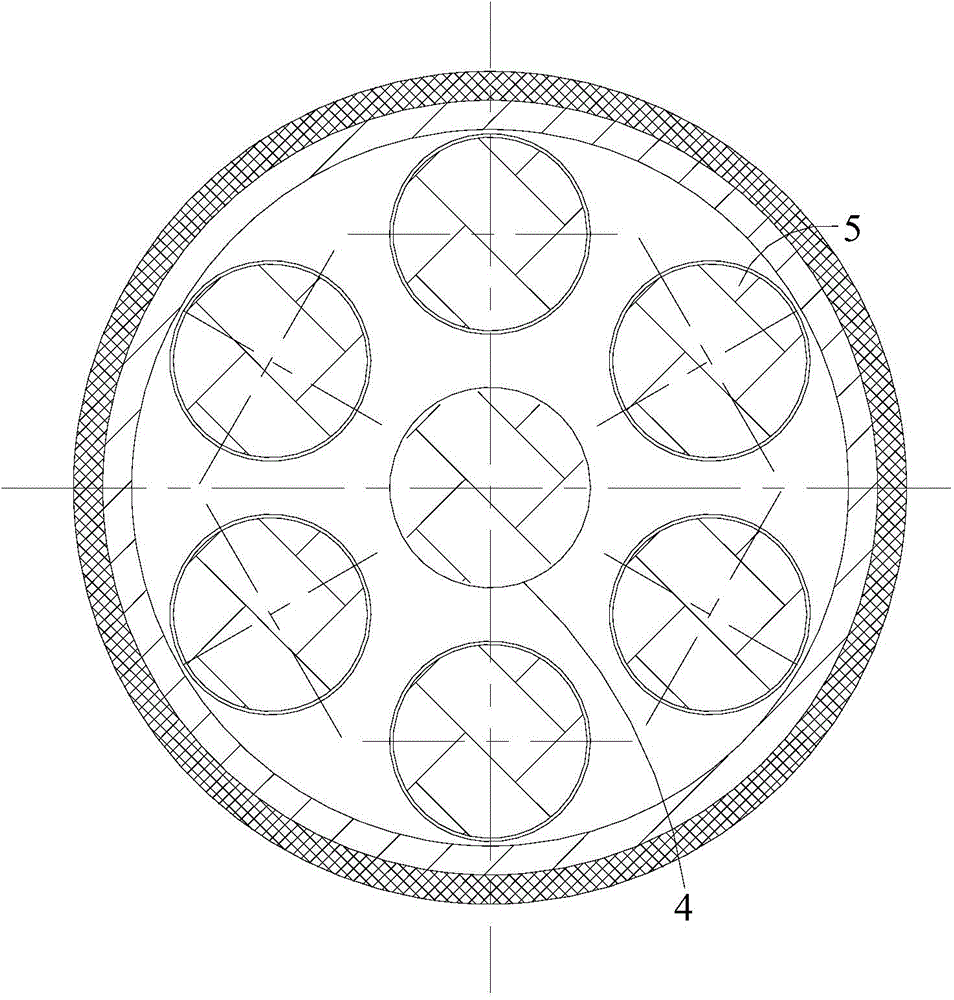

[0020] A specific embodiment of a solid-state high-pressure hybrid hydrogen storage device of the present invention, such as Figure 1-2 As shown, for example, the hydrogen storage device includes a mother tank and seven sub-tanks 4 . Wherein, the mother tank is composed of a mother tank liner 3 and a fiber winding layer 2 outside the steel liner. The inner liner 3 of the mother tank is a seamless steel pipe with both ends necked and spun into one piece. The fiber winding layer 2 can be formed by impregnating carbon fibers, glass fibers, or composite fibers in epoxy resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com