Complete feed prepared through blending of hypsizygus marmoreus residues for mutton sheep in stage of fattening

A full-price feed, seafood mushroom technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of shortage, environmental pollution, mold and pest breeding, etc., to solve the problem of reuse, the source of raw materials is wide, and the production is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

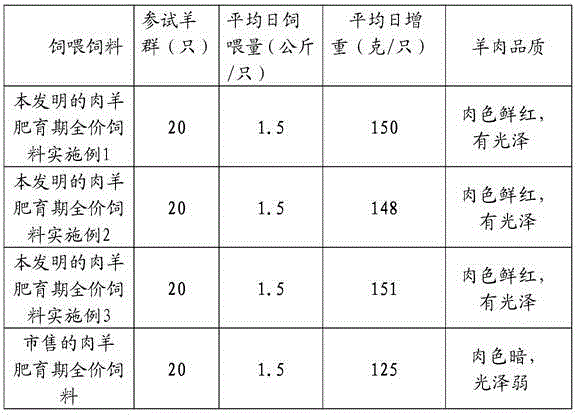

Examples

Embodiment 1

[0026] A full-price feed for mutton sheep during the fattening period prepared by using seafood and mushroom dregs, characterized in that it is mainly prepared from the following raw materials according to the following weight ratio: 25 parts of seafood mushroom dregs fermented material, 15 parts of cassia grass powder , 10 parts of pennisetum straw pulp, 10 parts of ammonified chaff bran, 1 part of soybean meal, 0.1 part of salt, 5 parts of corn flour, 0.5 part of fish bone meal, and 2 parts of hawthorn powder; among them,

[0027] The seafood mushroom dregs fermented material is made by mixing the following raw materials according to the following weight proportions, bagging and sealing, and fermenting at room temperature for 25 days: 100 parts of seafood mushroom dregs, 0.15 parts of fermentation bacteria agent and water, wherein the content of water accounts for three 65% of the total weight; said seafood mushroom slag refers to the waste culture material after the seafood ...

Embodiment 2

[0036] A full-price feed for mutton sheep during the fattening period prepared by using seafood mushroom dregs, characterized in that it is mainly prepared from the following raw materials according to the following weight ratio: 30 parts of seafood mushroom dregs fermented material, 20 parts of cassia grass powder , 15 parts of pennisetum straw pulp, 15 parts of ammoniated chaff bran, 2 parts of soybean meal, 0.2 part of salt, 3 parts of corn flour, 1.0 part of fish bone meal, and 3 parts of hawthorn powder; among them,

[0037] The seafood mushroom dregs fermented material is made by mixing the following raw materials according to the following weight proportions, bagging and sealing, and fermenting at room temperature for 25 days: 100 parts of seafood mushroom dregs, 0.05 parts of fermentation bacteria agent and water, wherein the content of water accounts for three 70% of the total weight; said seafood mushroom slag refers to the waste culture material after the seafood mus...

Embodiment 3

[0046] A full-price feed for mutton sheep during the fattening period prepared by using seafood mushroom dregs, characterized in that it is mainly prepared from the following raw materials according to the following weight ratio: 27 parts of seafood mushroom dregs fermented material, 18 parts of cassia grass powder , 12 parts of pennisetum straw pulp, 12 parts of ammoniated chaff bran, 1.5 parts of soybean meal, 0.15 part of salt, 4 parts of corn flour, 0.7 part of fish bone meal, and 2.5 parts of hawthorn powder; among them,

[0047] The seafood mushroom dregs fermentation material is made by mixing the following raw materials according to the following weight proportions, bagging and sealing, and fermenting at room temperature for 22 days: 100 parts of seafood mushroom dregs, 0.1 part of fermentation bacteria agent and water, of which the moisture content accounts for three 75% of the total weight; the seafood mushroom residue refers to the waste culture material after the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com